Johnson Controls A19ZBA User manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls SE-SPU101 Series User manual

Johnson Controls

Johnson Controls CK721-A User manual

Johnson Controls

Johnson Controls VA7820-GG-1 Series User manual

Johnson Controls

Johnson Controls M9220-Bxx-3 User manual

Johnson Controls

Johnson Controls FMS-2000C User manual

Johnson Controls

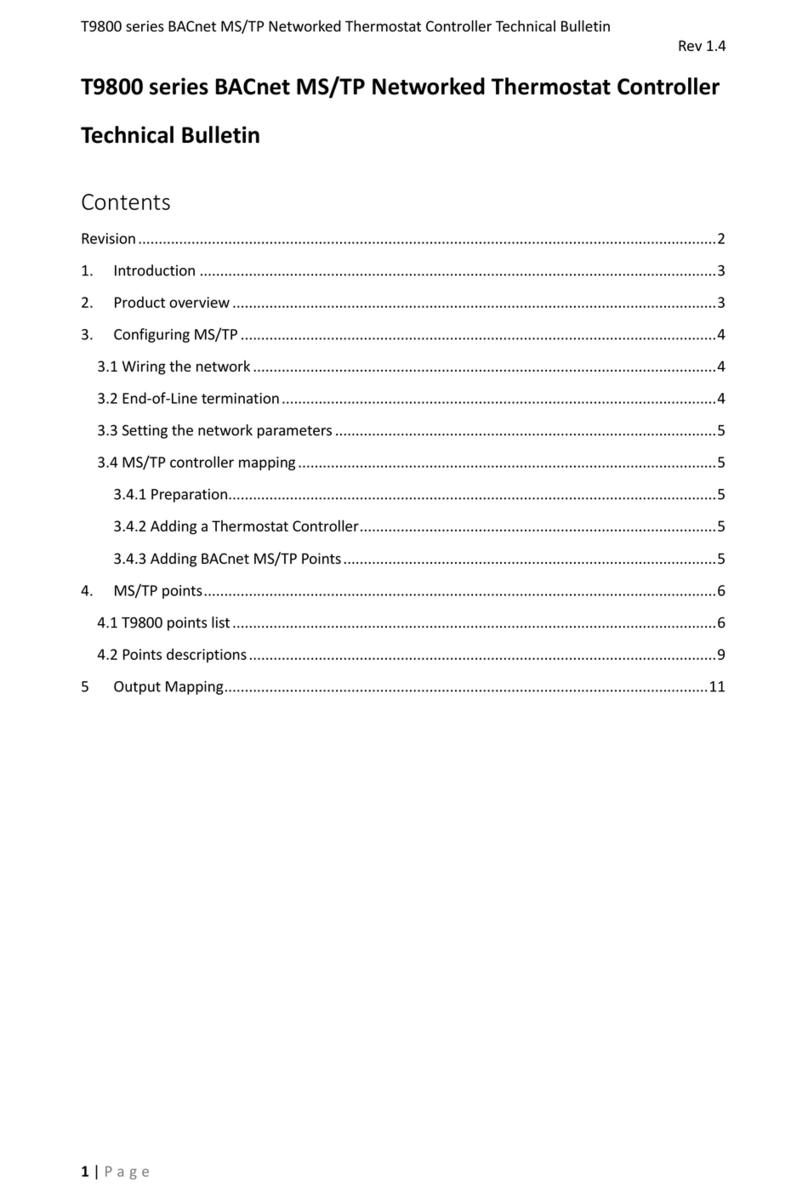

Johnson Controls T9800 Series Service manual

Johnson Controls

Johnson Controls F4-CG Series User manual

Johnson Controls

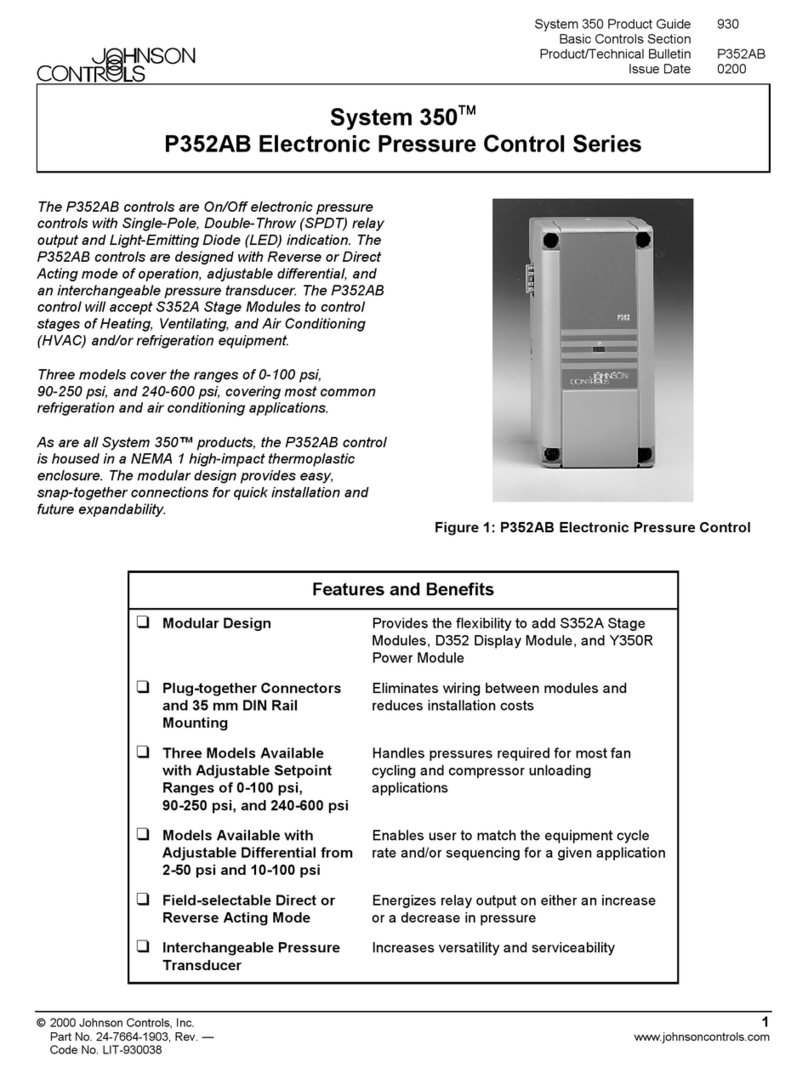

Johnson Controls System 350 P352AB Series User manual

Johnson Controls

Johnson Controls M100G User manual

Johnson Controls

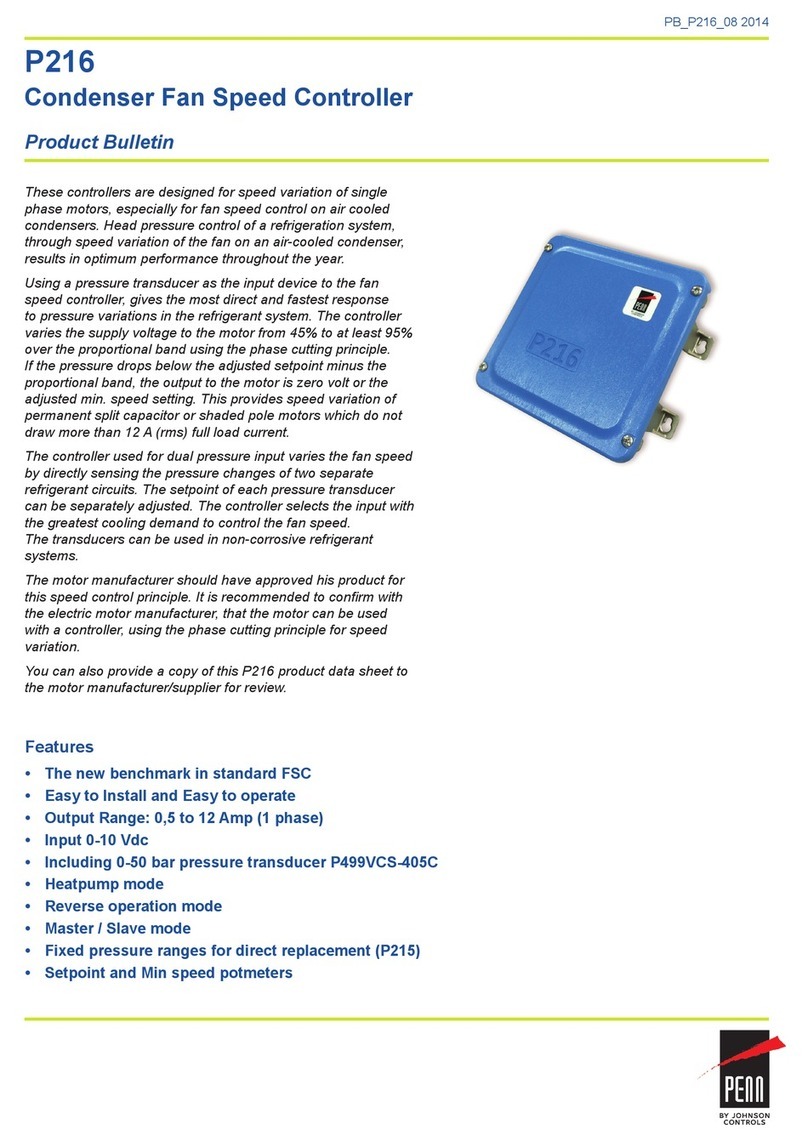

