Joerns Hoyer User manual

Other Joerns Medical Equipment manuals

Joerns

Joerns Oxford Elevate Operator's manual

Joerns

Joerns Oxford Stature User manual

Joerns

Joerns Hoyer HPL450 User manual

Joerns

Joerns ACX Series Troubleshooting guide

Joerns

Joerns HPL400 User manual

Joerns

Joerns Chauffeur Troubleshooting guide

Joerns

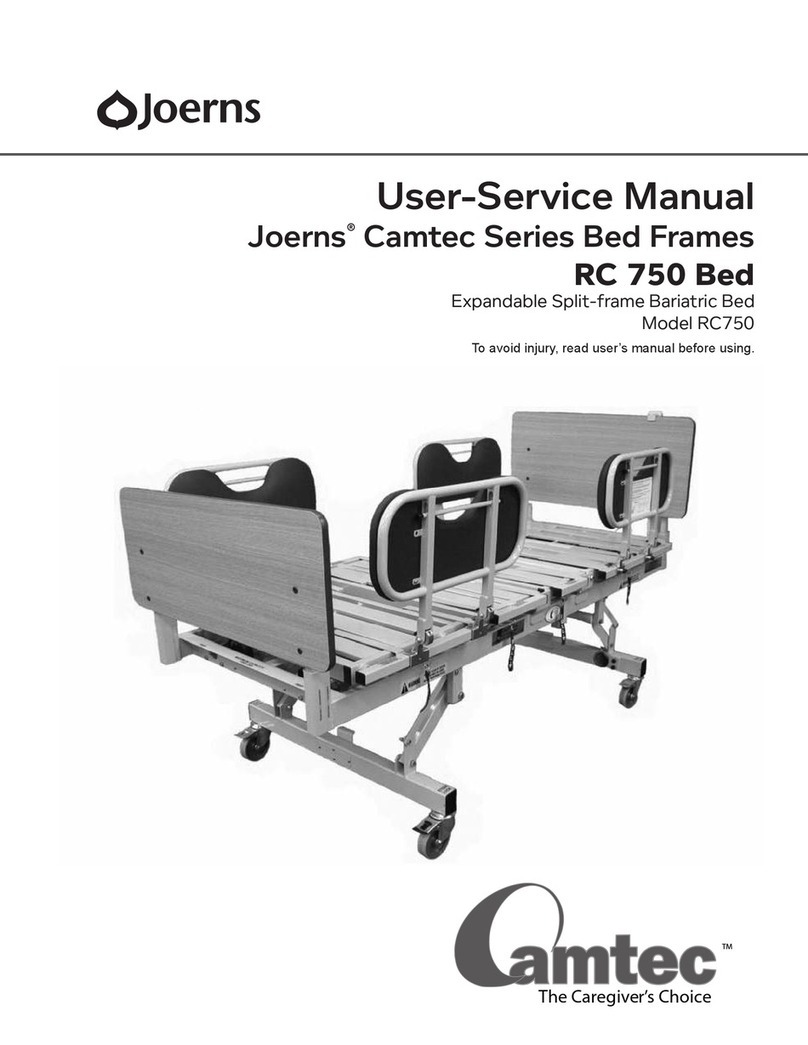

Joerns Camtec RC750 Troubleshooting guide

Joerns

Joerns Oxford User manual

Joerns

Joerns Oxford 0Y0050 Operator's manual

Joerns

Joerns Oxford In-Situ Operator's manual

Joerns

