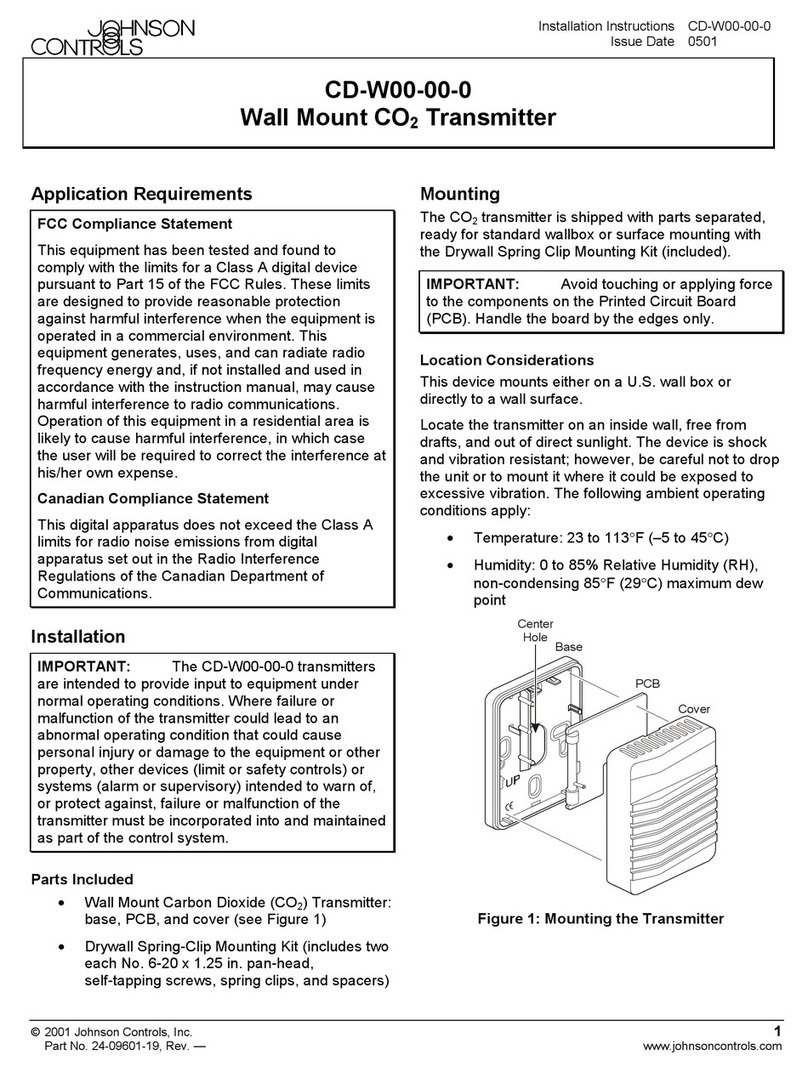

Mounting

The transmitter installs directly into any air duct with a

minimum width or diameter of 10 in. (25.5 cm).

- Select a suitable installation area in the middle of

the duct wall.

- To achieve the best reading, do not place in an area

where air stratification may be present.

- Mount the sensor at least 5 ft. (1.5 m) in either

direction from elbows, dampers, filters, or other

duct restrictions.

- Avoid areas that expose the transmitter to

vibrations or rapid temperature changes.

To install the transmitter, complete the following steps:

