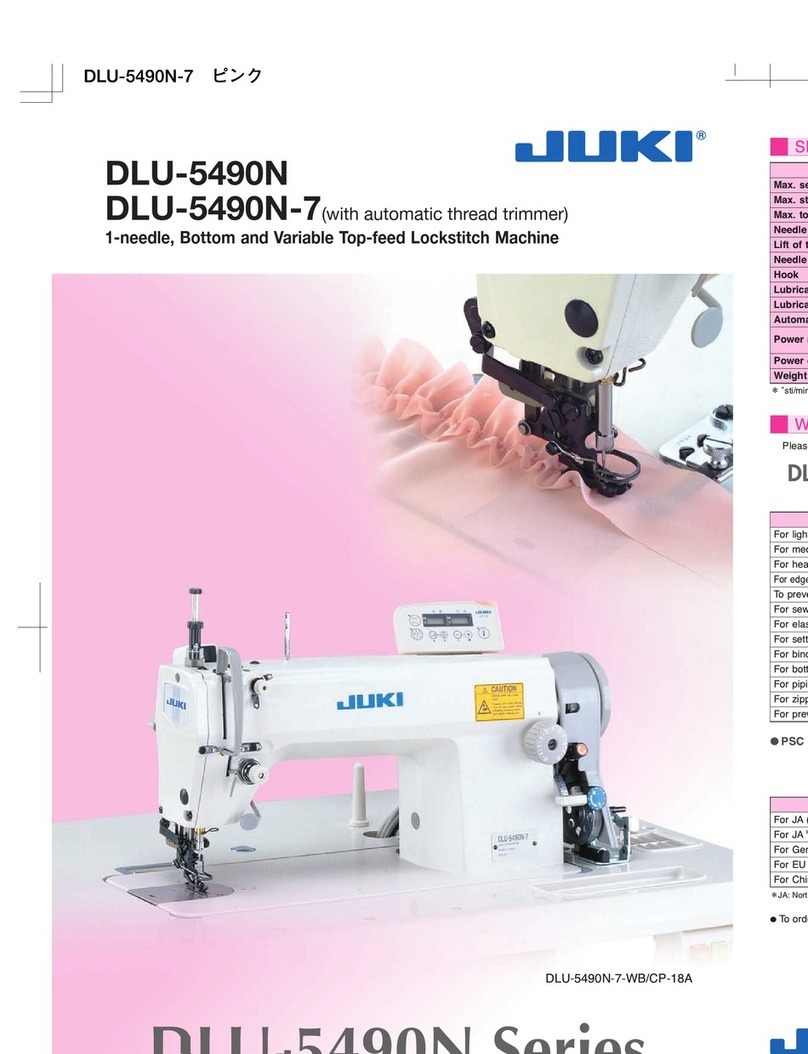

●The machine comes with a direct-drive type motor. As a result, the

machine quickly starts and promises an upgraded stopping accuracy and

excellent responsiveness.

