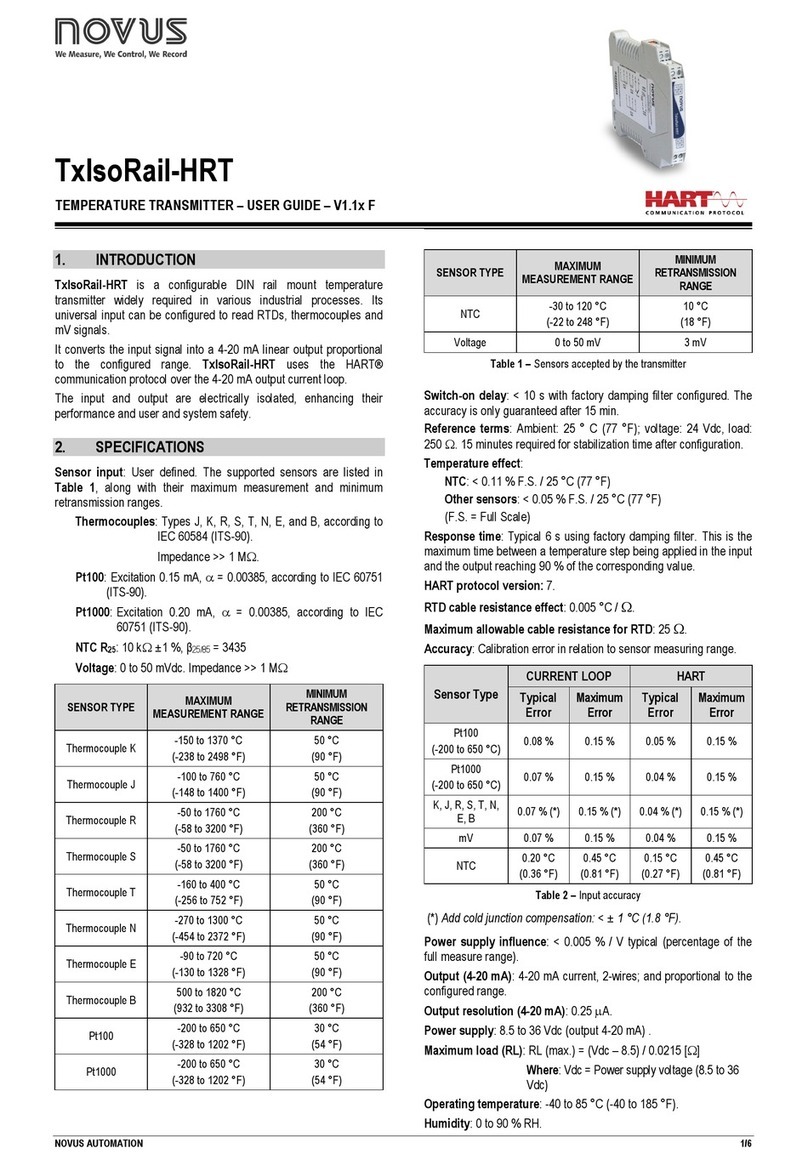

NOVUS AUTOMATION 2/3

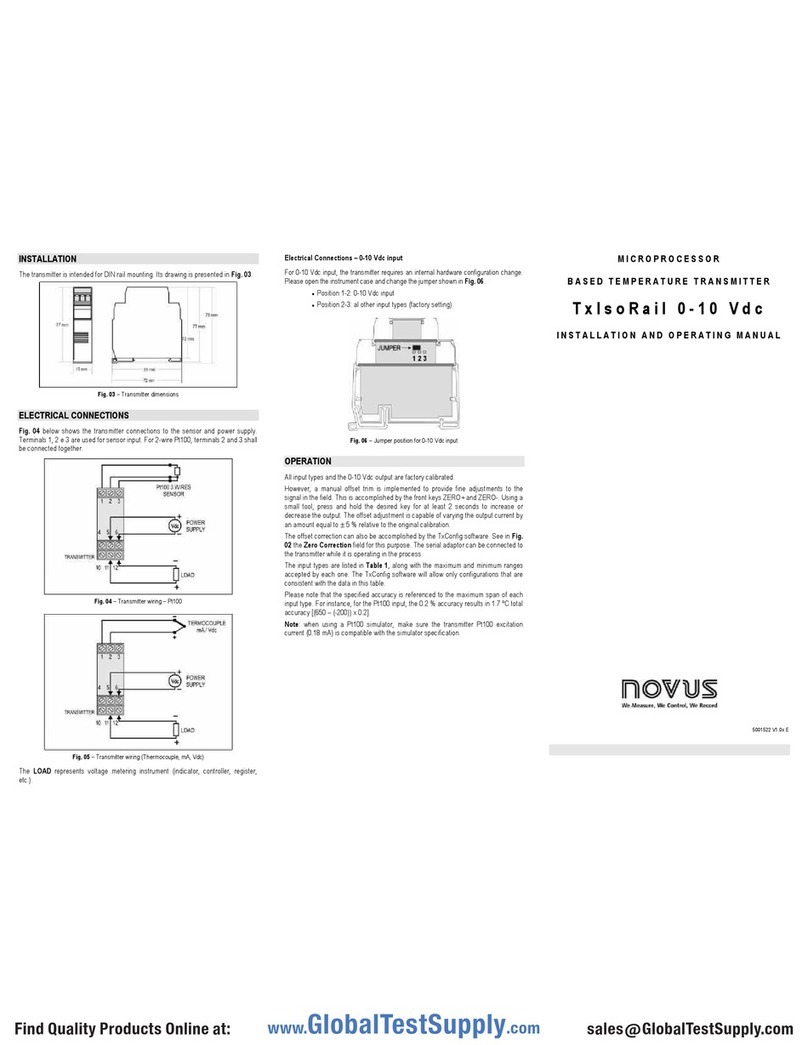

The TxConfig screen in shown in Fig. 3.