Johnson Controls Penn P216 User manual

Johnson Controls

Johnson Controls CK721-A Quick start guide

Johnson Controls

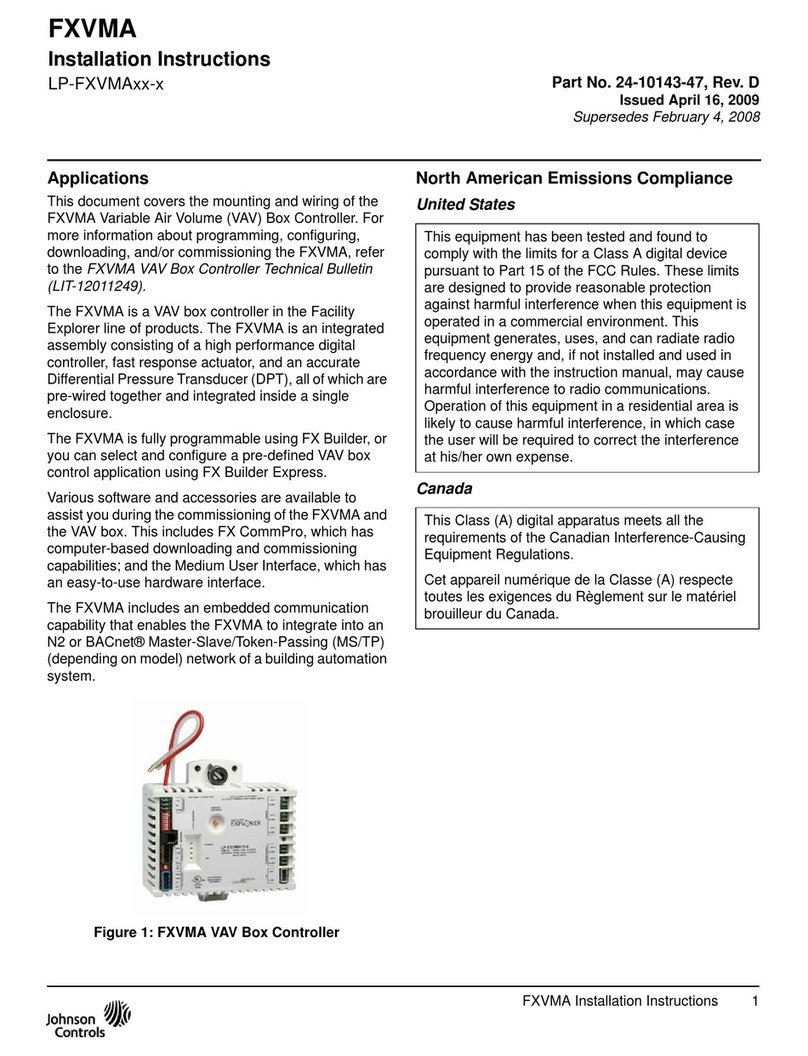

Johnson Controls LP-FXVMA Series User manual

Johnson Controls

Johnson Controls M9310-HGA-3 User manual

Johnson Controls

Johnson Controls FX-PCV1930 User manual

Johnson Controls

Johnson Controls VG1600 Series User manual

Johnson Controls

