TFP1262

Page 2 of 4

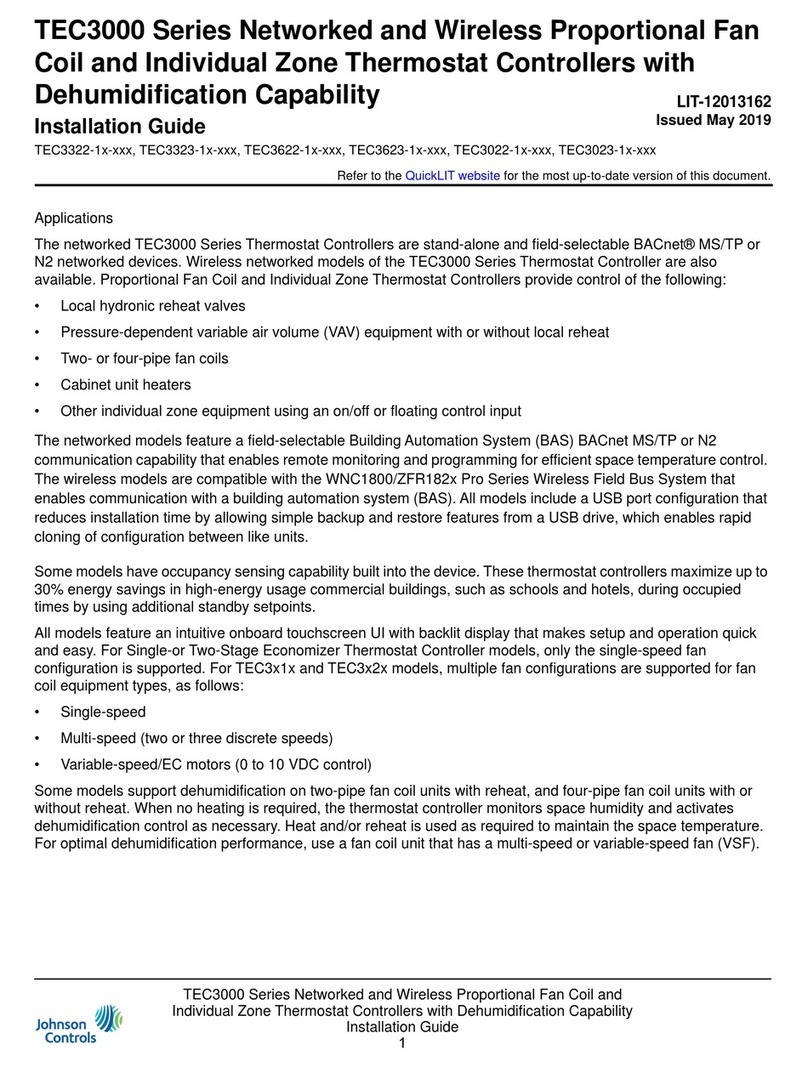

FIGURE 1

MODEL TAV-D AIR VENT DRY

AS S EM BLY

Operation

Step 1. Verify the vent assembly is

equipped with a restricted venting

orifice downstream of the backpres-

sure regulator.

Note: If the vent assembly is not equipped

with a restricted venting orifice, one will be

provided by TYCO during system commis-

sioning. The restricted venting orifice must

be installed before proceeding with the

steps below.

Step 2. Determine the low air alarm

pressure and the turn-on pressure of

the nitrogen generator.

Step 3. Choose a pressure setting

for the backpressure regulator that

is 3 to 5 psig (0,2 to 0,3 bar) above

the low air alarm pressure but below

the turn-on pressure of the nitrogen

generator.

Step 4. Pull the knob out from the reg-

ulator to adjust the pressure setting.

Turn the knob clockwise to raise the

pressure, counter-clockwise to lower

the pressure.

Step 5. Close the ball valve and allow

the device to depressurize through

the restricted venting orifice to the

pressure setting. Adjust the pressure

setting using the knob, then open the

ball valve to pressurize the device and

close the ball valve again to check the

pressure setting. Repeat the process

until the desired pressure setting is

achieved.

Note: This process can only be performed

when the fire sprinkler system is at normal

operating pressure.

Step 6. Push the knob back into the

regulator until it clicks into place.

Step 7. Once the TYCO Nitrogen Gen-

erator is commissioned, open the iso-

lation ball valve on the vent assembly.

The Air Vent is now open and actively

venting oxygen from the fire sprin-

kler system. It should remain open

for approximately 14 days or until the

system nitrogen concentration reaches

98% or greater. Use a TYCO Model

THGA Handheld Gas Analyzer to verify

the gas concentration inside the fire

sprinkler system.

Step 8. Close the isolation ball valve.

Failure to close the manual ball valve

after 14 days or once the fire sprinkler

system nitrogen concentration reaches

98% will result in additional oxygen

corrosion damage to the system and

unnecessary run time of the air com-

pressor and nitrogen generator.

Step 9. If the sprinkler system actuates

or another event introduces oxygen

to the sprinkler system the manual

ball valve must be opened again for a

period of 14 days to vent oxygen from

the system.

Installation

The TYCO Model TAV-D Air Vent, Dry

must be installed in accordance with

this section.

Step 1. The Model TAV-D Air Vent is

equipped with a ball valve to be con-

nected to the fire sprinkler riser. The

contractor must install a 1 in. outlet

(welded or mechanical) to connect the

vent assembly to the sprinkler system

on the system side of the main control

valve as shown in Figure 2. The ball

valve must remain in the closed posi-

tion until the TYCO Nitrogen Generator

is commissioned.

Step 2. Install the vent assem-

bly in a level position. The recom-

mended mounting height is between

5 ft to 10 ft (2 m to 3 m) above the fin-

ished floor.

Note: Piping to the vent assembly cannot be

installed in a configuration that would trap

water and prevent drainage to the sprinkler

system; a water trap impedes the ability of

the vent assembly to vent oxygen from the

fire sprinkler system.

Step 3. Inspection of the vent assem-

bly should be performed after installa-

tion and hydrostatic testing of the fire

sprinkler system. Inspection should

be performed periodically thereaf-

ter in accordance with the applicable

NATIONAL FIRE PROTECTION ASSO-

CIATION (NFPA) codes and standards

and/or the authority having jurisdiction.

Note: Inspection must include the condition

of the in-line filter and checking for blockage

in the “Y” strainer and the restricted venting

orifice.

RESTRICTED VENTING ORIFICEIN-LINE FILTER

MUFFLER

GAS SAMPLE PORT

BACKPRESSURE REGULATOR

CONNECTION TO

SPRINKLER SYSTEM

ISOLATION

BALL VALVE

QUICK CONNECT

“Y” STRAINER

WITH BALL VALVE

FLOAT

VALVE