2

Table of Contents

Warnings 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using this Manual 2–3. . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 2–4. . . . . . . . . . . . . . . . . . . . . .

How the PrecisionMix II 3K Works 2–6. . . . . . . . . .

Functional Diagrams 2–7. . . . . . . . . . . . . . . . . . .

Changing the Mixing Order 2–10. . . . . . . . . . . . . . . .

Flow Control Overview 2–12. . . . . . . . . . . . . . . . . . .

Flow Control Features 2–12. . . . . . . . . . . . . . . .

System Requirements 2–12. . . . . . . . . . . . . . . .

General Operation Sequence 2–12. . . . . . . . . .

One Gun Flow Control Using a Flow Meter

in the Mixed Material Line 2–13. . . . . . . . . .

Flow Control Components 2–14. . . . . . . . . . . . .

Flow Control Parameters 2–15. . . . . . . . . . . . . .

Using Recipes/Color Change 2–16. . . . . . . . . . . . . .

No Color Change 2–16. . . . . . . . . . . . . . . . . . . . .

Integrated Color Change 2–16. . . . . . . . . . . . . .

Integrated Color Change with Queue 2–17. . . .

Color Change Sequences 2–18. . . . . . . . . . . . .

Changing from One Color Change

Sequence to Another 2–19. . . . . . . . . . . . . .

Actual Valve Times 2–20. . . . . . . . . . . . . . . . . . .

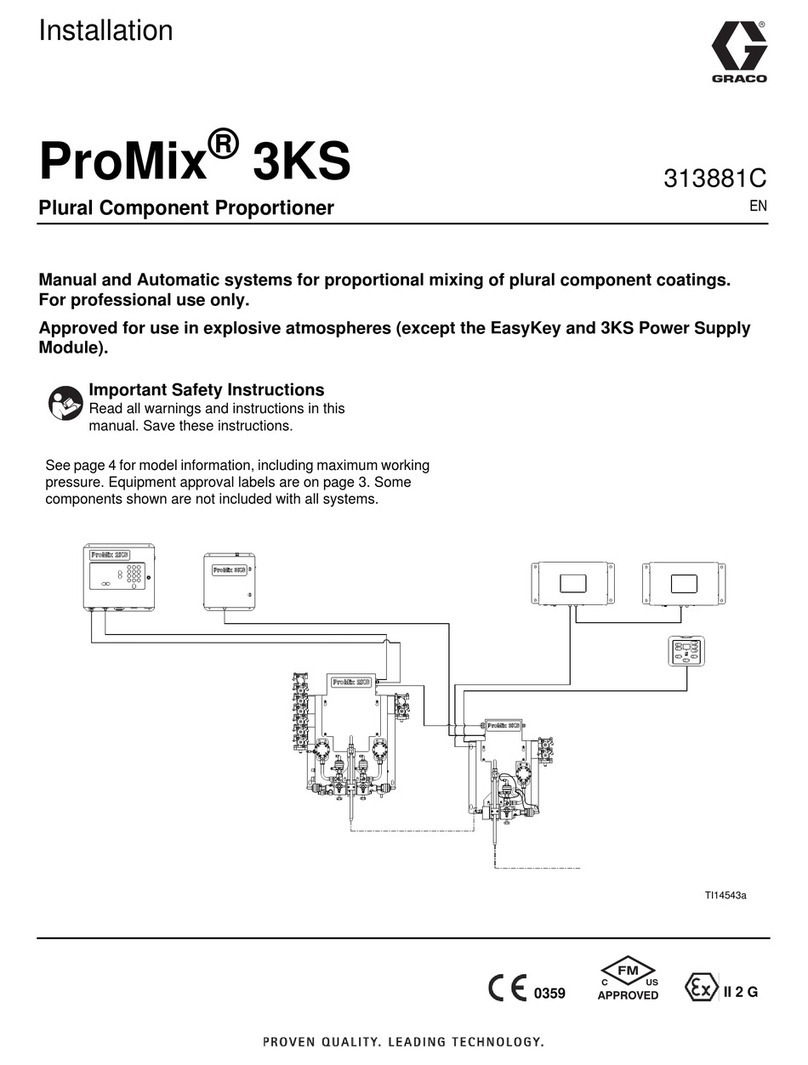

Installation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

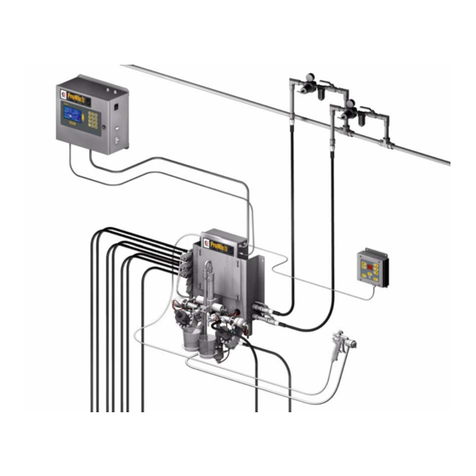

Typical Installation 3–3. . . . . . . . . . . . . . . . . . . . . . . .