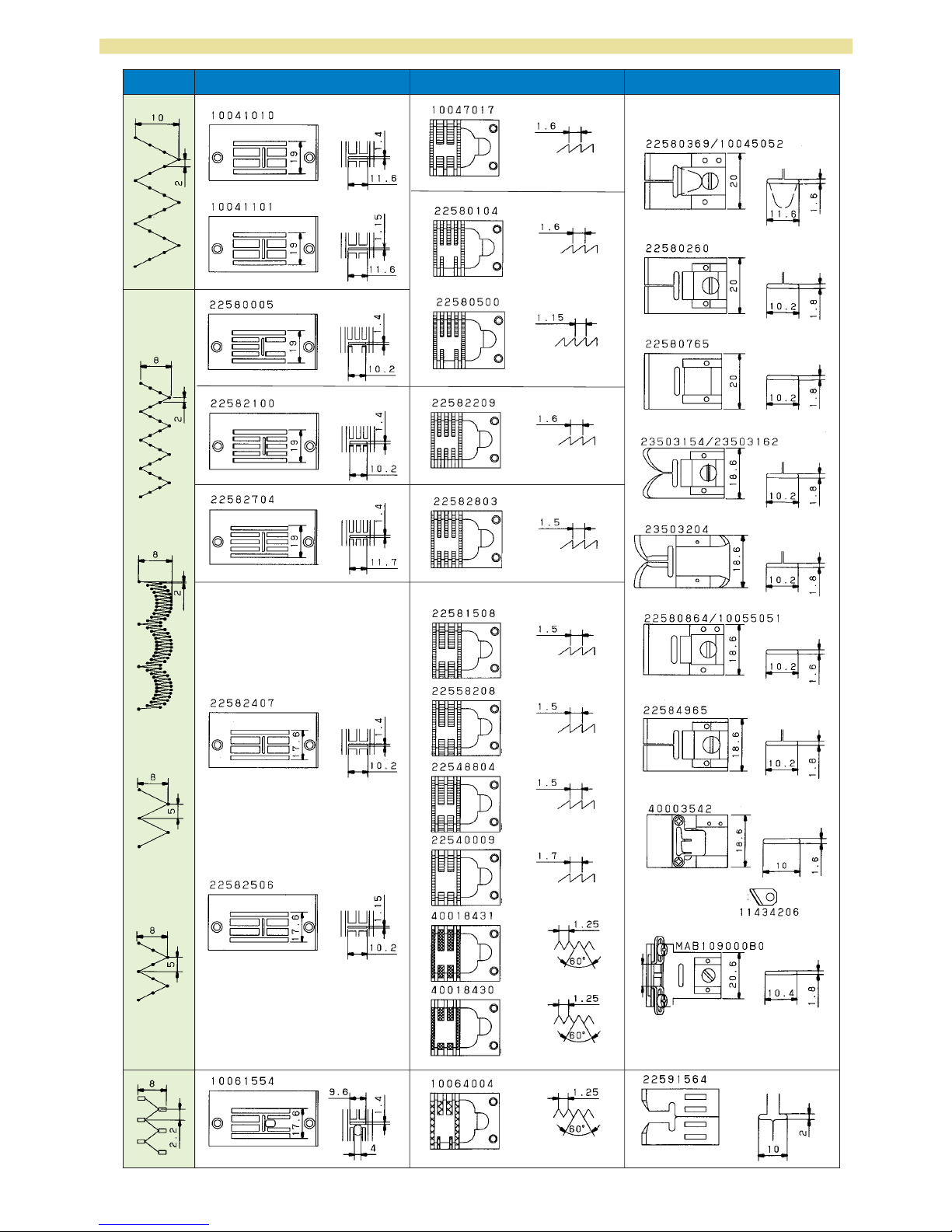

●The arm of the machine head is longer than a normal arm by one size,

offering a longer distance from machine arm to needle to facilitate

handling of the sewing material on the machine, leading to improved

workability.

●Thread trimming mechanism notable for its simple structure and extremely

reliable performance. The knife-sliding method employed by the thread

trimmer guarantees that the thread is cut regardless of the needle throw

position.

●The machine is provided as standard with a micro-lifter screw. This helps

prevent material slippage or damages when using elastic materials.

●Since the hook and needle bar is lubricated with a minute-quantity of

lubricating oil, sewing products are rarely stained with oil.

