Figure 5: Reinstalling the cover

4. Reinstall the cover and tighten the screws with a

Phillips screwdriver. See Figure 5.

Wiring

About this task:

This device has a half-wave type power supply so use

caution when you wire multiple devices. Ensure that the

circuit ground point is the same on all devices and on the

controller. This device is reverse voltage-protected and will

not operate if you connect the power supply backwards.

Important: Use 22 AWG shielded wire for all

connections and do not locate the device wires in the

same conduit as wires that supply inductive loads

such as motors. Disconnect the power supply before

you make any connections to prevent electrical shock

or equipment damage. Make all connections in

accordance with national and local codes.

Note: If you install the device at either end of the

network, install an end-of-line (EOL) termination

resistor (121 ohm) in parallel to the A (-) and B (+)

terminals. This device includes a network termination

jumper that connects the resistor correctly on the

Printed Circuit Board (PCB). Simply move the PCB

jumper to the EOL position and you do not require

an external resistor. Connect the ground wire of

the shielded pair to earth ground at the end of the

network, the master wire is not grounded. Do not

run bus wiring in the same conduit as line voltage

wiring.

Note: A network segment is a single-shielded wire

loop run between several devices (nodes) in a daisy

chain configuration. The total segment length should

be less than 4000 ft (1220 m) and the maximum

number of nodes on one segment is 255 for Modbus.

Nodes are any device that you connect to the loop

and include controllers, repeaters, and sensors

such as the CO sensor but does not include the EOL

terminators.

To wire the transmitter, complete the following

steps:

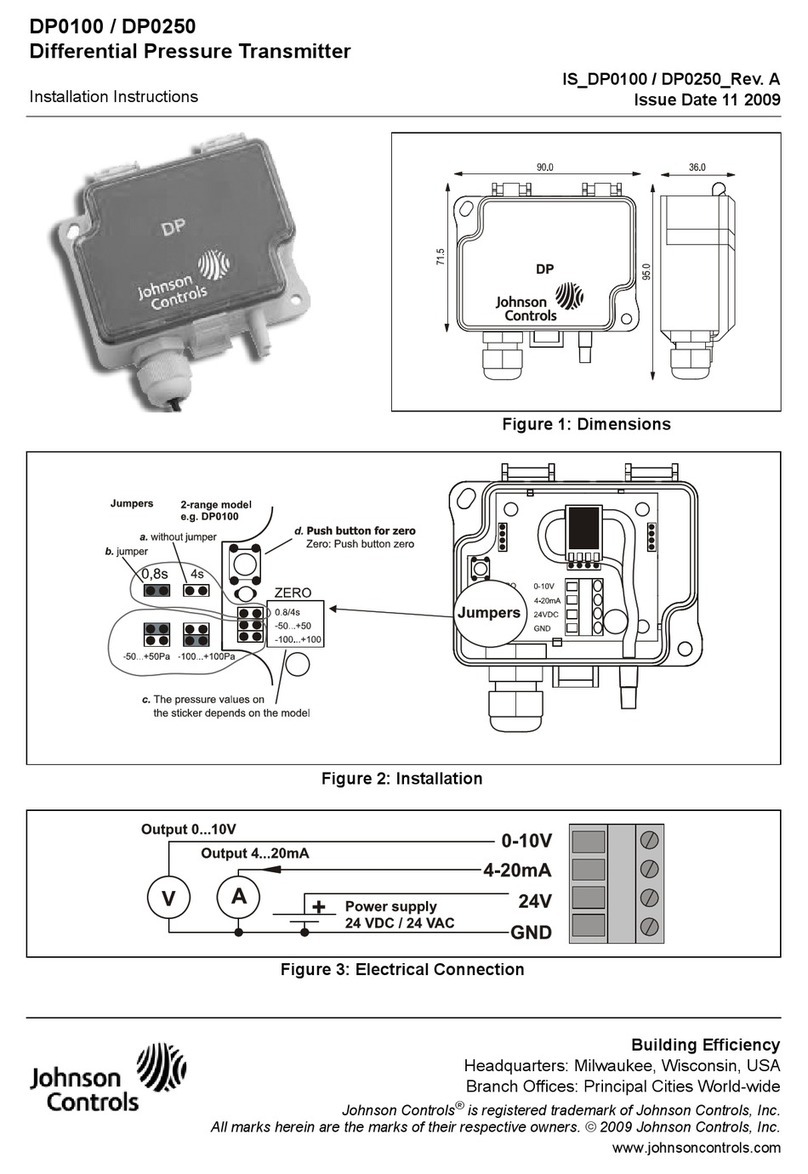

1. Connect the RS-485 network with a twisted shielded

pair to the terminals marked A-, B+, and SHIELD.