Non-intrinsically Safe 3–4. . . . . . . . . . . . . . . . . .

Intrinsically Safe 3–5. . . . . . . . . . . . . . . . . . . . . .

Fluid Supply Requirements 3–6. . . . . . . . . . . . . . . . .

Mounting Components 3–7. . . . . . . . . . . . . . . . . . . .

For Wall Mounting 3–7. . . . . . . . . . . . . . . . . . . . .

Stand Mounting Kit 241501 3–9. . . . . . . . . . . . .

System Installation 3–10. . . . . . . . . . . . . . . . . . . . . . .

Install the Controller and User Interface 3–10.

Power Requirements 3–11. . . . . . . . . . . . . . . . .

Install the Fluid Panel with Fluid Meters 3–12.

Install the Air Control Kit 3–13. . . . . . . . . . . . . .

Install the Operator Station 3–13. . . . . . . . . . . .

Install the Color/Catalyst/Reducer

Change Valves and Solenoids 3–14. . . . . .

Install the Gun Flush Box and

Solenoid Box 3–16. . . . . . . . . . . . . . . . . . . . .

Install the Optional Flow Control 3–20. . . . . . . .

Fluid Connections 3–20. . . . . . . . . . . . . . . . . . . .

Pressure Test and Solvent Flush

the System 3–20. . . . . . . . . . . . . . . . . . . . . .

Digital Outputs 3–21. . . . . . . . . . . . . . . . . . . . . . .

Component Electrical Connections 3–22. . . . . . . . .

Controller Terminal Block 3–29. . . . . . . . . . . . . . . . .

Ground the System 3–30. . . . . . . . . . . . . . . . . . . . . .

Check the Resistance 3–31. . . . . . . . . . . . . . . . . . . .

Power-up Checklist 3–32. . . . . . . . . . . . . . . . . . . . . .

Checking Flow Control I/P Transducers 3–34.

Testing Flow Control External 4–20 mA Input

Signal 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Test and Solvent Flush Procedure 3–36.

Test Color Valve Operation 3–36. . . . . . . . . . . .

Pressure Test Component A 3–36. . . . . . . . . . .

Pressure Test Component B and C 3–36. . . . .

Pressure Test the Solvent Lines 3–36. . . . . . . .

Operation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 4–3. . . . . . . . . . . . . . . . .

Operator Controls and Indicators 4–4. . . . . . . . . . . .

Operator Station 4–4. . . . . . . . . . . . . . . . . . . . . .

User Interface 4–6. . . . . . . . . . . . . . . . . . . . . . . .

Operating Checklist 4–7. . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging the Ratio Check Valves 4–8. . . . . . . . . . . . .

Purging the PrecisionMix II 3K System 4–10. . . . . .

Starting Production 4–12. . . . . . . . . . . . . . . . . . . . . . .

Stopping Production 4–14. . . . . . . . . . . . . . . . . . . . . .

Flow Control Operation 4–15. . . . . . . . . . . . . . . . . . .

Flow Control Tips 4–15. . . . . . . . . . . . . . . . . . . . . . . .

Integrated Color Change 4–16. . . . . . . . . . . . . . . . . .

Multiple Gun Flush Box Operation 4–16. . . . . . . . . .

Printer Reports 4–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Run Mode Report 4–18. . . . . . . . . . . . . . . . . . . .

Recipe Report 4–19. . . . . . . . . . . . . . . . . . . . . . .

System Setup (Configuration) Report 4–20. . .

Job Totals Report 4–22. . . . . . . . . . . . . . . . . . . .

Batch Totals Report 4–22. . . . . . . . . . . . . . . . . .

Grand Totals Report 4–23. . . . . . . . . . . . . . . . . .

Alarm Report 4–23. . . . . . . . . . . . . . . . . . . . . . . .

Screen Map 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Monitor 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Screen 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Target/Actual 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Rate 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potlife Timer 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Rate Setpoint 6–5. . . . . . . . . . . . . . . . . . . . . . . .

Enter New Setpoint 6–5. . . . . . . . . . . . . . . . . . . . . . .

Recipe Select 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm History 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Color Change with Queue 6–7. . . . . . . .

Modify Queue Screen 6–8. . . . . . . . . . . . . . . . . . . . .

Totalizers 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Screen 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Recipe and Totalizer Screen 7–3. . . . . . . . . .

Job Totals 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batch Totals 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grand Totals 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .