Controls Group 507 E. Michigan Street

P.O. Box 423, Milwaukee, WI 53202

Code No. LIT-1900119

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson

Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.© 10/01 Johnson Controls, Inc

1/2

m910-26 1900119 9thcc:na Electronics Actuators Rev:

021201

logo:

left ft:

right ft:

standard

Sect# = 0

seQ# = 106

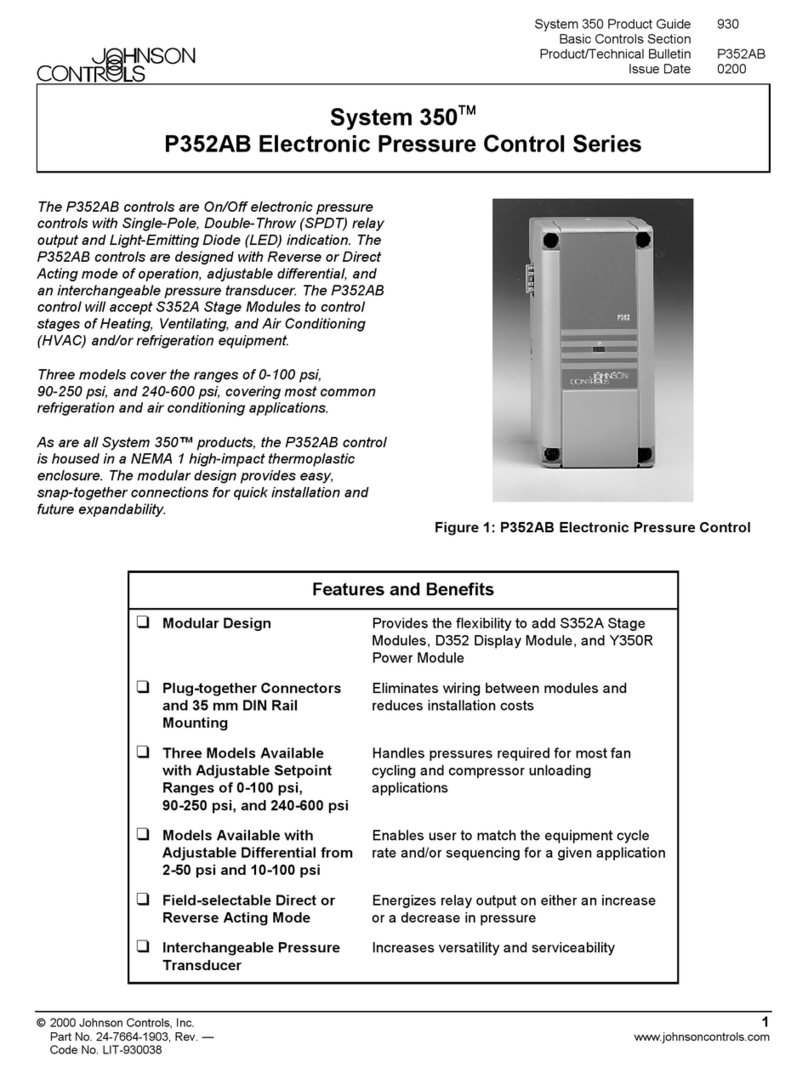

M9106-AGx-2N0x Series

Electric Non-spring Return Actuators

m9106-2n.tif

M9106-AGS-2N02

Description

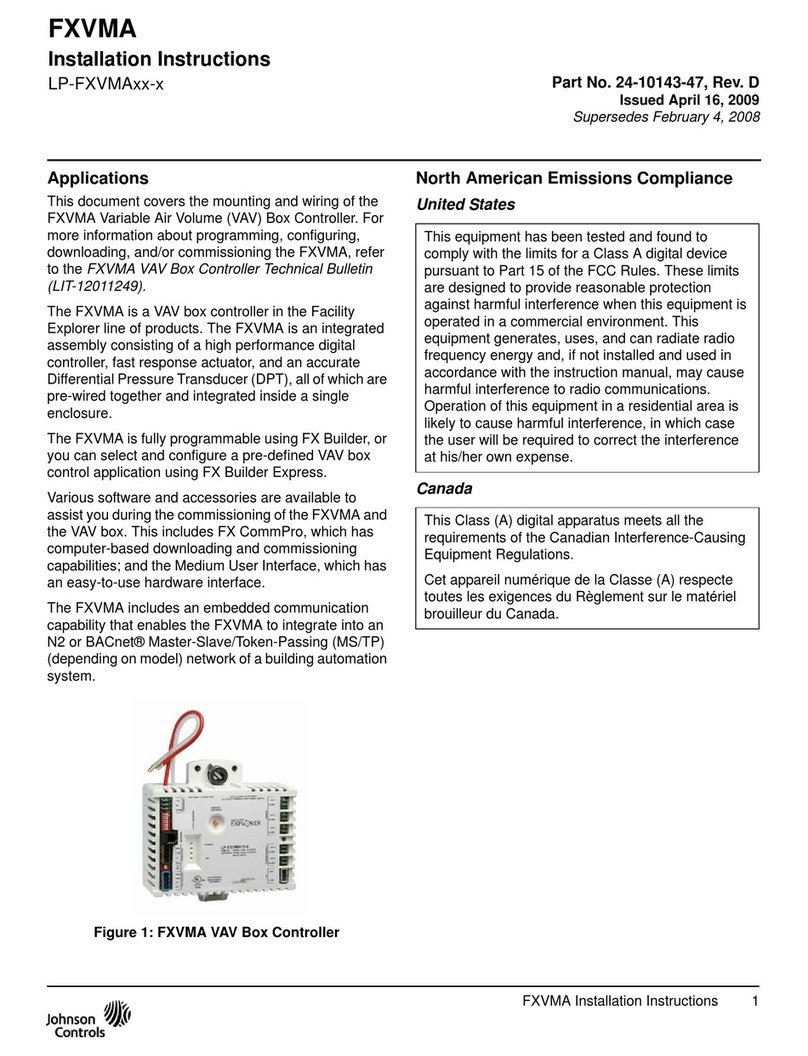

The M9106-AGA-2N0x synchronous

motor-driven actuators provide floating

(3-wire) control and are easily installed on a

Variable Air Volume (VAV) box. They may

also be installed on a small or medium-sized

damper with a round shaft up to 1/2 inch

(13 mm) in diameter or a 3/8 inch (10 mm)

square shaft.

These compact, non-spring return actuators

have 53 lb·in (6 N·m) running torque in a

compact easy-to-install package. The

actuators are available with either a nominal

60-second travel time at 60 Hz (72 seconds at

50 Hz) or a nominal 120-second travel time at

60 Hz (144 seconds at 50 Hz) for 90° of

rotation.

The M9106-AGS-2N02 Actuator/Transmitter

combines an M9106-AGA-2N02 with a

prewired DPT-2015 Differential Pressure

Transmitter that has a 0 to 1.5 in. W.C.

(0 to 374 Pa) differential pressure range.

