CONTENTS

1. INTROdUCTION...................................................................................... 1

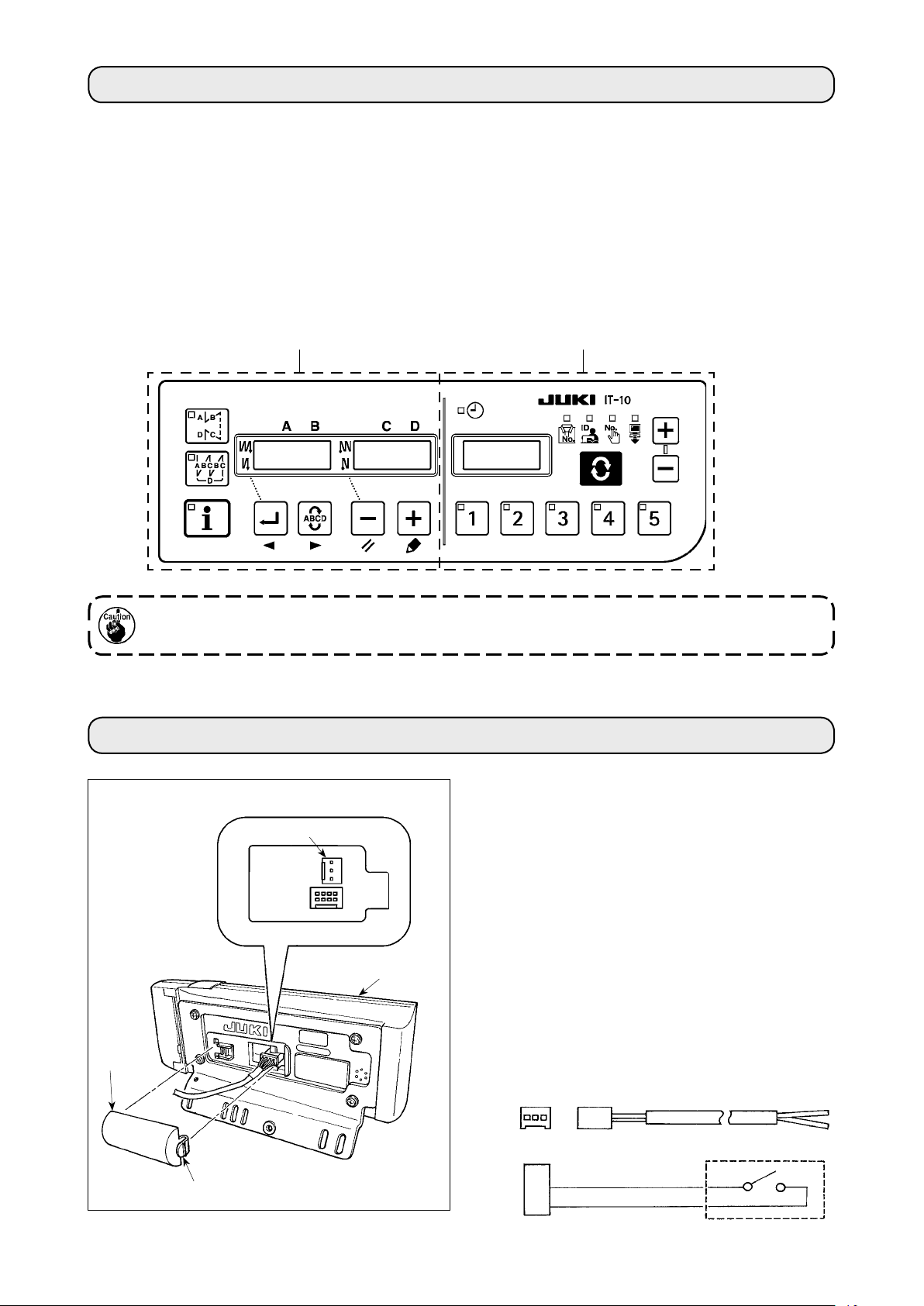

2. CONNECTING THE COUNT MANUAL SwITCH ................................... 1

3. USB pORT............................................................................................... 2

4. SETTING pROCEdURE Of THE MACHINE HEAd .............................. 2

5. AdjUSTING THE MACHINE HEAd(dIRECT-dRIvE MOTOR TypE