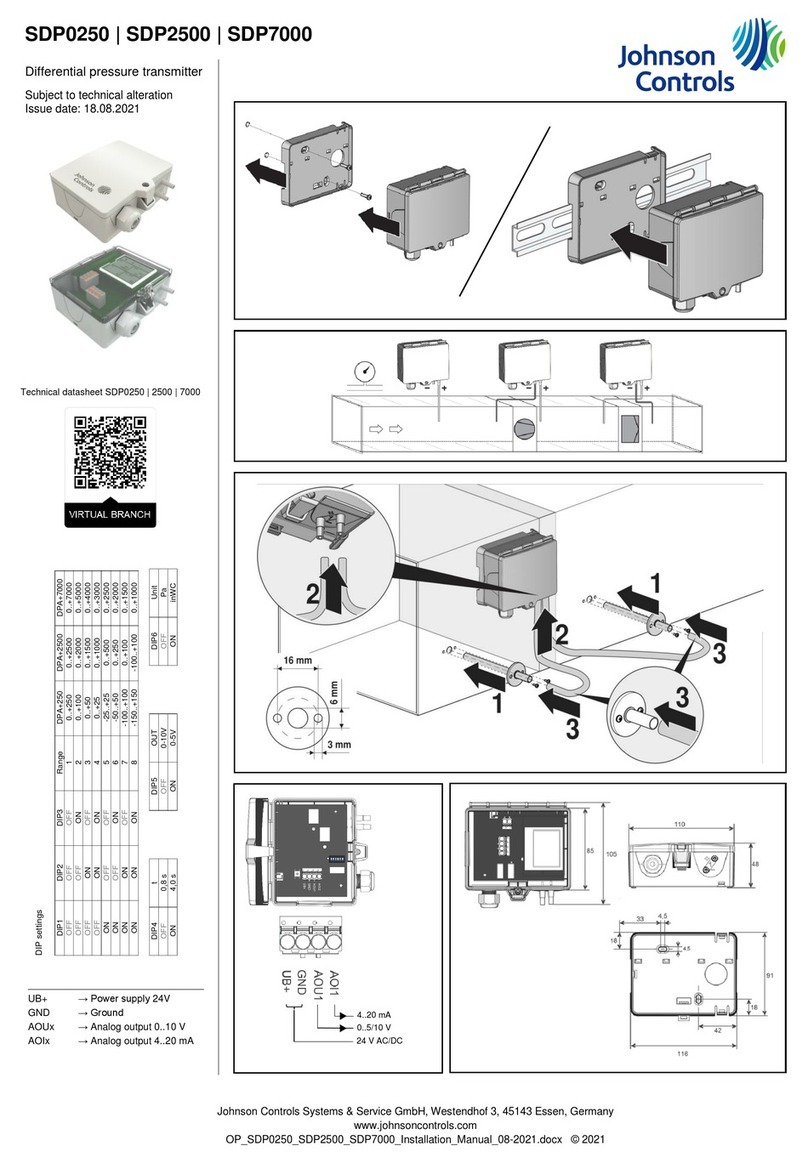

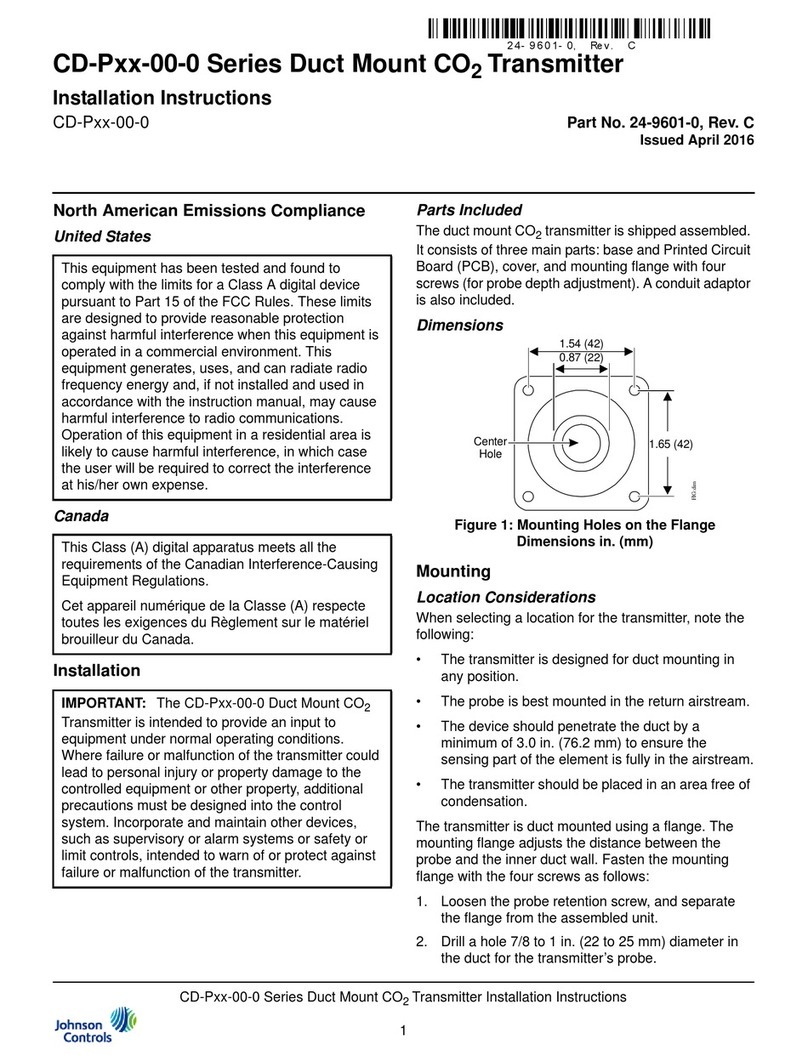

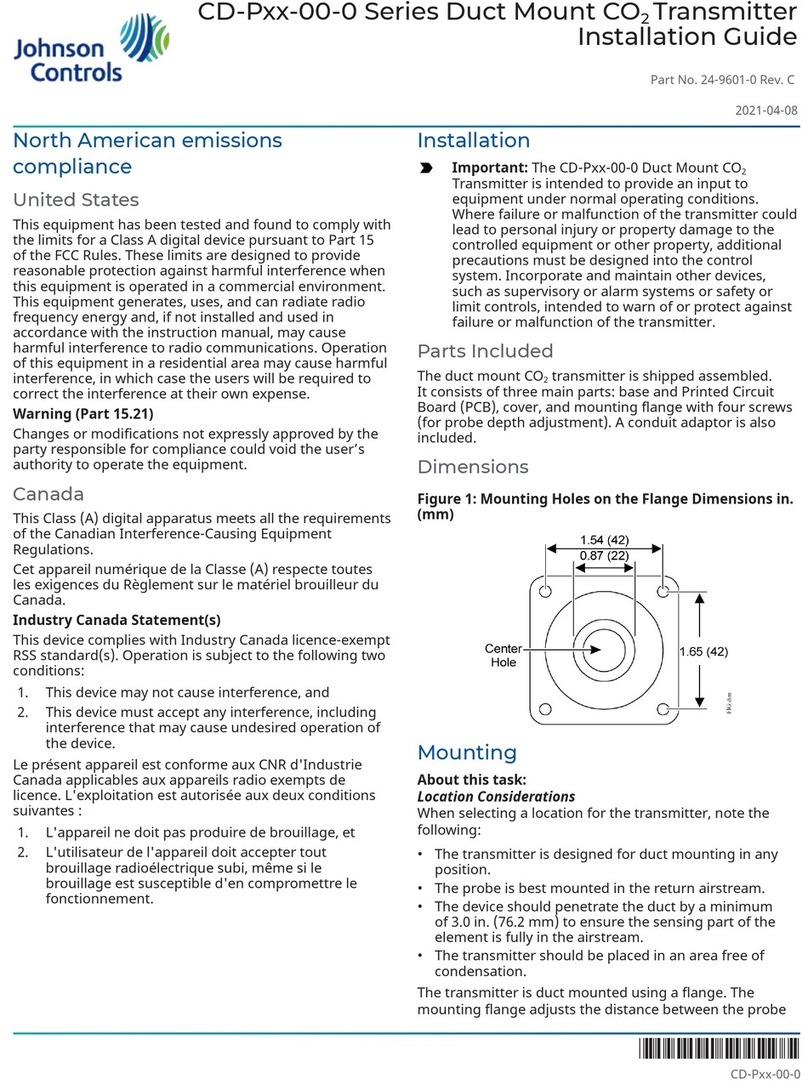

1. When you select a suitable spot, drill a 0.6 in. (15

mm) to 0.75 in. (20 mm) hole for the probe.

2. Slide the probe into the drilled hole until the

enclosure is flush against the duct. The airflow

direction is not important.

3. Secure the enclosure to the duct with two No. 10 x

1 in. (25 mm) self-tapping screws (not provided).

4. Tighten the screws until the enclosure is tight

against the duct so that there is no movement

of the enclosure. A foam gasket on the back of

the enclosure provides a tight seal against any air

leaks. See Step 1 in Figure 3.

