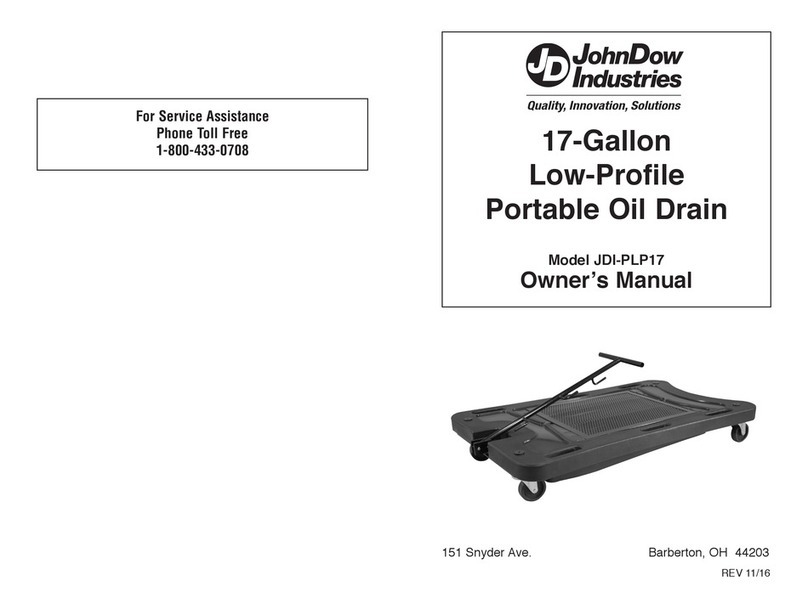

OPERATOR’S MAN AL JDI-LP5 OPERATOR’S MAN AL JDI-LP5

Operating and Safety Precautions:

1. Read assembly and operating instructions and instructions before use

2. Personnel should always wear proper personal protection equipment and clothing.

3. Ensure that all fittings and connections are properly tightened.

4. Oil is flammable. Keep away from heat, sparks, and open flames as an explosion will result in severe personal injury including death.

5. Monitor the fluid level when filling the drain to prevent overflow or spillage.

6. Use care when rolling the oil drain when it is full of oil to prevent splashing or spillage.

7. Periodically inspect the screen for debris that may prevent the flow of oil.

8. Always connect the evacuation hose before running pump

9. Monitor the discharge hose when evacuating the drain to prevent overflow or spillage

Product Specifications:

a. Max. Tank Capacity: 26.6 gal (100 L) c. Electrical: 120 V/ 50-60 Hz

b. Functional Capacity: 22.6 gal (85 L) d. Max. Flow Rate: 5 gpm (18.9 L/min)

Assembly

Tools and Supplies (not included)

PTFE tape 10 mm wrench 1-1⁄16” open end wrench 13mm open end wrench

11⁄16” open end wrench Pipe wrench Flat screw driver 17mm open end wrench

19mm open end wrench

Assembly Procedure:

1. Assemble M12 flat washer (15), nut (16), and hex head screw (14) to wheels (13) using

19mm socket and wrench (see Fig. 1).

2. Assemble four M10 hex head screws (9), four M10 nuts (12), and eight M10 flat washers

(10) per caster (11) using 17mm socket and wrench (see Fig. 2).

3. Wrap ¾ NPT threads on drain with PTFE tape and assemble ¾ NPT elbow (17). Tighten

using pipe wrench and position facing upward (see Fig. 3).

4. Remove eight M6 bolts (22) and pump cover (21) from rear of drain using 10mm wrench

(see Fig. 4). Mount the pump (23) and reinstall four M6 bolts with 10mm wrench.

5. Wrap ¾ NPT end of the ½ x 6-1/2 inch hose (18) with PTFE tape and thread into ¾ NPT

elbow(17). Tighten with a 1-1/16 inch wrench (see Fig. 5).

6. Wrap PTFE tape onto the ½ x 3/8 NPT hose barb fitting (20) and thread into the inside of

the pump (23). Tighten with a 11/16 wrench.

