Johnson Controls EDA-8102 Assembly instructions

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls P77 Series User manual

Johnson Controls

Johnson Controls M9132-AG -1N Series User manual

Johnson Controls

Johnson Controls TEC3010 User manual

Johnson Controls

Johnson Controls LX-HPUL-1 User manual

Johnson Controls

Johnson Controls FX80 User manual

Johnson Controls

Johnson Controls Hitachi C4IRK01 User manual

Johnson Controls

Johnson Controls VMA1615 User manual

Johnson Controls

Johnson Controls TEC3010 User manual

Johnson Controls

Johnson Controls M9316-A Z Series User manual

Johnson Controls

Johnson Controls PCV1617 User manual

Johnson Controls

Johnson Controls RA-3 Series Owner's manual

Johnson Controls

Johnson Controls Metasys VMA1610 User manual

Johnson Controls

Johnson Controls tyco Kantech IP LINK User manual

Johnson Controls

Johnson Controls EDA-8102 User manual

Johnson Controls

Johnson Controls Joventa BAS1(S) User manual

Johnson Controls

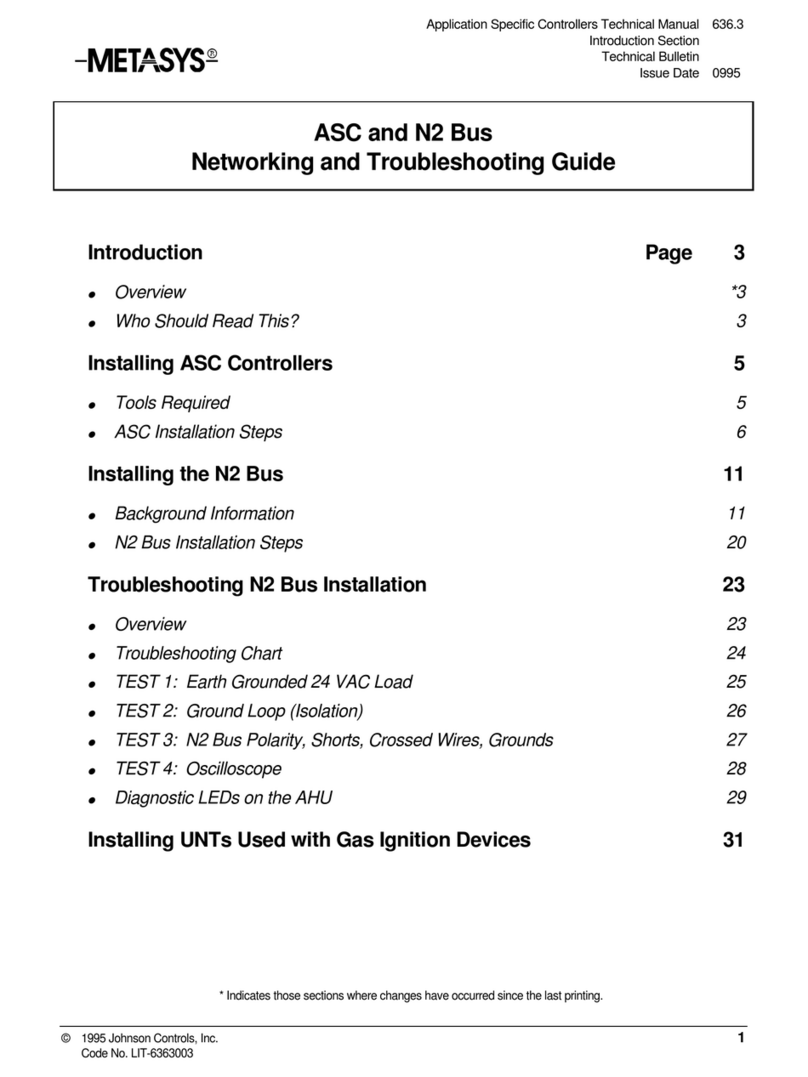

Johnson Controls METASYS ASC User manual

Johnson Controls

Johnson Controls F4-SNC User manual

Johnson Controls

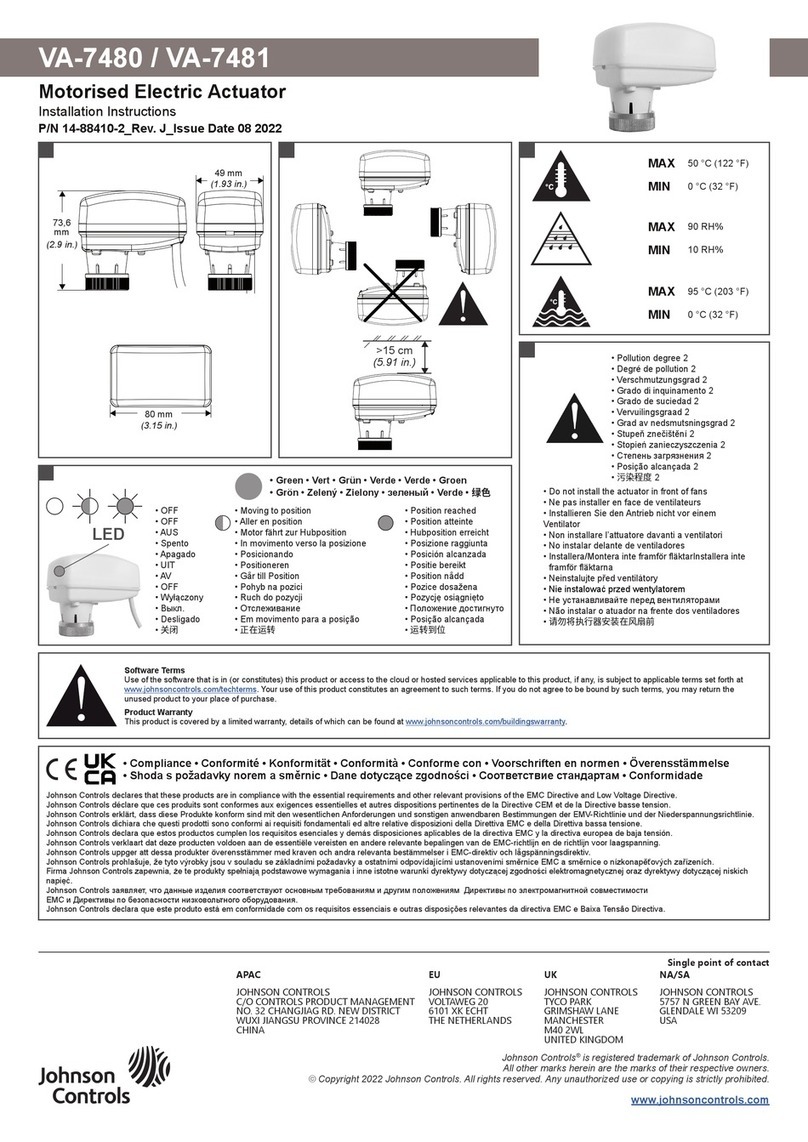

Johnson Controls VA-7480 User manual

Johnson Controls

Johnson Controls FX-PCV1656 User manual

Johnson Controls

Johnson Controls tyco Power Pro Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions