Screw

adjuster

Water

supply hose

Bolt

3/4

Valve may be removed for

service - twist to unlock

Capnut must be hand tightened to

correctly seal flush pipe

Button rods must be just clear of

the valve pads

Button rods can be adjusted

by screwing up or down

Half

flush

Full

flush

Moving the float DOWN increases the half flush

Moving the float UP decreases the half flush

Half flush volume can be adjusted by moving the side float up or down.

Move the adjuster UP to decrease the volume.

The full flush volume can be adjusted by changing the residual water level in the cistern.

Move the adjuster DOWN to increase the volume.

OUTLET VALVE SERVICE

Removal Assembly Push button rod settings

Full flush adjustmentHalf flush adjustment

Ensure that buttons

match valve pads

Rubber washer

Flat washer

Capnut

INLET VALVE SERVICE VALVE SERVICE

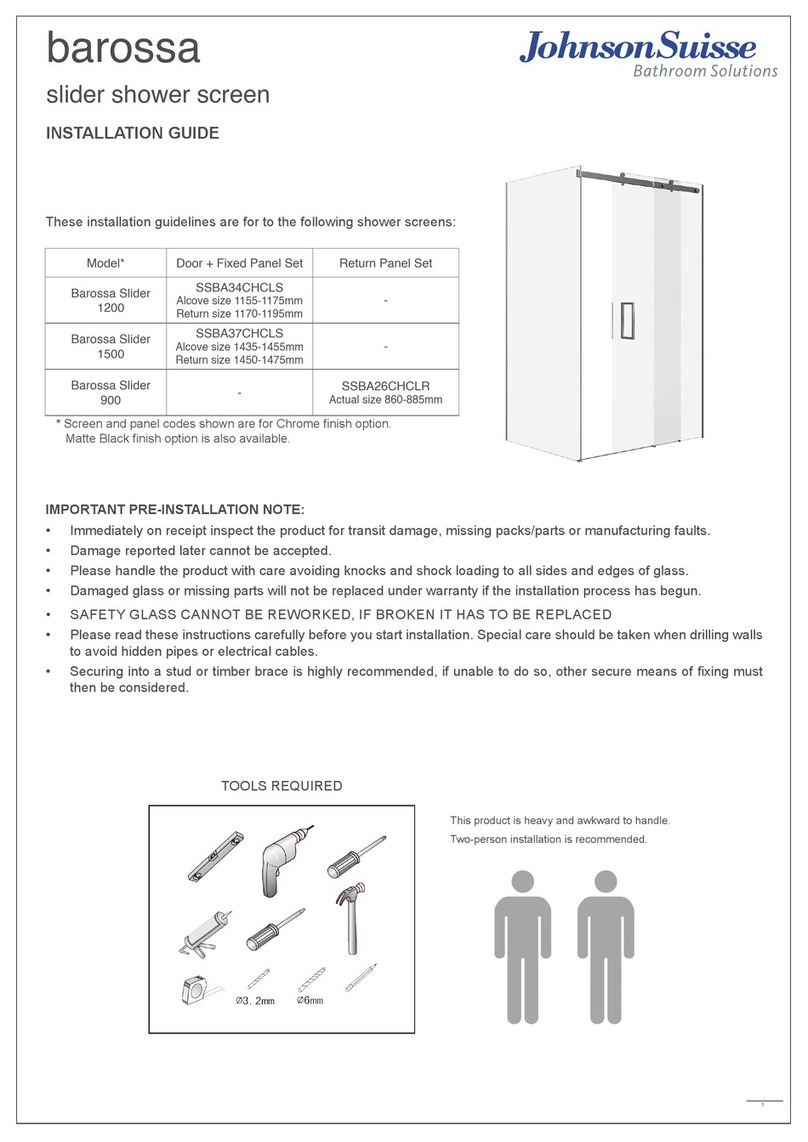

Please read and follow these step-by step instructions to ensure

correct installation

Operating environment

•When the outlet valve is installed there must be a

minimum gap of 25mm between the top of the overflow

tube and the Critical Level (CL) mark on the inlet valve.

Note that specifications and packaging

may change without notice

•Water temperature 2-45ºC

•Water pressure 0.02-1.0MPa

IMPORTANT

•Remove cistern lid

•Flush the cistern to

empty the water from the

tank

•Measure the water

depth in the tank

•Turn off water supply

Disconnect the water

supply hose

Unscrew the clip bracket

bolt and remove the valve

from the overflow tube •Fit the new inlet valve

to the overflow tube and

tighten the clip bracket

bolt

•Test flush

•Reconnect the water

supply hose

•Turn on supply and

check for connection

leaks

•Turn the screw adjustment

clockwise (anticlockwise) tpo

increase (decrease) the level

•Measure the water depth and

adjust to previous level

VALVE REPLACEMENT INSTRUCTIONS

1 2 3 45

1. Follow Steps 1, 2, 3 above

5. Re-assemble in reverse order

3. Remove the filter component

In some areas, it may be necessary to clean the

internal grit filter:

2. Unscrew the main nut to separate the inlet

connector from the valve body

4. Rinse under running water to remove any

dirt/debris

5. Re-assemble in reverse order

To remedy this, the diaphragm may be cleaned as follows:

3. Twist the plastic housing firmly anti-clockwise and remove it from

the valve body

If dirt/debris accumulates under the diaphragm it can prevent the valve

from closing properly

1. Follow Steps 1, 2, 3 above

2. Unclip the float arm from the top of the adjustment screw

4. Inspect rubber diaphragm and valve seat. Rinse under running

water to remove any dirt/debris

CLEANING THE FILTER CLEANING THE DIAPHRAGM

Filter

98

57

Overflow

tube

CRITICAL

LEVEL

Min 65

Max 145

WL