The positive wire connects to B (+), the negative

wire connects to A (-), and you must connect the

cable shield to the SHIELD terminal on each device.

See Figure 6.

Figure 6: Wiring connections

Figure 7: Daisy chain configuration

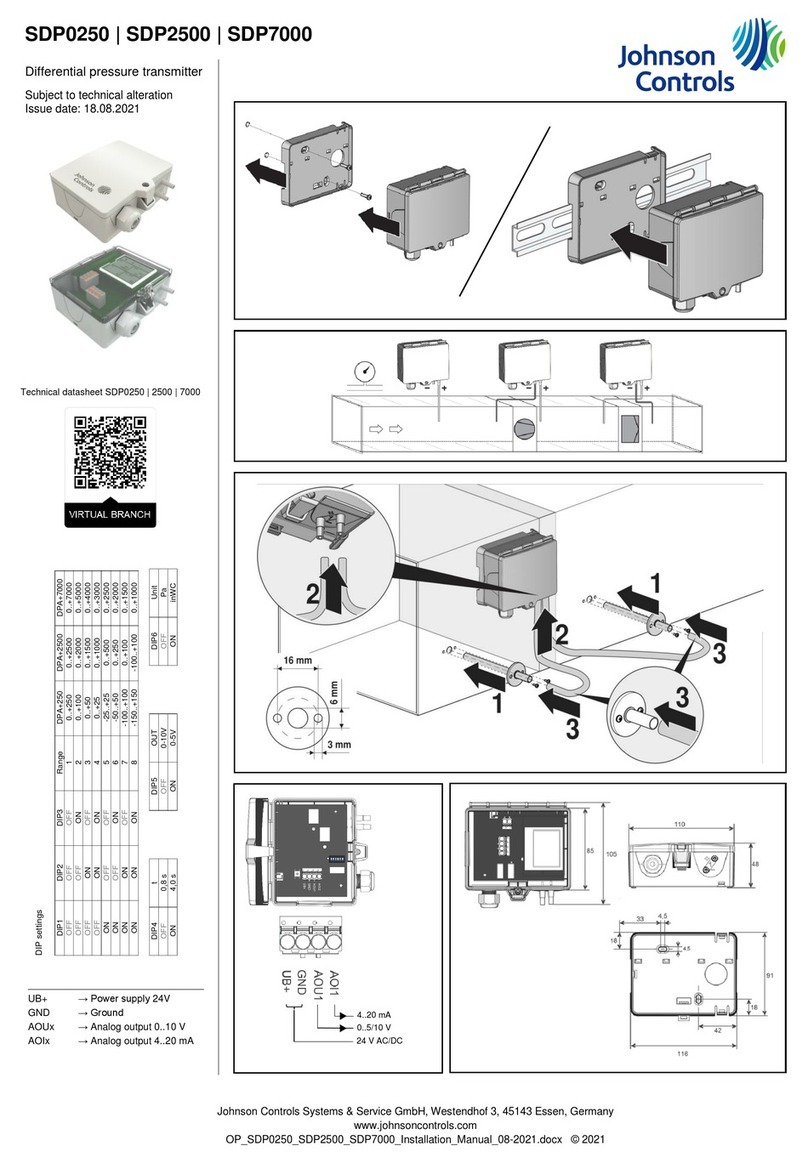

2. To install more devices, or to increase the network

length, requires the use of repeaters for correct

communication. The maximum daisy chain

length (segment) depends on transmission speed

(baud rate), wire size, and number of nodes. If

communication is slow or unreliable, it may be

necessary to wire two daisy chains to the controller

with a repeater for each segment. See Figure 7.

Network communication

Each device must have a unique Modbus address for

start-up and you must set the Modbus address before

connection to the network. Use the local DIP switch to

set the Modbus device address from 1 to 255. The factory

default baud rate is 9600. Other Modbus parameter

settings can be found in Modbus protocol. The CO sensor

operates as a subordinate and will not communicate

unless a master connects to the network. When the

master sends a request for information, the subordinate

answers the request.

If the device does not communicate correctly, first check

that you did not reverse the communication wires.

Then check that the subordinate address, baud rate,

transmission mode, parity bit, stop bit, and RTU mode

CRC polynomial are correct. Set the device address. See

GS3000 Indoor Modbus Carbon Monoxide Transmitter Installation Guide2