www.johnnyseeds.com27300.999Rev2.2‐3/23/15‐AL

Construction Options:

We provide instructions on two main methods to build your tunnel:

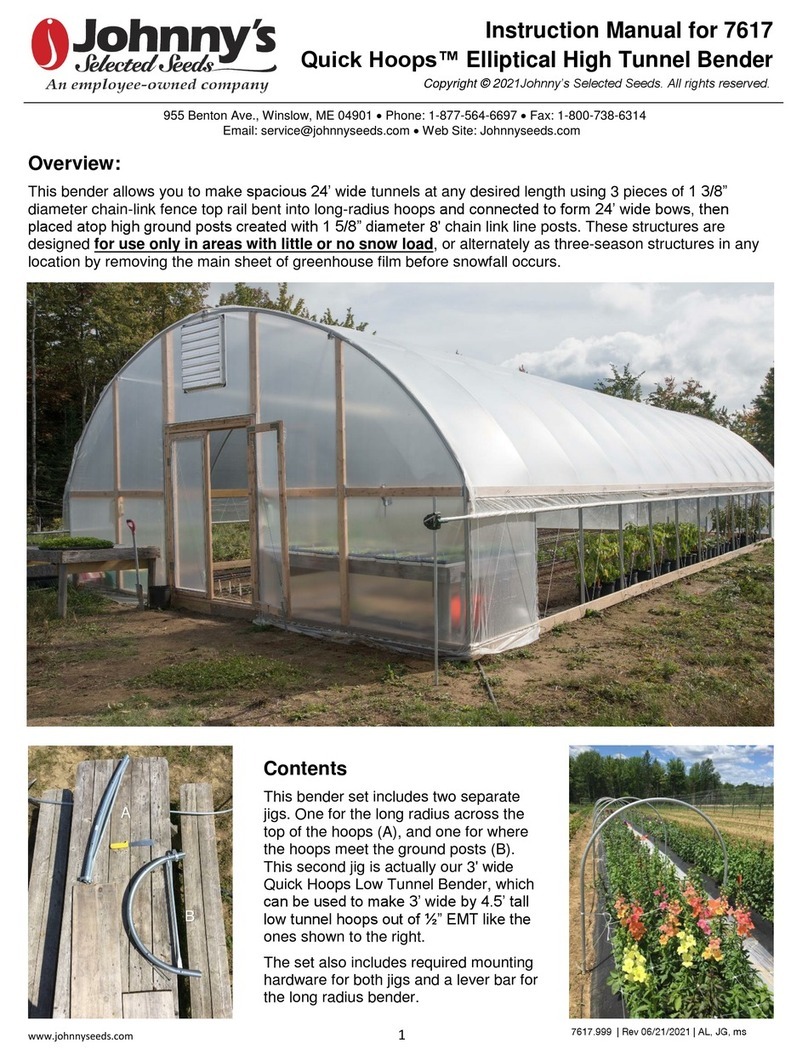

Eliot Coleman is credited for the conception of this hoop design as he incorporated it into the plans for his

modular moveable 'Cathedral' tunnel. His design criteria included requirements that the structure needed to

span four 30" beds, could shed snow easily, and could be moved in any direction. In the Fall of 2013, the

modular Cathedral tunnel was born. It was comprised of three 14' x 16' tunnel modules (the frame of one

module is shown above left) that are connected with a 1' space between to create a 50' structure. His idea was

that home gardeners could also build a single module for backyard use.

Johnny's has developed instructions using Eliot's hoop design, which we adapted to create traditional, fixed

high tunnels. This includes the use of more traditional elements, such as driven ground posts, framed end-

walls, hipboards, footboards, and roll-up side vents. This allows you to create a very solid, fixed structure with

a relatively small investment.

Eliot's original plans called for creating the side-hoops of the bows with the 9018 Quick Hoops™ High Tunnel

Bender and illustrated creating a jig to bend the 5 ft. peak section. Since then, Johnny's has developed the

7300 Quick Hoops™ Gothic High Tunnel Bender, which simplifies the process by including the 9018 Bender

plus a special jig for the peak sections. If you already own a 9018 Bender, you can choose to buy just the

7300.100 Peak Jig instead of the complete 7300 High Tunnel Bender. Both the 7300 and the 7300.100 will

include both sets of instructions so you can build either of these types of tunnels.

If you would like to build the Modular, Moveable 'Cathedral' tunnel, please refer to the other set of instructions.

The remainder of this set of instructions is written for the Traditional, Fixed 'Gothic' style tunnel.

14'x200'GothicTunnelatJohnny'sResearchFarm,Albion,ME

Modular, Moveable 'Cathedral' Tunnel Traditional, Fixed 'Gothic' Tunnel