Fig. 3 – TxConfig main screen

The fields in the screen mean:

1.Input Sensor:Select the sensor to be used. See Table 1.

2.Measuring Range: Define the transmittermeasurement range.

Range Lower Limit: temperature desiredfor a 4 mA current.

Range Upper Limit: temperature desiredfor a 20 mA current.

When the Lower Limit is set with a value greater than the Upper

Limit value of the output current operates from 20 to 4 mA (the

current decreases as the temperature increases).

Note:The values chosen can not exceed the Sensor Range shown

in this same field, and also may not establish a range with width

(span) smaller than the Min. Range indicated later in this same field.

See Table 1 of this guideline.

3.Sensor Failure: It establishes the output behavior, when the transmitter

indicatesa failure:

Minimum:output currentgoes to 3.8 mA (down-scale), typically used for

refrigeration.

Maximum: output current goes to 20.5 mA (up-scale), typically used for

heating.

4.Device Information: This field contains the data identifying the

transmitter. This information must be submitted to the manufacturer for

anyqueries.

5.Zero Correction: It corrects small deviations presented in the transmitter

outlet, for example, when the sensor is replaced.

6.Send Configuration: It applies the new setup. Once sent, the setup will

be immediatelyadoptedby the transmitter.

7.Read Configuration: Reads the current setup in the transmitter

connected. The screen now presents the current setup that may be

changed bythe user.

Note: The factory default configuration is:

•Sensor Pt100, range0 to 100 °C, 0 °C of zero correction.

•Output at maximum for the sensor failures.

Upon purchase order, the user can definea specific setup.

MECHANICAL INSTALLATION

The TxIsoPack transmitter is suitable to be installed in heads. Vibrations,

moisture and extreme temperatures, electro-magnetic interference, high

voltage andother interferences can permanently damage the unit, and could

cause errorin the measured value.

DIMENSIONS:

Fig. 4 – Transmitter dimensions

ELECTRICAL INSTALLATION

Polyamide enclosure.

Section of the cable used: 0.14 to 1.5 mm².

Recommended torque in the terminal: 0.8Nm.

RECOMMENDATIONS FOR INSTALLATION

•Sensor signals conductors must go through the plant system separate

from powerleads (loop),if possible in grounded conduits.

•The instruments must be powered from the instrumentation power supply

circuit.

•In control and monitoring applications is essential to consider what can

happen when anypart of the system fails.

•It is recommended the use of suppressors in contact coils, solenoids and

any inductive load.

•Use compensation cables in the connections using thermocouples.

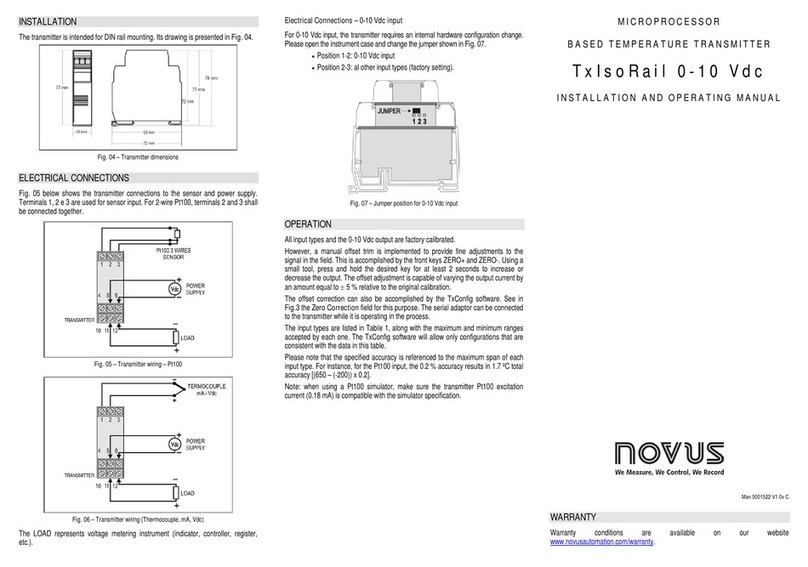

ELECTRICAL CONNECTIONS

The figures below show the electrical connections required. The terminals 3, 4,

5 and 6are dedicated to the sensor connection. LOAD represents the 4-20 mA

current measuring device (indicator, controller, recorder, etc.)

PT100 2-WIRES

Note:When the Pt100 2-wires the terminals 3 and 4 mustbe interconnected,

according to the figure below.

Fig. 5– Transmitter electrical connections (Pt100 2-wires)