Joerns Bari10A Troubleshooting guide

Joerns

Joerns WeCare Troubleshooting guide

Joerns

Joerns Oxford Stretcher Adjustment Cradle Operator's manual

Joerns

Joerns WeCare Bed Troubleshooting guide

Joerns

Joerns Hoyer Calibre Operator's manual

Joerns

Joerns Oxford Up Operator's manual

Joerns

Joerns Hoyer Operator's manual

Joerns

Joerns Hoyer HPL700 Guide

Joerns

Joerns Oxford Limb Lifter Operator's manual

Joerns

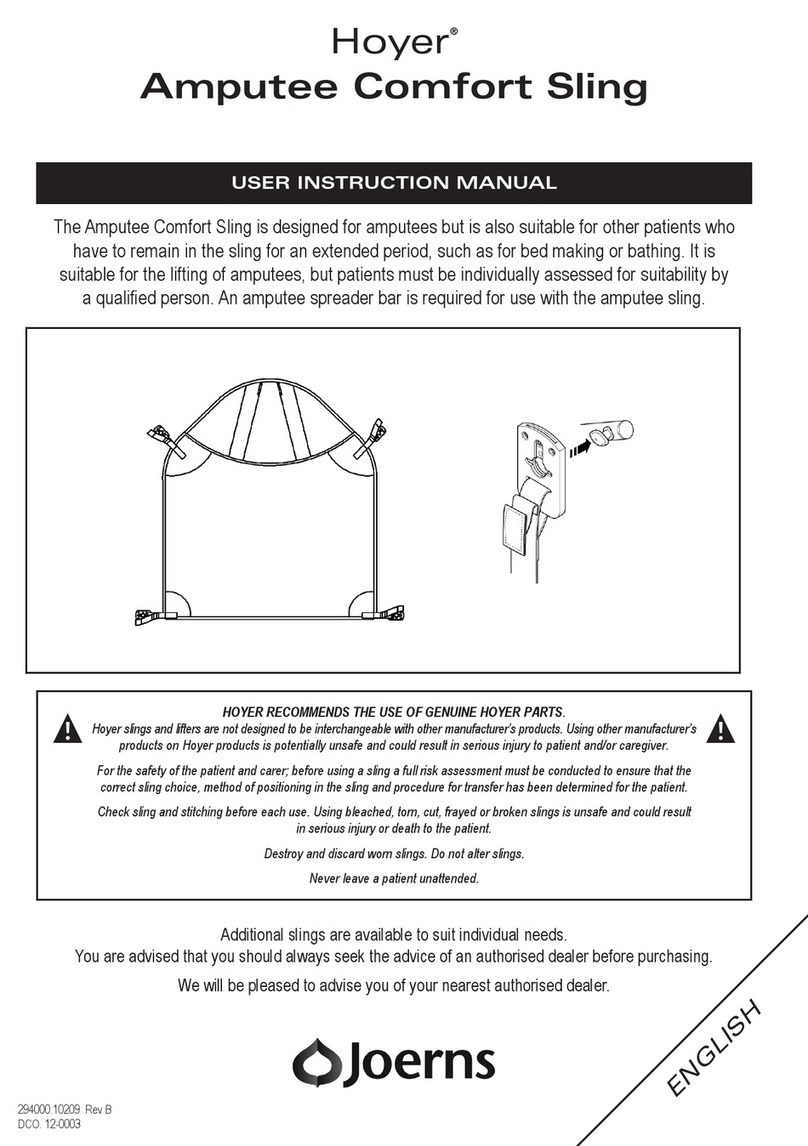

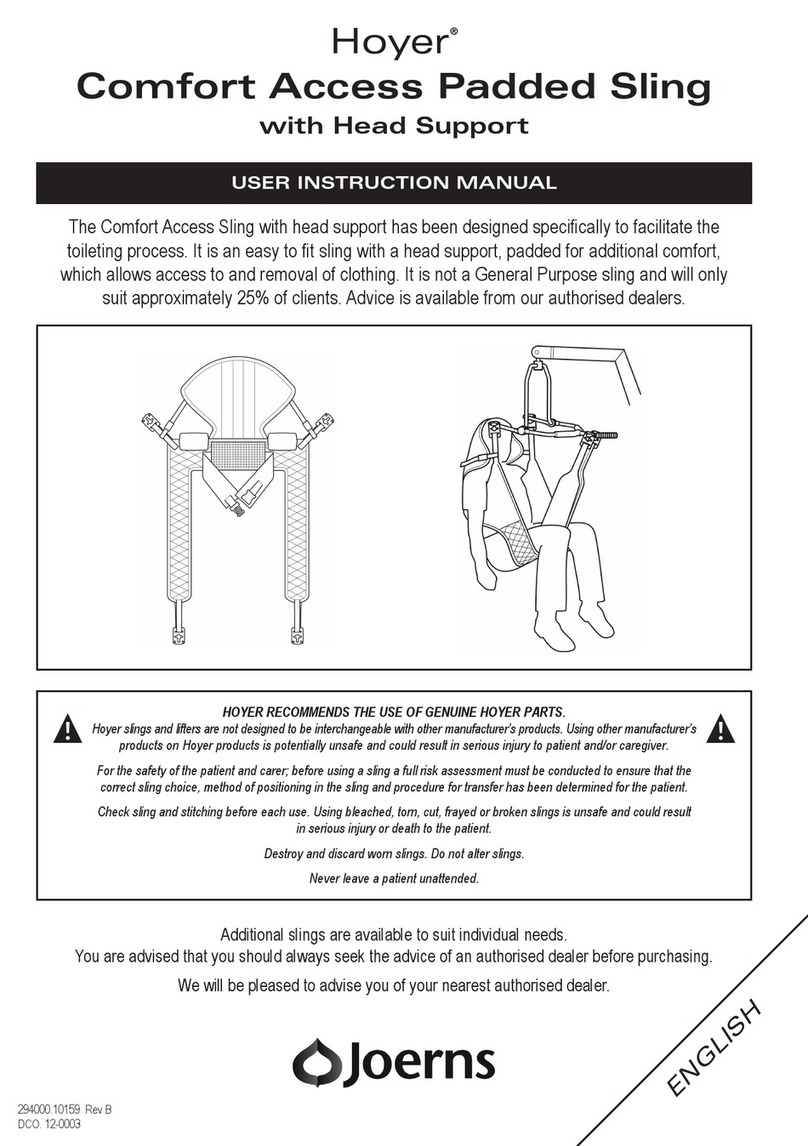

Joerns Hoyer Comfort Access Operator's manual