[Jovy Systems Limited] Operating Manual

[Jetronix-Eco] [Version 1.01]

Jetronix-Eco Operating Manual

Page 4 of 22 ©Jovy Systems 2013. All rights reserved

1 Introduction

1.1 Purpose

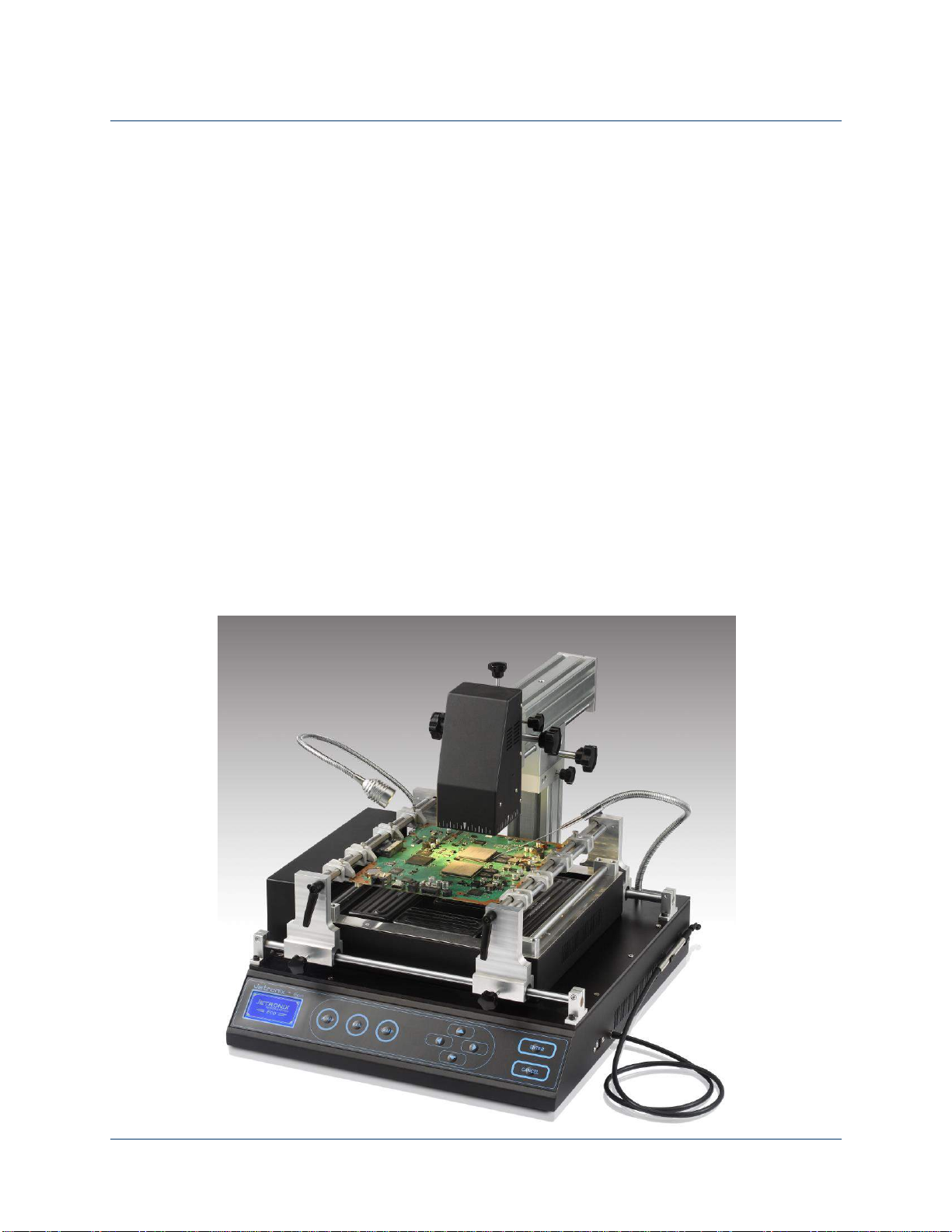

“Jetronix-Eco” Rework System is manufactured by Jovy Systems® Limited as the first product

in the Jovy Systems’ Economic Rework System lines. This operation manual provides the

detailed information about the product. Product feature shows what the product made for, as

well the field of application.

The Safety precaution is very important for user, product and work space safety. User should

follow and print it out if necessary

The Operating Manual provides a standard guide for the user. The user can develop own

operating method after complete understanding, following and practice the information in this

Manual.

The Operating Manual is the only reference for using Jetronix-Eco, it is recommended to read it

carefully before using the product.

1.2 Jetronix-Eco Features

Powerful machine: (max heating power: 3200 watt).

PID temperature control based microprocessor technology.

Three heating zones, Reflow zone, Inner preheating zone and Outer preheating zone.

Close loop heating environment.

Upper heater can move Up/Down, In/Out and rotate 180°.

Two Channels thermocouple real time temperature reading (one optional).

Flexible thermocouple mounting embedded in a Flexi - tube.

Large preheating area up to (245mmX245mm).

Three stages for full process control.

Separate preheating stage for uniform preheats.

Built in 1 Watt LED light source.

Powerful pickup tool up to 120gm lifting power.

Graphical widescreen LCD.

Elegant user interface design.

Saving up to 50 profiles in machine memory.

User friendly software interface via USB 2.0

Economical Rework Station with high performance.

Convenient work space.

Safety alarm functions to protect PCB or application damage.