SEwING MACHINE ONLy) ..................................................................... 3

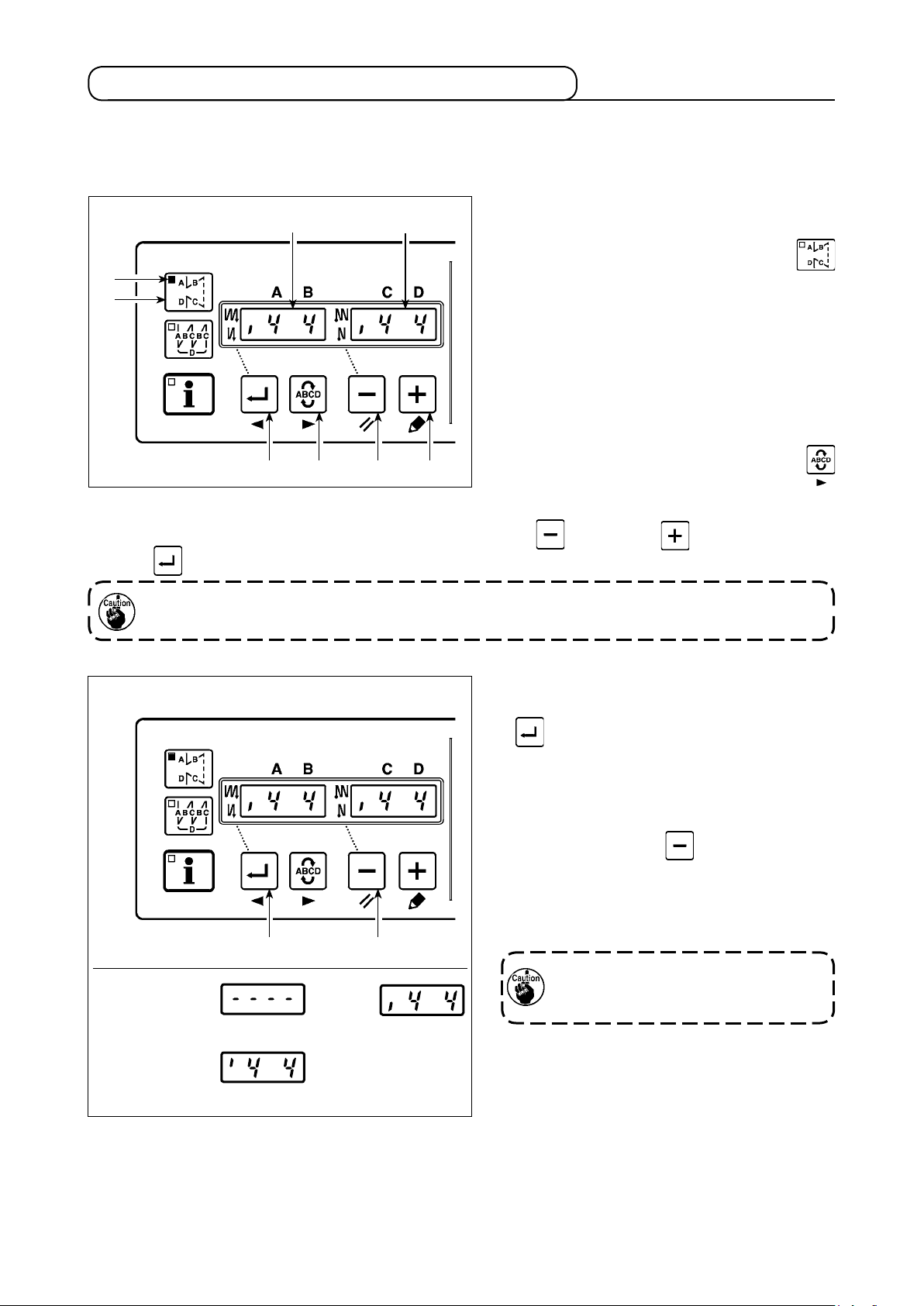

6. SEwING pATTERN SETUp BLOCk (LEfT pANEL) ............................. 4

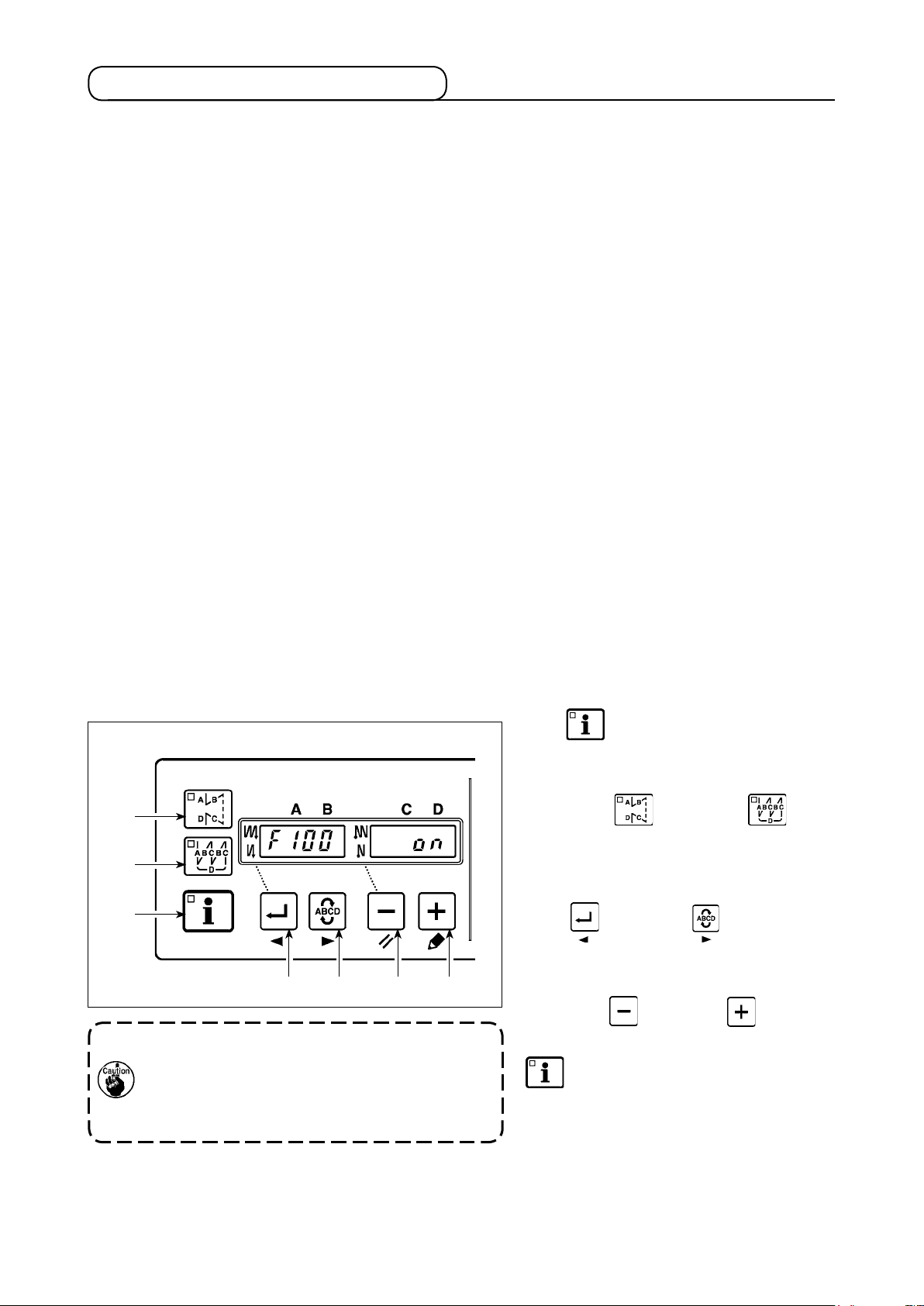

6-1. Conguration.................................................................................................................................4

6-2. Operatingprocedureofthesewingpattern ...............................................................................5

(1) Reverse feed stitching pattern .................................................................................................... 5

(2) Overlapped stitching pattern ....................................................................................................... 6

6-3. One-touchsetting .........................................................................................................................7

6-4. Productionsupportfunction........................................................................................................8