Features

• 35 dBA rating meets audible requirements

for open ceilings

• synchronous drive provides constant

rotation time that is independent of load

• direct shaft mount with single-screw

coupler simplifies installation and provides

3-point shaft gripping

• magnetic clutch provides torque protection

for the actuator and damper

• adjustable rotation stops allow application

versatility with 30 to 90° clockwise or

counterclockwise rotation

• manual gear release simplifies setup and

field adjustments

• screw terminal connection makes wiring

easy

Applications

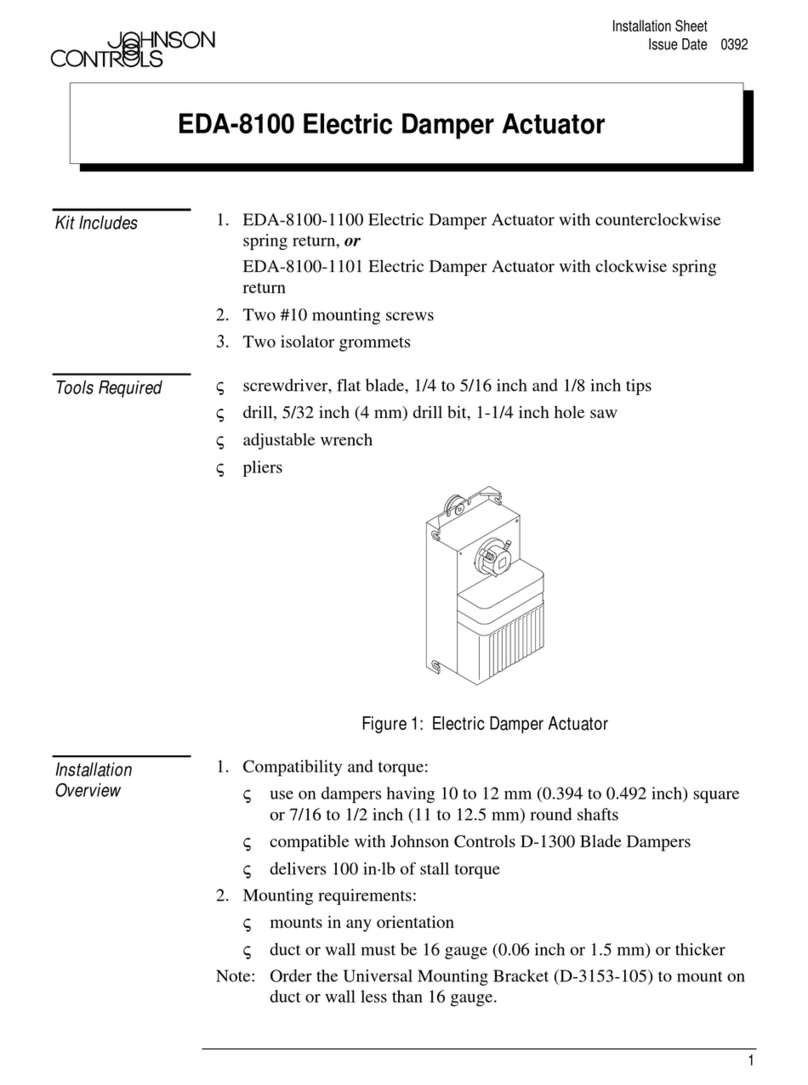

The actuators are used to position balancing,

control, round, and zone dampers in typical

HVAC applications. They are also used to

position the blades in a VAV box. The

actuators mount directly to the surface of a

VAV box, round damper, or small rectangular

damper with a single No. 10 self-drilling sheet

metal screw (included). There are no

additional linkages or couplers required.

Clearly labeled electrical terminals simplify

installation. Refer to the damper or VAV box

manufacturer’s information to select the

proper timing for the actuator.

Note: The damper rotation time must be

defined at the controller, and the

damper point definition must match

the rotation time of the actuator.

When combined with a VAV controller, the

actuator provides reliable integrated damper

control. See the M9106-AGx-2N0x Series

Electric Non-spring Return Actuators

Application Note, LIT-2681116 for various

configurations with and without the DPT-2015

differential pressure transmitter.

For more information, refer to the

M9106-AGx-2N0x Electric Non-spring Return

Actuators Product Bulletin, LIT-2681126 or

the M9106-AGx-2N0x Electric Non-spring

Return Actuators Installation Instructions,

Part No. 34-636-1077.

Repair Parts

Replace the unit.

To Order

Specify the code number from the

selection chart.

Selection Chart

Code Number Description

M9106-AGA-2N01 Electric actuator with 1 min.

rotation time

M9106-AGA-2N02 Electric actuator with 2 min.

rotation time

M9106-AGS-2N02 Electric actuator with 2 min.

rotation time includes the

DPT-2015 and CBL-2000-1

Accessories

Code Number Description

CBL-2000-1 20 in. (0.5 m) wiring harness, UL accepted for plenum use, supplied with the

M9106-AGS-2N02 and may be ordered separately; connects the M9106 and

DPT-2015 to the VAV controller

CBL-2000-2 20 in. (0.5 m) plenum-rated wiring harness

CBL-2000-3 72 in. (1.8 m) plenum-rated wiring harness

DPT-2015-0 0 to 1.5 in. W.C. (0 to 375 Pa) differential pressure transmitter supplied with the

M9106-AGS-2N02 and may be ordered separately

DMPR-KC003 Blade Pin Extension without bracket supplied with Johnson Controls

CD-1300 dampers and may be ordered separately

DMPR-KR003 Sleeve Pin Kit supplied with Johnson Controls round dampers that have a 5/16 in.

(8 mm) shaft and may be ordered separately

DMPR-KC010 (a)

(a) Use with an M9106 actuator to replace an EDA-2040 or ATP-2040 actuator and

EDA-2040-102 switch kit.

Adjustable Blade Position Indicator Switch Kit with total switching load limited to

2000 VA for the following applications:

Pilot Duty: 24 VAC, 50 VA; 125/250/277 VAC, 125 VA

Motor Load: 125/250/277 VAC, 1/3 hp

Resistive Load: 125 VAC, 11 A; 250 VAC, 8 A; 277 VAC, 7 A

(all maximum values)

M9000-200 Commissioning Tool provides a control signal to drive on/off, floating,

proportional, or resistive actuators.