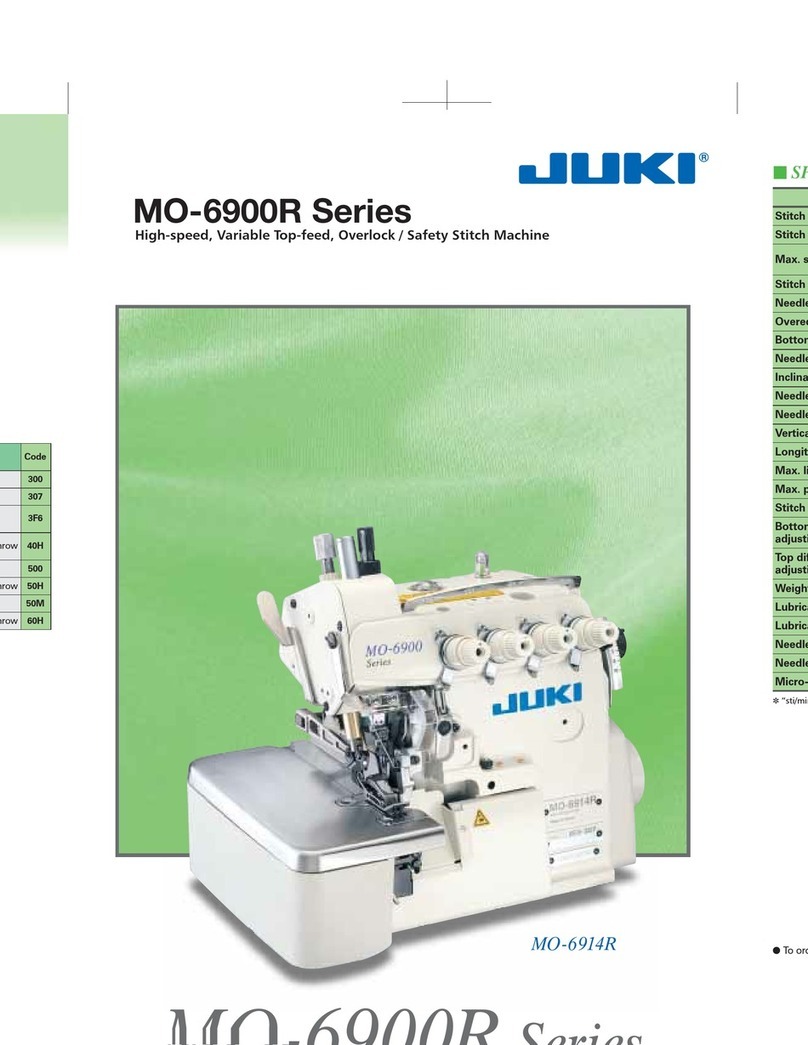

●The zigzag width and feed amount are stored on a stitch-shape

basis. It is therefore not necessary, after changing the stitch

shape, to re-adjust it. For a custom pattern, data can be

programmed on a stitch-by-stitch basis.

●The magnet operating noise is virtually silent, even at the

time of changing over the sewing direction between normal

and reverse feed directions. This contributes to the

achievement of a comfortable working environment with little

noise.

●The feed mechanism is controlled with a stepping motor to enable

continuous sewing at a high speed. The machine achieves the

world's highest sewing speed of 4,000rpm even when performing

pattern sewing, including T-shape stitching and condensation

stitching, dramatically increasing productivity. In addition, the

machine retains stitching shapes with consistency (the maximum

sewing speed differs depending on the sewing condition).

■Basicfunctionsofthepredecessormodel

havebeenincorporatedintothismachine.

■Options

1

1

2

2

■

Newlydevelopedfeedmechanism

isemployed.

■

Themachinehelpstoachieve

acomfortableworkingenvironment.

■

Shape-tackingpatternscanbechanged

withease.

