M9200 Series Electric Spring Return Actuator Product/Technical Bulletin 5

7. Keeping the actuator flat, evenly hand tighten each

clamp nut onto the U-bolt. Use a 10 mm nut driver

or adjustable wrench to finish securing the U-bolt

to the damper shaft.

8. Turn the manual crank CW to release the spring,

and remove the manual crank. (The actuator will

spring return to its starting position.)

9. Verify that the actuator rotates freely throughout

the range. (This can be done by applying a full

stroke control signal or reinserting the manual

crank and turning it CW to rotate the coupler to the

fully open position.)

R

otation Range

The actuator is factory set for 0 to 93° rotation. The

rotation range is changed by repositioning the coupler

and adjusting the rotation limiters. This can be done by

using an input signal or the manual crank.

To change the rotation range using the manual crank:

1. Push the manual crank into the manual override

gear firmly, and wind in a CW direction until the

position indicator reaches the 45° position.

IMPORTANT: Turn the manual crank in a

CW direction only, unless locking a

new position.

2. Lock this position by winding the manual crank

1/4 turn CCW or until a slight resistance is felt.

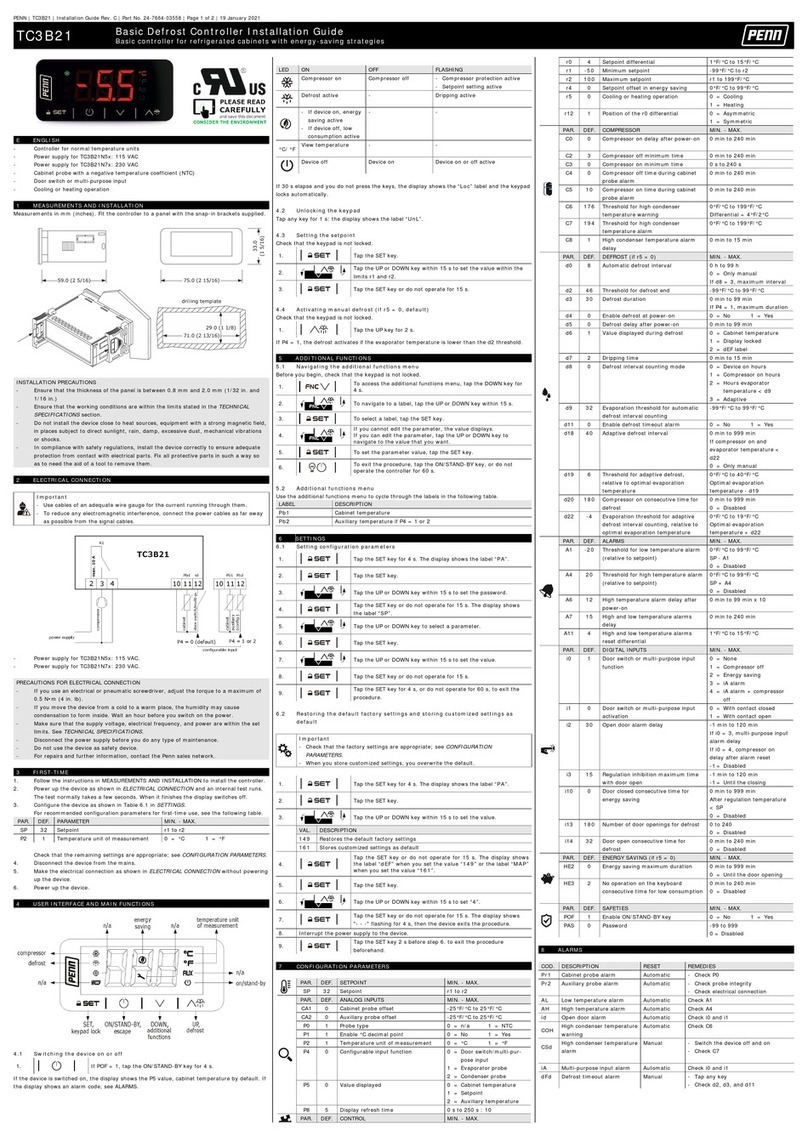

3. Use a 7 mm nut driver to loosen the screws on the

rotation limiter. (See Figure 7.)

Note: Rotation limiters are shown

factory set in the fully down

position for 90° rotation.

0

30

60

90

0

30

Limit Stop

Screws

(2 on Each

Limiter)

Rotation

Limiters (2)

0

10

30

20

(Increments

correspond

to those on

the opposite

side.)

Figure 7: Rotation Limiters

4. Slide the rotation limiter to the desired position,

and retighten the screws to a maximum of

30 lb·in (3.4 N·m).

Examples of rotation limiter adjustments:

For a range of 30°, adjust both limiters fully up.

•To set a rotation range of 45°, adjust

one rotation limiter to 30° and the other to 15°.