7. Place the hose clamp (19) on the ½ x 6-1/2 hose (18). Flex the hose to form a 90° arc and

slide the hose end onto the ½ x 3/8 hose barb fitting (20) on the pump (see Fig. 6).

8. Position the hose clamp and tighten with flat head screw driver.

9. Wrap PTFE tape onto ½ NPT thread end of the ½ x 5-1/2 inch outlet hose (24) and assem-

ble female quick connector fitting

10. Wrap PTFE tape onto the 3/8 NPT end of the ½ x 5-1/2 inch outlet hose (24) and thread into

pump (23). Tighten with 11/16 wrench (see Fig. 7).

11. Reinstall the pump cover (21) using four M6 bolts (22) and tighten with 10mm wrench (see

Fig. 8).

12. Wrap the electrical cord of pump on the cleat of pump cover.

13. Wrap PTFE on the ½ NPT thread of the ½ x 10’ evacuation hose and assemble to the male

quick connect fittings.

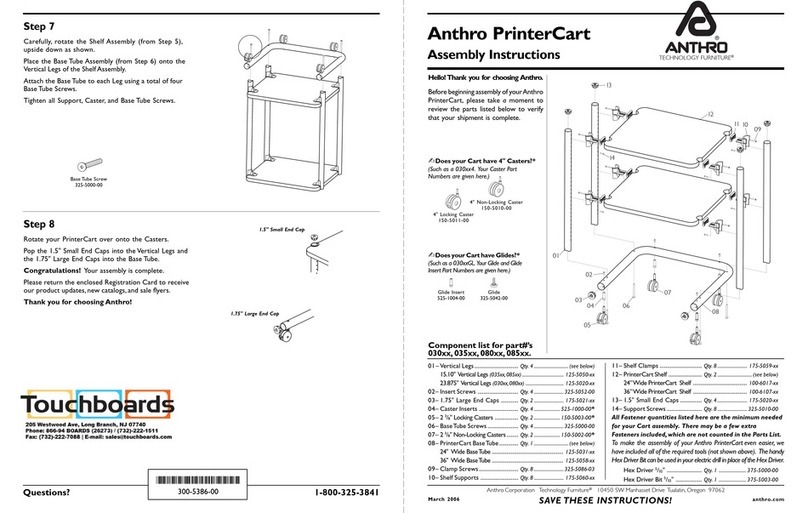

14. Assemble 4 piece handle assembly (3, 6 x2, 8) with four M8 washers (4), nuts (7), and hex

head screws (5), using 13mm socket and wrench (see Fig.9).

15. Attach handle assembly to tank with two M8 washers (4), nut (7), and hex head screw (5)

using 13mm socket and wrench

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 9

Fig. 7 Fig. 8

2. 3.

Product Specifications:

Contents:

Item

No. Description Qty.

12 M10 Nylon - Insert Locknut 8

13 6” Wheel 2

14 M12 Hex Head Cap Screw 2

15 M12 Flat Washer 2

16 M12 Nylon - Insert Locknut 2

17 3/4” NPT Elbow 1

18 1/2” x 5-1/2” Hose with 3/4”

Fitting 1

19 1” Hose Clamp 1

20 1/2” x 3/8” NPT Hose Barb

Fitting 1

Item

No. Description Qty.

1 Tank 1

2 Screen 1

3 Handle - Top 1

4 M8 Flat Washer 4

5 M8 Hex Head Cap Screw 2

6 Handle Brace 2

7 M8 Nylon - Insert Locknut 2

8 Handle Bottom 1

9 M10 Hex Head Cap Screw 8

10 M10 Flat Washer 16

11 Front Swivel Caster 2

Item

No. Description Qty.

21 Pump Cover 1

22 M6 Hex Head Cap Screw 8

23 120V Electric Pump 1

24 1/2” x 6-1/2” Outlet Hose with

3/8” and 1/2” NPT Fitting 1

25 1/2” NPT Female uick

Connector 1

26 1/2” NPT Male uick

Connector 1

27 1/2” x 10’ Evacation Hose 1