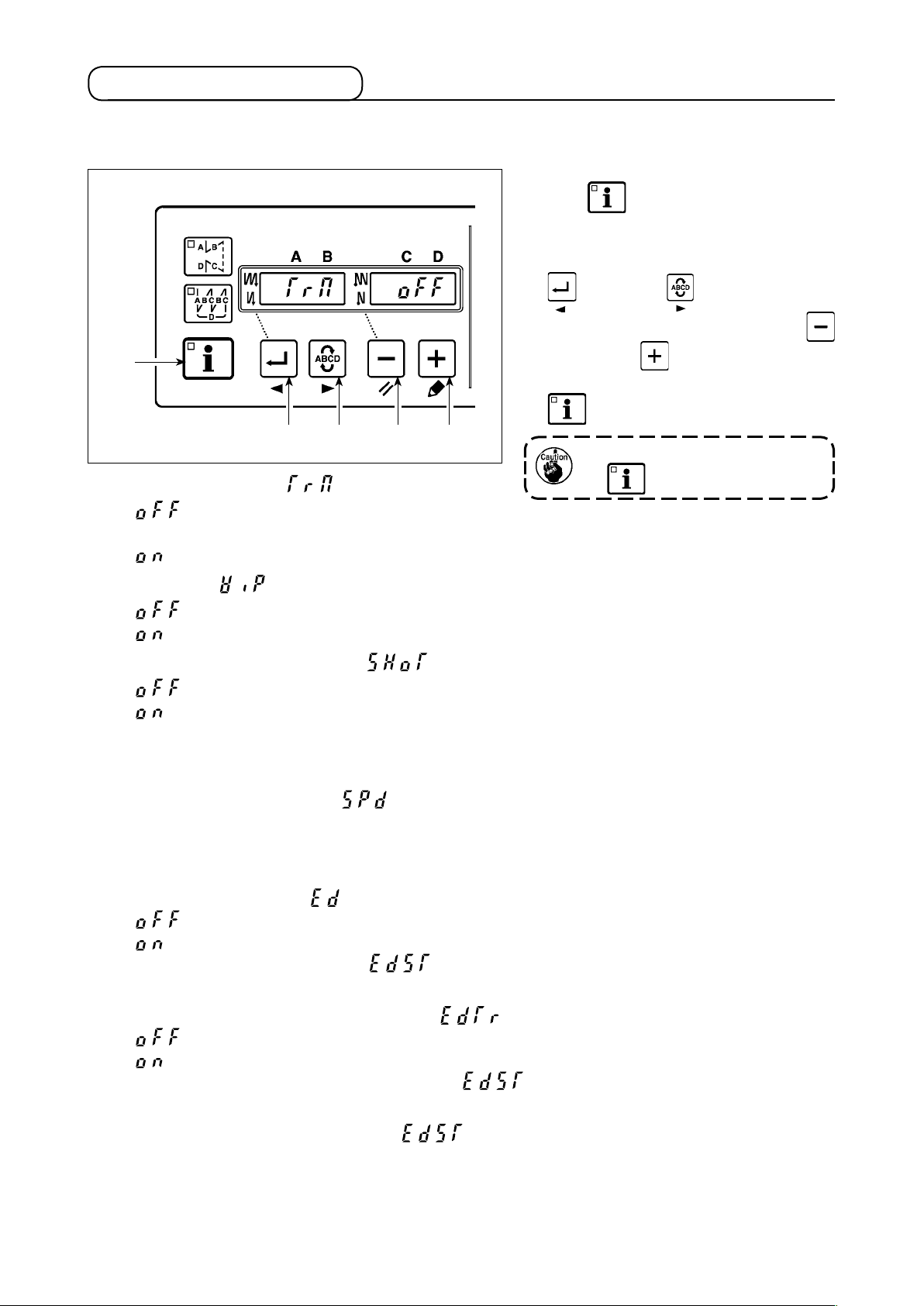

6-5. Settingoffunctions .................................................................................................................... 11

7. pROdUCTION MANAGEMENT dATA MEASUREMENT BLOCk (RIGHT

pANEL) .................................................................................................. 12

7-1. Conguration...............................................................................................................................12

7-2. Normalstartupmode ..................................................................................................................13

(1) Normal startup mode screen..................................................................................................... 14

(2) No. switch input procedure under normal startup mode ...........................................................15

(3) List of No. input patterns by switches........................................................................................16

(4) Outputting measurement data...................................................................................................17

(5) How to change over the shift.....................................................................................................17

7-3. Setupmode..................................................................................................................................18

(1) Setup mode screen ...................................................................................................................18

(2) MAC address check screen ...................................................................................................... 19

(3) Memory switch setup screen.....................................................................................................20

(4) Clock setup screen....................................................................................................................22

(5) Initialization screen....................................................................................................................23

(6) USB format screen.................................................................................................................... 24

(7) IP address setup screen............................................................................................................ 25

(8) Version check screen ................................................................................................................26

7-4. Softwarerewritemode................................................................................................................27

8. AUTOMATIC COMpENSATION Of NEUTRAL pOINT Of THE pEdAL

SENSOR ................................................................................................ 28

9. SELECTION Of THE pEdAL SpECIfICATIONS ................................ 28

10. SETTING Of THE AUTO LIfTER fUNCTION ..................................... 29

11. SELECTING pROCEdURE Of THE kEy-LOCk fUNCTION ............. 30

12. INITIALIzATION Of THE SETTING dATA ........................................... 30

13. ERROR INdICATION............................................................................. 31