•To set a range of 60°, adjust one limiter to 30°,

and leave the other at 0°.

5. Reinsert the manual crank into the manual

override gear.

6. Repeat Steps 2 through 5 to set the rotation range

for the second rotation limiter.

7. Release the manual crank spring lock by winding it

1/4 turn in a CW direction.

8. Remove the manual crank, and return it to its

original position on the actuator cover.

Note: When changing the rotation range on models

with auxiliary switches, one or both switches

may need to be adjusted. (See

Auxiliary

Switches

section.)

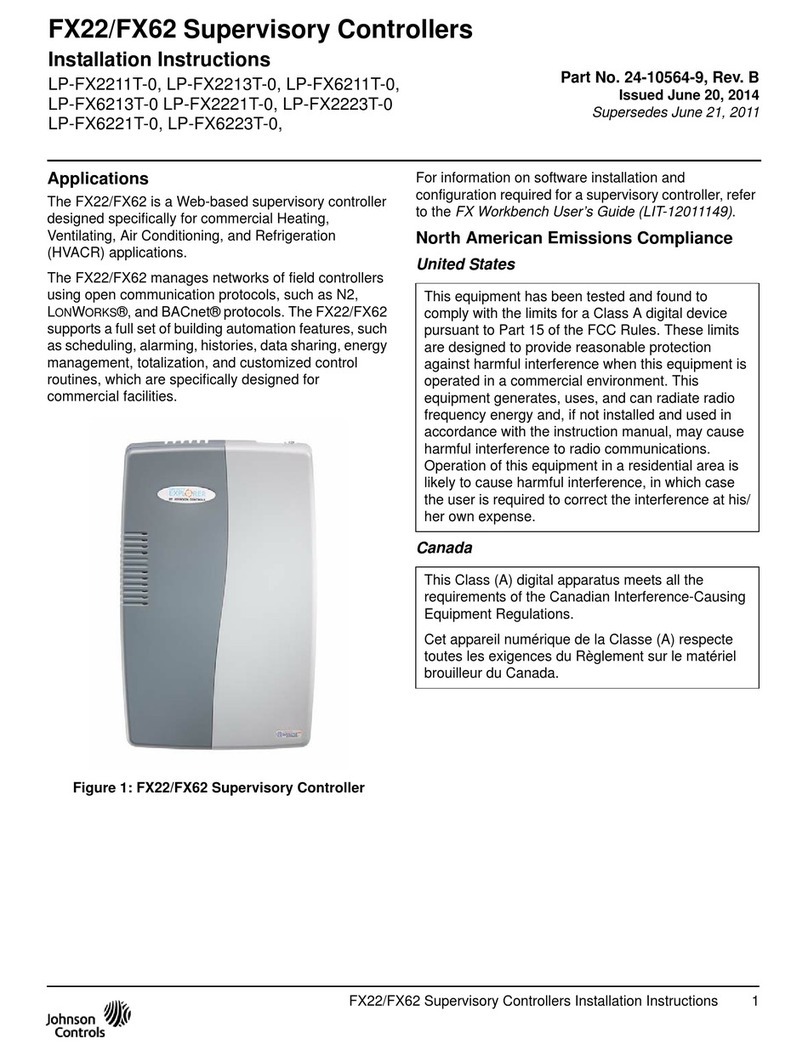

Feedback Signal

The feedback signal will vary with a change to the

rotation range. The resistance feedback is reduced

corresponding to the reduced rotation range for the

AGD and AGE models.

For the HGA, HGC, JGA, and JGC models, a change

to the rotation range changes the feedback signal and

the operating range proportionally. (See Figure 8.)

90°

90°

0.0V

2.0V

10.0V

8.7V 7.3V 6.0V 4.7V 3.3V

10.0V

8.3V 6.7V 5.0V 3.3V 1.7V

75°

75°

60° 60°45°

45° 30°

30°

15°

15°

0°

0°

Rotation Range

2-10V

Feedback

0-10V

Feedback

Direct

Acting

1000

Ω

135

Ω

113

Ω

667

Ω

90

Ω

45

Ω

167

Ω

Ω

Ω

0

0

833

Ω

68

Ω

23

Ω

0-135 ohms

Feedback

0-1000 ohms

Feedback

Ω

500 333

Ω

Direct or

Reverse

Acting

2-10V

Feedback

Reverse

Acting

0-10V

Feedback 0.0V 1.7V 3.3V 5.0V 6.7V 8.3V 10.0V

10.0V8.7V

7.3V

6.0V4.7V

3.3V

2.0V

Rotation Limiter

Adjustment

Rotation Limiter

Adjustment

Note: 0-135 ohms feedback is available on AGD models and

0-1000 ohms feedback on AGE models.

0-10V or 2-10V is available on HGA, HGC, JGA, JGC models.

Figure 8: Nominal Feedback Signal Relative to

Rotation Range