5. The enclosure includes a hinged cover with a latch.

To open the cover, pull slightly on the latch on the

right side of the enclosure. At the same time, pull

on the cover as shown in Step 2 of Figure 3.

6. A 0.5 in. NPT threaded connection hole is in the

bottom of the enclosure. Screw the EMT or cable

gland connector into the threaded connection hole

until tight. See Step 3 in Figure 3.

Note: Preferably use weatherproof EMT or

cable gland fittings. The E-style enclosure

includes 0.5 in. NPT to M16 thread adaptor

and cable gland fitting.

7. Make wire connections as shown in the wire

diagram in Wiring.

8. Swing the door closed until it securely latches. For

added security, install the two provided screws in

the integrated screw tabs. See Step 4 of Figure 3.

Wiring

• Deactivate the 24 VAC/DC power supply before you

make all connections to the device to prevent electrical

shock or equipment damage.

• Use 14 AWG to 22 AWG shielded wiring for all

connections and do not locate the device wires in the

same conduit with wiring that supplies inductive loads

such as motors. Make all connections in accordance

with national and local codes.

• Pull at least 6 in. (15 cm) of wire into the enclosure,

then complete the wiring connection according to

the wire diagram for the applicable power supply and

output signal type. See Figure 4.

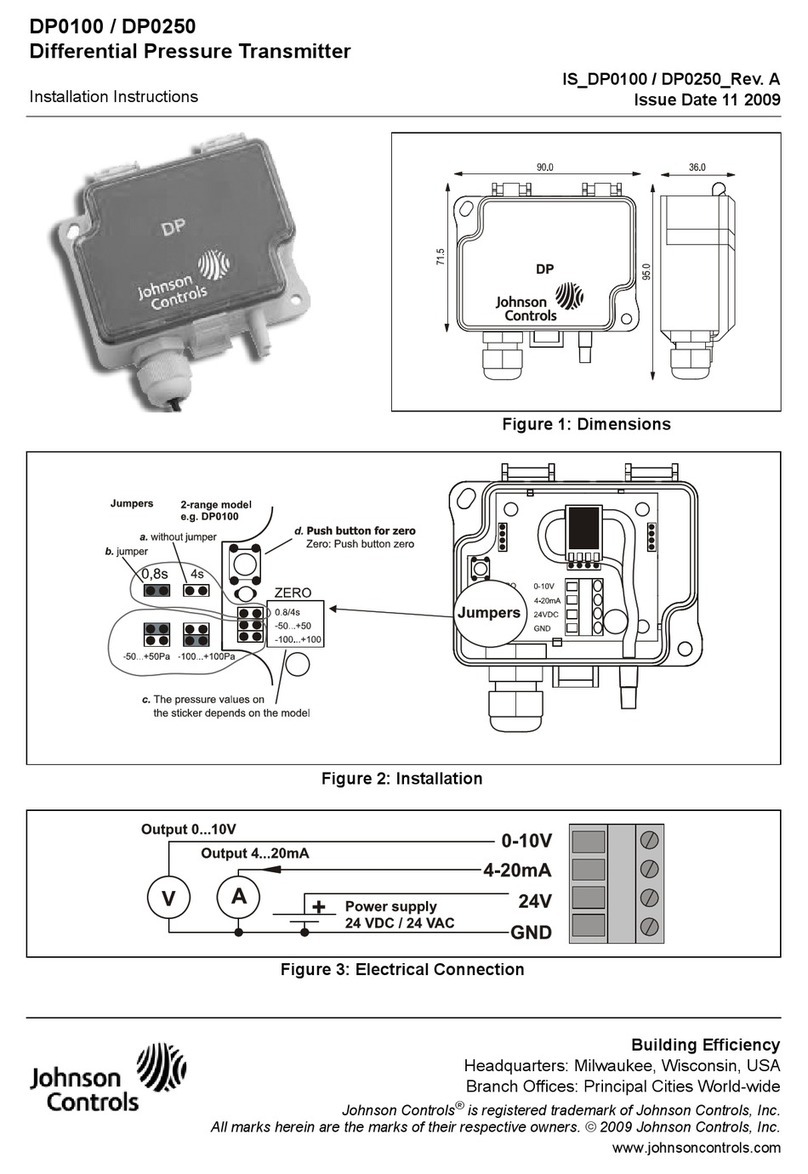

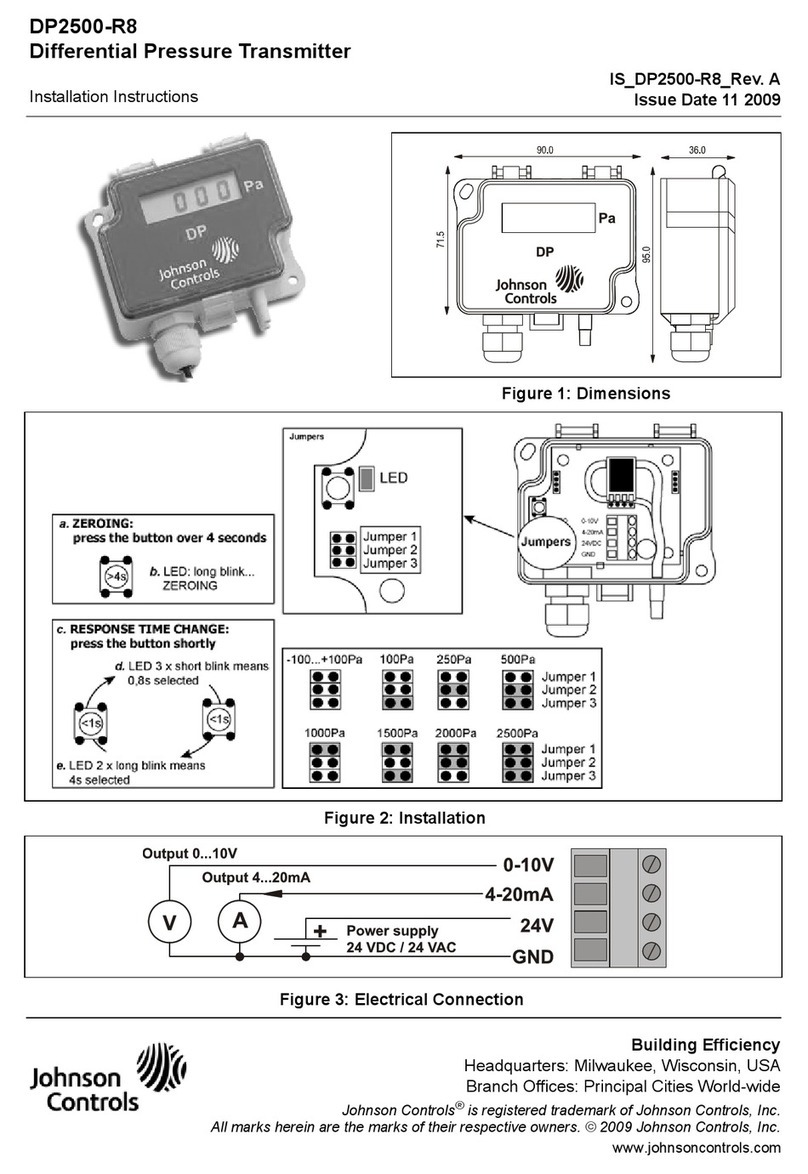

• Place the output switch in the required position to

select the required signal output type (mA or VDC), as

shown in Step 2 of Figure 4. The factory default setting

is 4 mA to 20 mA.

• If you select mA, no further output set up is required.

If you select VOLT output as shown in Figure 5, place

the voltage output switch to the required span position,

that is 10 VDC = 0 VDC to 10 VDC. The factory default

setting is 0 VDC to 10 VDC. See Step 1 of Figure 4.

• Connect the DC positive or the AC voltage hot side to

the PWR terminal. For voltage output or AC power,

connect the supply common to the COM terminal.

The device is reverse voltage-protected and does

not operate if you connect it backwards. The device

contains a half-wave power supply so the supply

common is the same as the signal common. See Step 3

of Figure 4.

• The analog output is available on the OUT terminal.

Check the controller Analog Input to determine the

correct connection before you apply power as shown in

Step 3 of Figure 4.

HT-69020NP-0, HT-69030NP-0 Duct Probe RH Transmitter Installation Guide2