Pentair PRO SHALLOW SN Series User manual

Other Pentair Water Pump manuals

Pentair

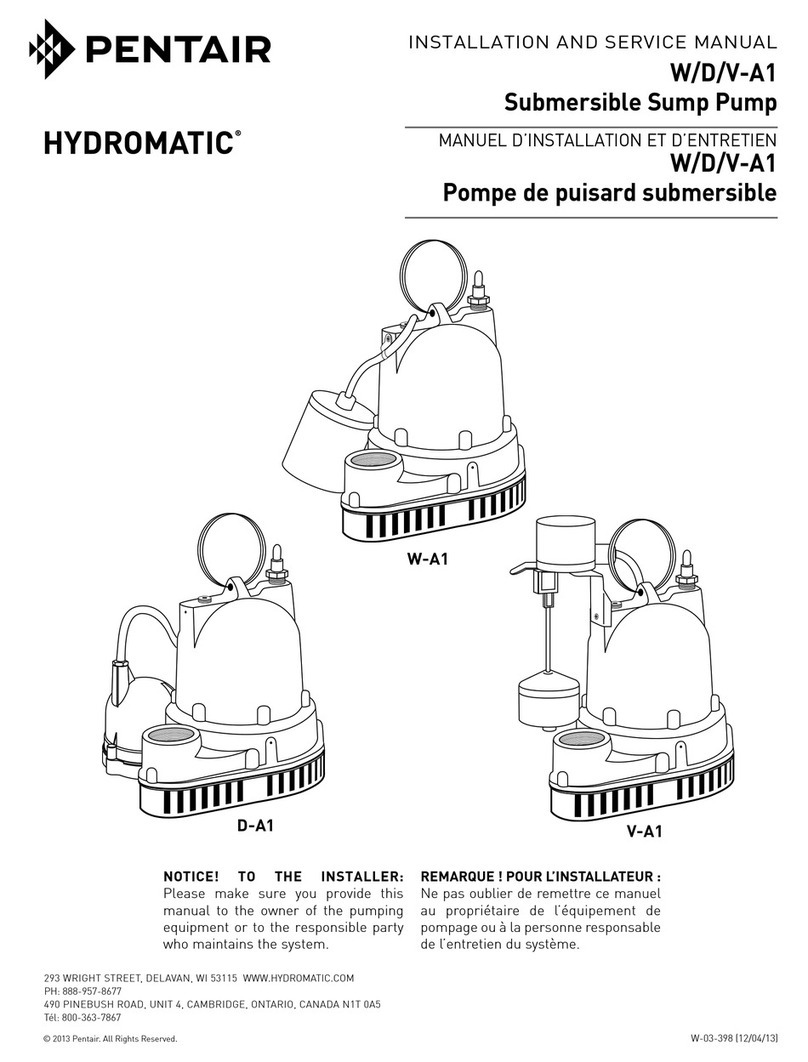

Pentair Hydromatic SKV50 Manual

Pentair

Pentair STA-RITE HMS-1FL Series User manual

Pentair

Pentair Jung Pumpen BASICLOGO AD 4 XE User manual

Pentair

Pentair WCFIX 260V/3 User manual

Pentair

Pentair AURORA LAYNE VERTI-LINE Series User manual

Pentair

Pentair MYERS WHV-5 Series Manual

Pentair

Pentair Hydromatic S3S Manual

Pentair

Pentair CP Series User manual

Pentair

Pentair Berkeley BVMI1 Guide

Pentair

Pentair Hydromatic Dry Pit Manual

Pentair

Pentair LA STA-RITE HD User manual

Pentair

Pentair MYERS B12-3036 Manual

Pentair

Pentair myers aplex Series Manual

Pentair

Pentair IntelliFloXF User manual

Pentair

Pentair AURORA 3801 Operating instructions

Pentair

Pentair ONGA VF150 User manual

Pentair

Pentair JUNG PUMPEN U 3 K/2 User manual

Pentair

Pentair Hypro 9303 Series User guide

Pentair

Pentair FLOTEC EVO-MULTIMAX 340 LOGIC SAFE User manual

Pentair

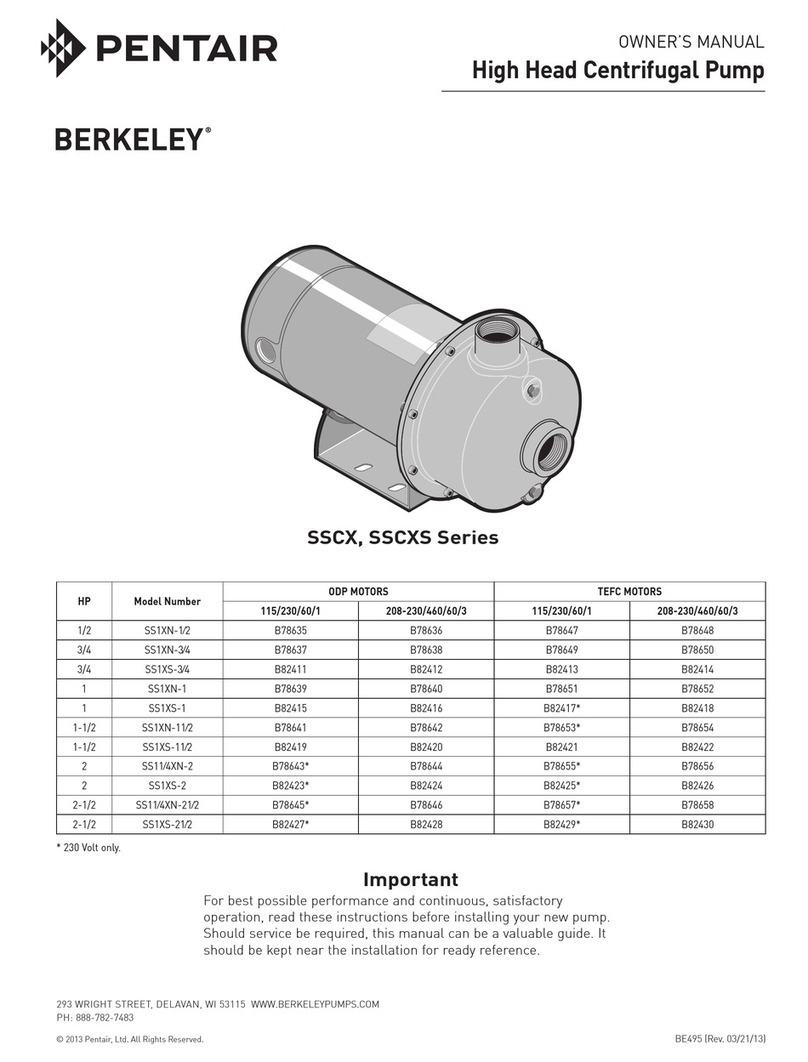

Pentair Berkeley SS1XN-1/2 User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual