(6) Setting sewing data for the round bar shape...................................................... 28

(7) Setting sewing data for the round bar 2 shape................................................... 28

(8) Sewing data list...................................................................................................... 29

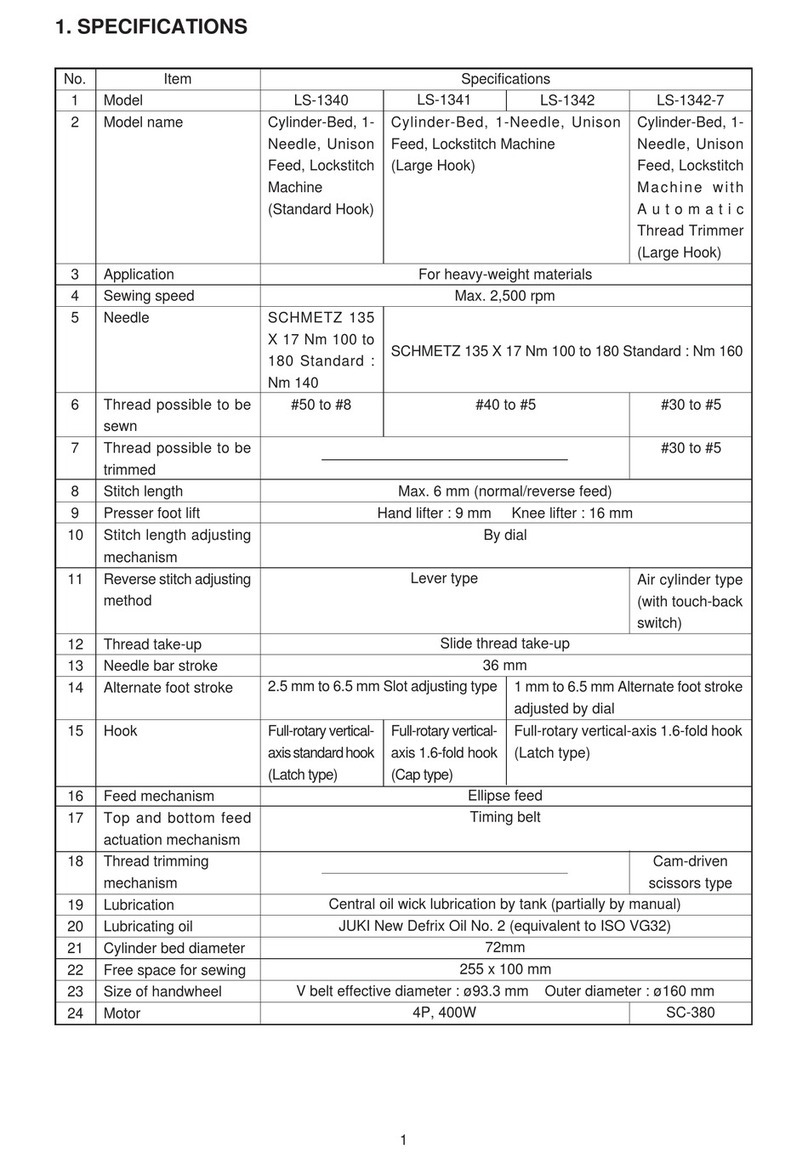

8. ADJUSTMENT OF EACH PART .............................................................. 34

(1) Replacing the cloth cutting knife and the knife holder ...................................... 34

(2) Setting the knife pressure of the standard type.................................................. 35

(3) Setting the knife pressure for the multicutting type........................................... 36

(4) Worn-out of the knife holder face......................................................................... 37

(5) Setting the material thickness of the cloth cutting knife ................................... 37

(6) Adjusting the stitch bite width.............................................................................. 38

(7) Adjusting the presser ............................................................................................ 39

(8) Adjusting the presser opening amount ............................................................... 39

(9) Adjusting the feeding amount of the needle thread ........................................... 41

(10) Adjusting the thread take-up thread guide........................................................ 41

(11) Adjusting the remaining amount of the gimp (J and C types) ......................... 42

(12) Adjusting the gimp thread tension (J and C types) .......................................... 42

(13) Hand LED light ..................................................................................................... 43

9. HOW TO USE THE VARIOUS FUNCTIONS ............................................ 44

(1) Performing procedure of the cycle sewing ......................................................... 44

(2) Operating procedure of thread tension compensation of each section........... 45

(3) Operating procedure of shape compensation of each section ......................... 47

(4) Changing the setting position of cloth ................................................................ 48

(5) Changing over the mode of the start switch ....................................................... 48

(6) Changing of the presser movement..................................................................... 48

(7) Changing over the counter (DOWN counting) .................................................... 49

(8) Stop before cloth cut mode................................................................................... 50

(9) Communication function....................................................................................... 50

10. MAINTENANCE...................................................................................... 52

(1) Height of the needle bar ........................................................................................ 52

(2) Timing between the needle and the looper ......................................................... 52

(3) Clearance between the needle and the looper.................................................... 54

(4) Adjusting the needle guard................................................................................... 54

(5) Installation positions of the spreaders and the timing to open/ close the

spreaders .............................................................................................................. 55

(6) Position of the presser foot and the needle entry point..................................... 57

(7) Adjusting the knife dropping position ................................................................. 57

(8) Installing position of the needle thread trimming knife ..................................... 58

(9) Adjusting the looper thread trimming.................................................................. 60

(10) Cleaning................................................................................................................ 61

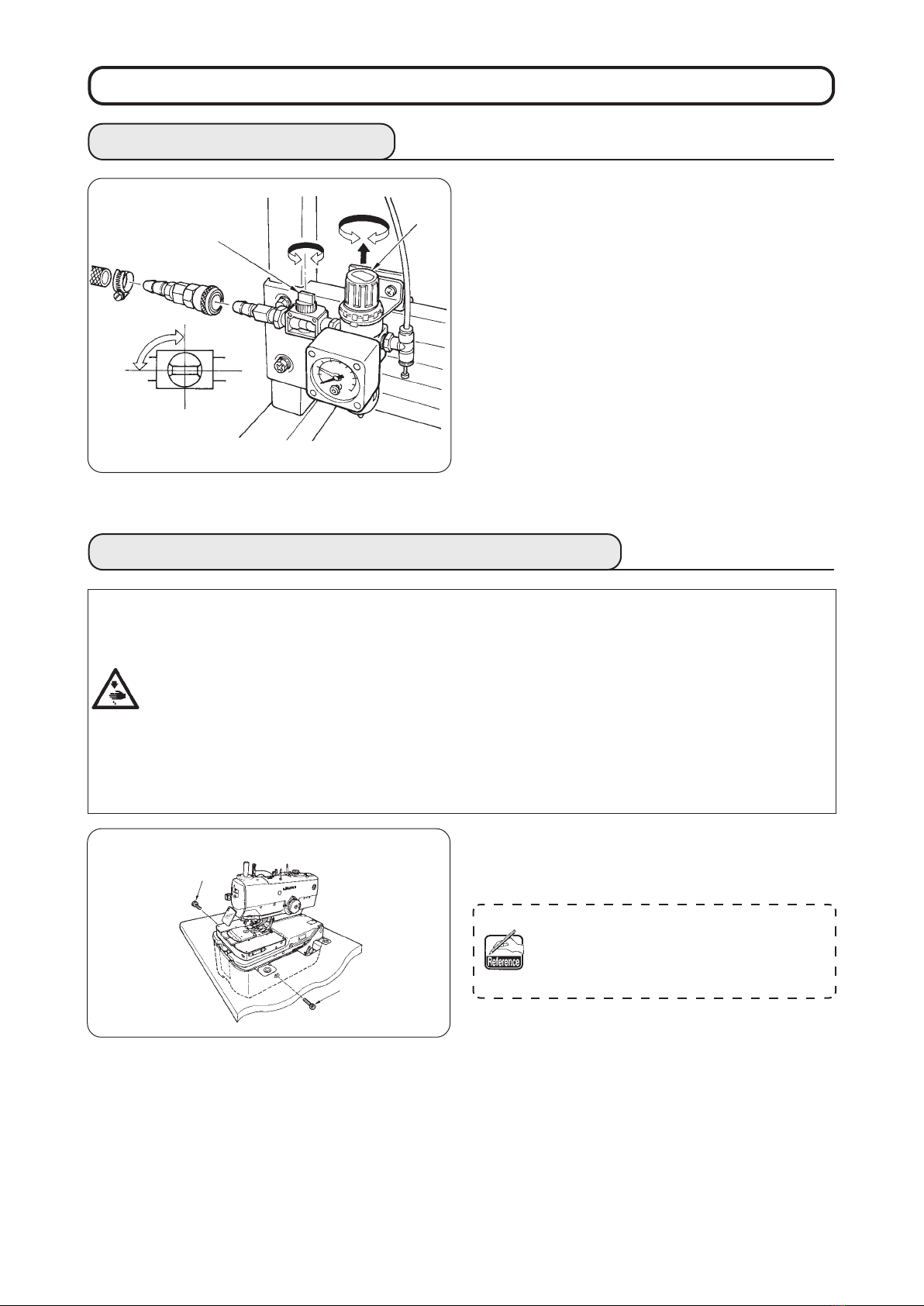

(11) Draining................................................................................................................. 61

