TFP1586

Page 9 of 12

Care and

Maintenance

Inspection, testing, and maintenance

must be performed in accordance

with the requirements of the NFPA. Any

impairment must be immediately cor-

rected. See Table C for information on

troubleshooting valve problems.

The owner is responsible for the

inspection, testing, and maintenance

of their fire protection system and

devices in compliance with this doc-

ument, as well as with the applicable

standards of any authorities having

jurisdiction. Contact the installing con-

tractor or product manufacturer with

any questions.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualified Inspec-

tion Service in accordance with local

requirements and/or national codes.

Note: Before closing a fire protection

system maincontrol valve for maintenance

work on the fire protection system that

it controls, obtain permission to shut

down the affected fire protection systems

from the proper authorities and notify all

personnel who may be affected by this

decision.

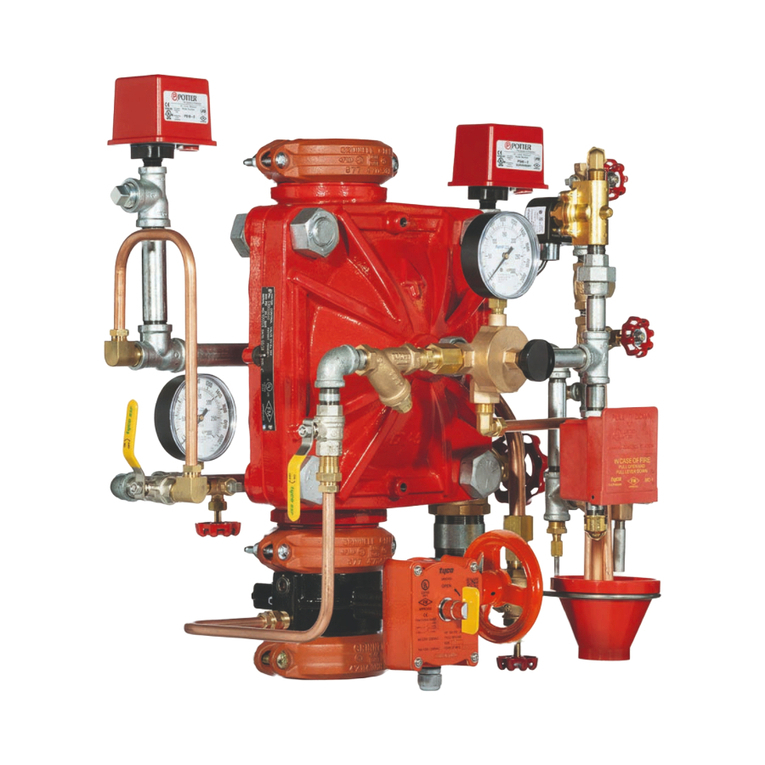

The TYCO Model RV-1aPressure Relief

Valve requires no lubrication, packing

or preventative maintenance. However,

replacement of the diaphragm every

ten years is recommended.

Inspections

• Inspect the Model RV-1aPressure

Relief Valve on a weekly basis.

• Check the valve under static condi-

tions to assure that the Model RV-1a

Pressure Relief Valve is not unnec-

essarily relieving pressure. If nec-

essary, re-adjust the Model RV-1a

Pressure Relief Valve by following the

instructions in the section Placing the

Valve in Service. If the desired pres-

sure cannot be achieved, the Dia-

phragm and/or Pilot Valve should be

replaced.

• During pump start-ups, check that

the Model RV-1aPressure Relief

Valve relieves pressure as nec-

essary. If necessary, re-adjust the

Model RV-1aPressure Relief Valve

by following the instructions in the

section Placing the Valve in Ser-

vice. If the desired pressure cannot

be achieved, the Diaphragm and/or

Pilot Valve should be replaced.

• Check that the Model RV-1aPres-

sure Relief Valve, Pilot Valve, Tube,

Fittings, and Pressure Gauge are in

good condition and do not exhibit

signs of damage or leakage.

• Make sure that the Pilot Valve Lock-

nut is securely tightened.

Diaphragm Replacement

Prior to replacing the Diaphragm, the

Model RV-1aPressure Relief Valve must

be taken out of service and completely

drained.

When reinstalling the Diaphragm Cover,

the Diaphragm Cover Fasteners must

be uniformly and securely tightened

using a cross-draw sequence. After

tightening, double check to make cer-

tain that all Diaphragm Cover fasteners

are securely tightened.

After cleaning and inspecting valve

interior, and replacing parts as nec-

essary, reinstall the Diaphragm Cover

by completing the following steps to

assure the Diaphragm Cover Fasteners

are uniformly and securely tightened.

Step 1. Ensure that the Diaphragm is

properly oriented and that the proper

hardware arrangement is utilized when

assembling the Diaphragm Covers. The

hardware arrangements differ depend-

ing on the size of the DV-5aValve.

Step 2. By first using the Long Hex

Bolts, support of the Diaphragm Cover

will be provided before installing the

Short Hex Bolts. Align Diaphragm in

proper orientation with Valve Body, and

then align Diaphragm Cover in proper

orientation with Valve Body. Hand-

tighten all fasteners.

Step 3. Using crossdraw sequence

to assure uniformity, wrench-tighten

Long Hex Bolts and Short Hex Bolts

to appropriate torque values. Repeat

crossdraw sequence two to three

times at incremental torque valves

until reaching the torque valves found

in Table B.

Step 4. Inspect to assure all Hex Bolts

are securely tightened.

Step 5. Using the union, secure the

RV-1Ato the Diaphragm cover.

Step 6. Using the union, secure the

RV-1Atrim.

Step 7. Ensure that the unions and

pipe nipples flare fittings are securely

tightened.

Pilot Valve Replacement

Prior to removing the Pilot Valve, the

Model RV-1aPressure Relief Valve must

be taken out of service and completely

drained.

When installing the replacement Pilot

Valve, the trim components must be

replaced exactly as they were. After

reinstalling the Pilot Valve and before

returning the Model RV-1aPressure

Relief Valve into service, completely

unscrew the Adjusting Screw. Then, to

place the Model RV-1aPressure Relief

Valve in service, follow the instruc-

tions in the section Placing the Valve

in Service.

NOTICE

The Pilot Valve is not field repairable.

Attempting to repair the Pilot Valve may

render the valve ineffective and impair

the system operation.

Completely unscrewing the Adjusting

Screw of the replacement Pilot Valve

will help to avoid an accidental over-

pressurization of the system piping

prior to achieving the desired relief “set

pressure”.

Nominal

Valve Sizes

ANSI

Inches

(DN)

Torque

lb-ft

(N∙m)

Nuts Short

Hex

Bolts

2

(50)

44

(59,7)

35

(47,5 )

3

(80)

188

(254,9)

150

(203,4)

4

(100)

396

(536,9)

316

(428,4)

6

(150)

265

(359,3)

212

(287,4)

8

(200)

545

(738,9)

436

(591,1)

TABLE B

DIAPHRAGM COVER BOLTS

MINIMUM TORQUE