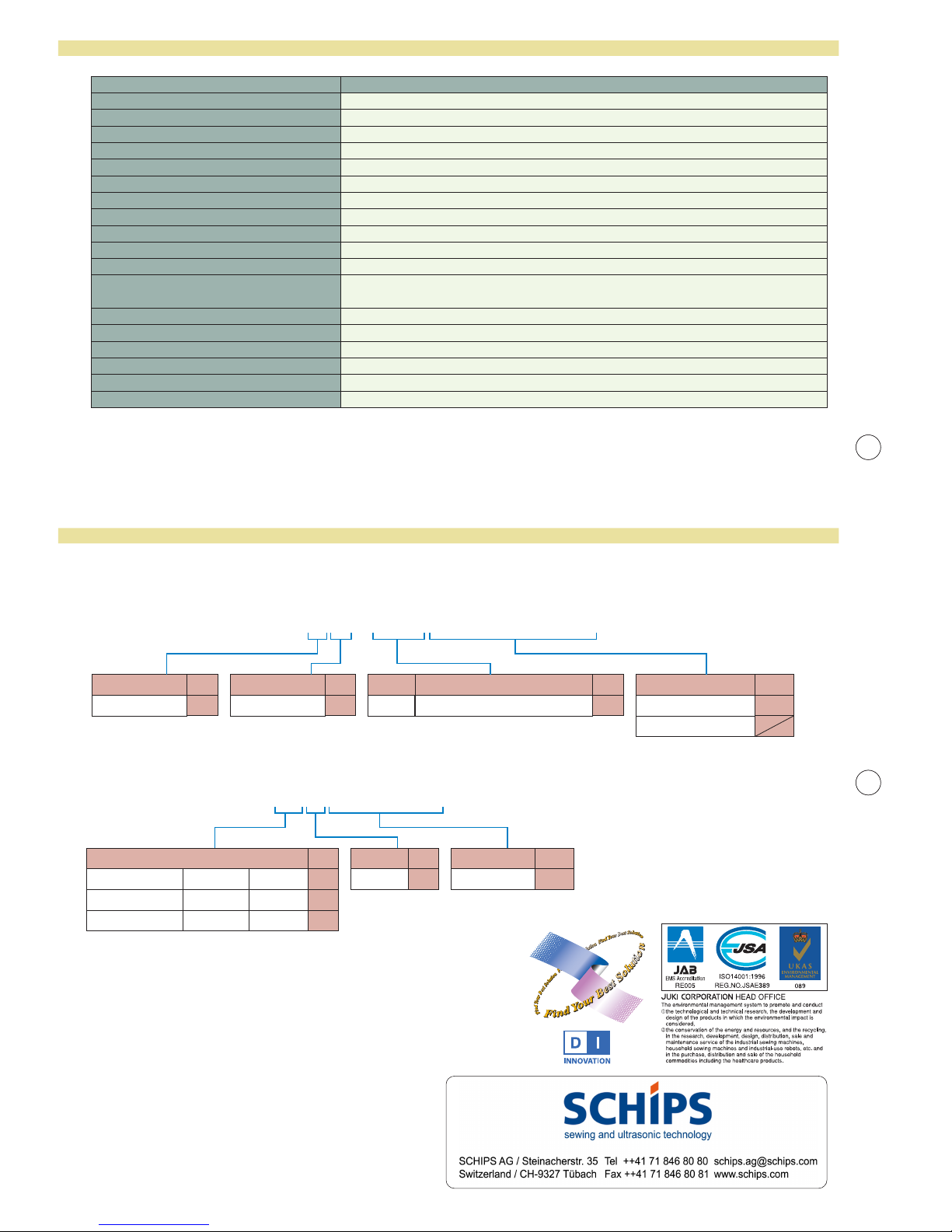

Model FeaturesDescriptionPart No.

− 400-03640 Optional switch kit

AK121 GAK-A21000B0 Auto-lifter (pedal-driven) −

−

This handy switch is used to control various functions*. It is

most effective when operating the machine in a standing

position. (*Needle up/down correction, 1-stitch correction, reverse-

stitch correction, auto lifter and thread trimmer, etc.)

The amount of tape to be fed can be adjusted in accordance

with the sewing speed of the machine. It is adaptable to

processes for attaching reinforcement tape, attaching elastic

tape or lace to foundation.

Applies tension to desired portions of the tape fed from a

tension-free tape puller. The device is started/stopped by

operating the knee switch. This increases operator

productivity without interrupting the sewing work.

The aforementioned parts are used when a lockstitching type

presser foot is installed on the machine.

D1501-583-H00

D1502-583-H00

B1551-586-000

−

−

−

SS-7090910-SP

225-26560

V059 MAV-059000AA

S189A MAS-189000AA

S189B MAS-189000AB

−

−

−

40017095

22591564

10064004

10061554

MAM09700BA0

SS5110710SP

HX005750000

Presser bar

Presser connecting rod

Presser foot connecting foot

Screw

Hard-point hook

Tension-free feeder (Tape feeder)

Pneumatic type

Solenoid type

Thread tension disk asm.

Presser foot asm.

Feed dog

Throat plate asm.

Fagoting folder asm.

Screw

SmartMedia card 16MB

Presser foot connecting

components

(Replaceable presser bar)

Presser foot connecting

components

Elastic tape tensing

device

Dual disks

Gauge set for fagoting

The blade point of this hook prevents abrasion.