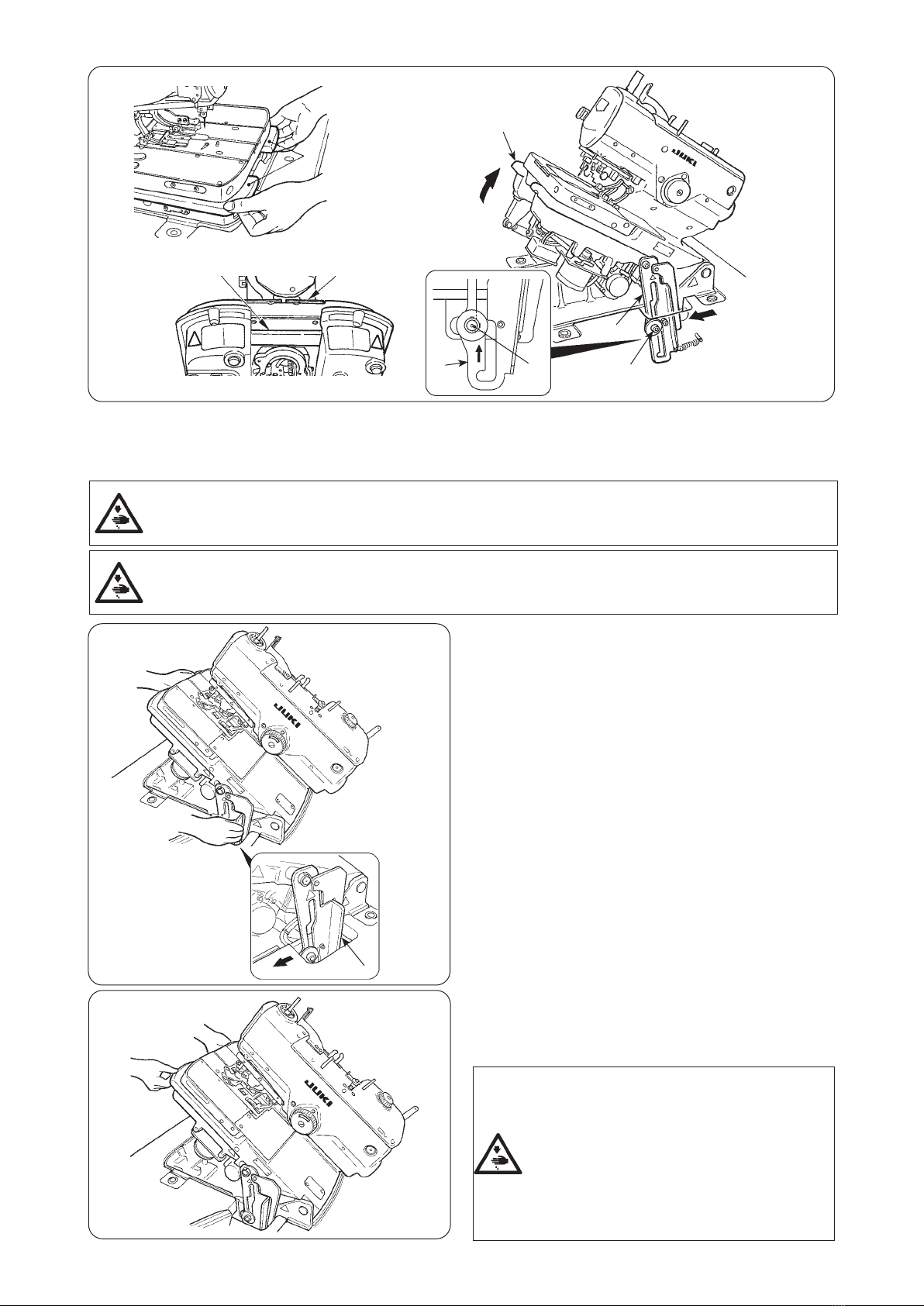

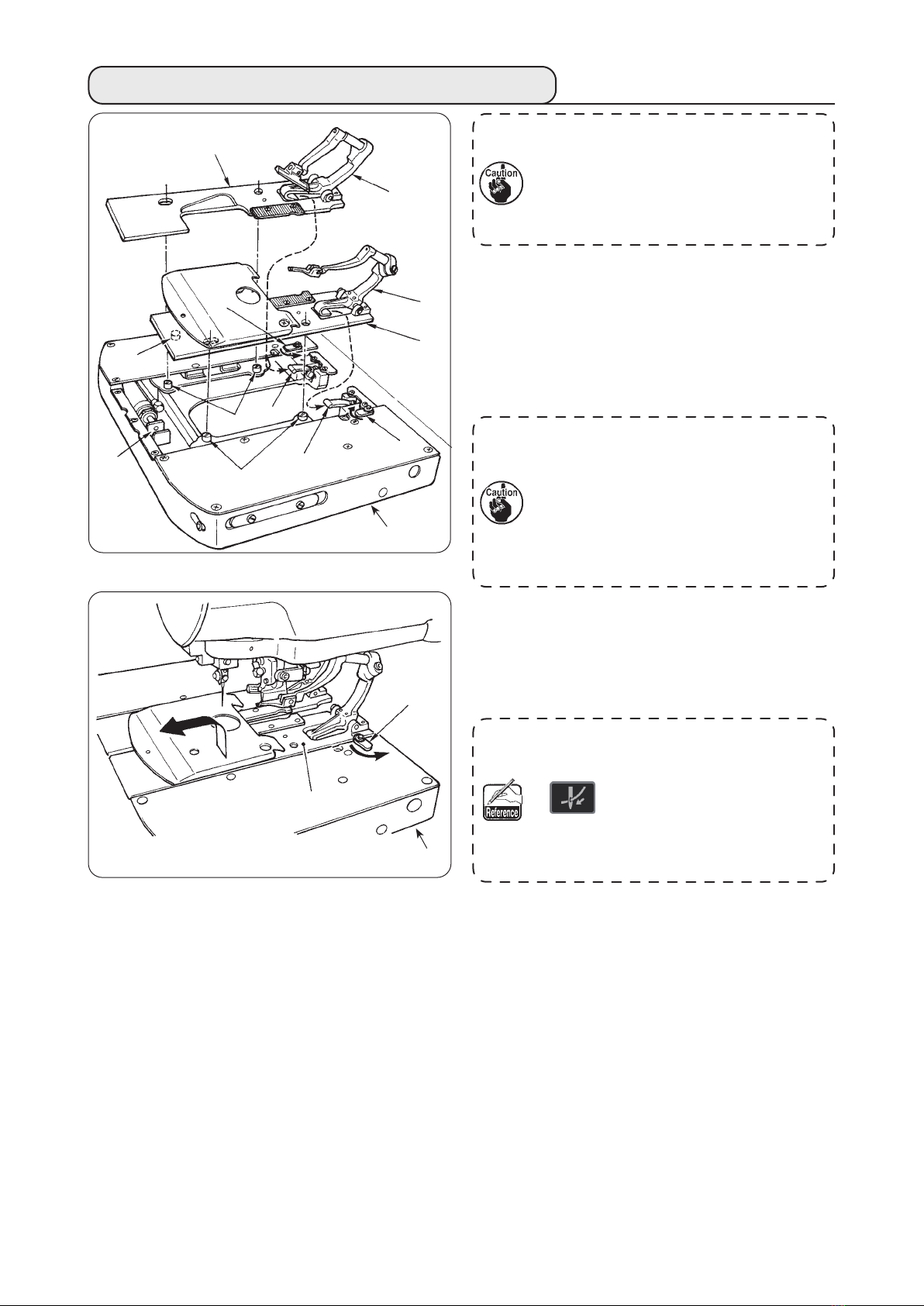

(12) Replacing the electrical control box .................................................................. 61

(13) How to change over the power supply .............................................................. 62

ii