Johnson Controls FAC2513 User manual

Johnson Controls

Johnson Controls Hitachi C4IRK01 User manual

Johnson Controls

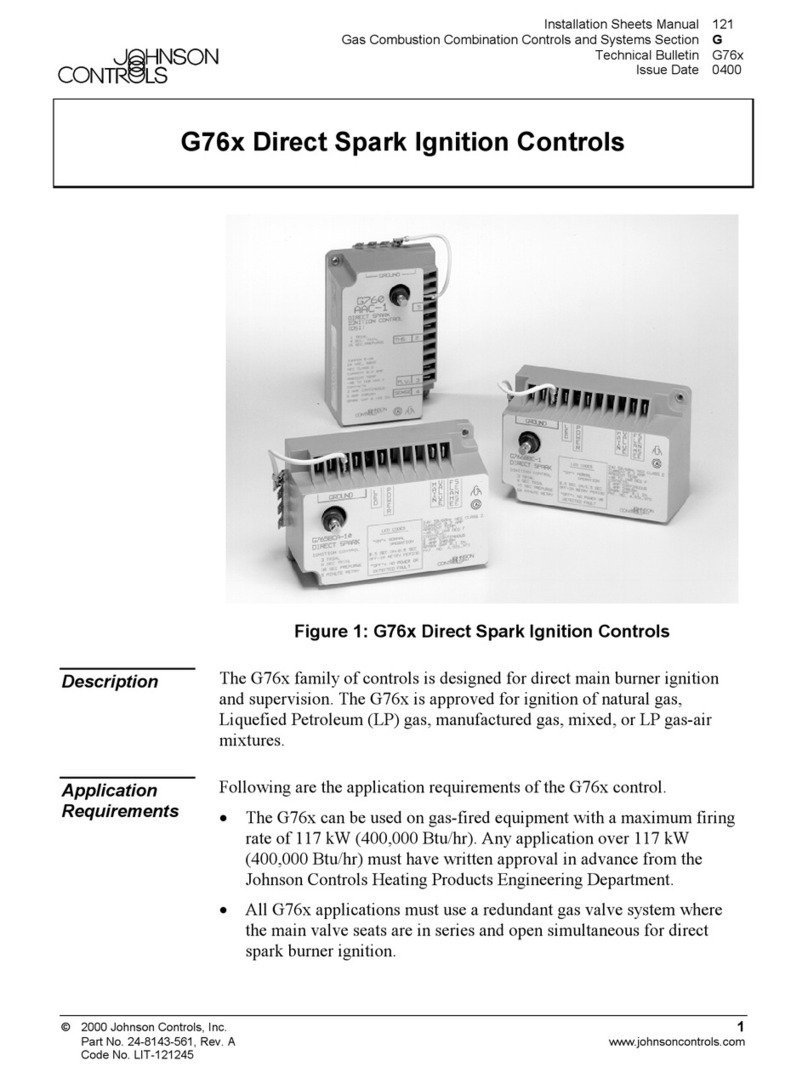

Johnson Controls G76 Series User manual

Johnson Controls

Johnson Controls PENN P70 Series User manual

Johnson Controls

Johnson Controls NAE Instruction Manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions