CONTENTS

1. SPECIFICATIONS ............................................................................................. 1

2. STITCHES OF PIN-POINT SADDLE STITCHING ............................................ 2

3. CAUTIONS ON SEWING .................................................................................. 2

4. CORNER STITCHING ....................................................................................... 2

5. STANDARD ADJUSTMENT ............................................................................. 3

(1) Adjusting the position of the feed dog.......................................................................... 3

1) Adjusting the longitudinal position ............................................................................................................ 3

2) Adjusting the lateral position..................................................................................................................... 3

3) Adjusting the inclination ............................................................................................................................ 3

(2) Adjusting the height of the feed dog ............................................................................. 5

(3) Adjusting the vertical movement of the feed................................................................ 5

(4) Feed cam timing .............................................................................................................. 7

(5) Height of the needle bar.................................................................................................. 9

(6) Looper crank timing ........................................................................................................ 9

(7) Position of the loop guide............................................................................................. 11

(8) Adjusting the needle and the looper............................................................................ 11

(9) Adjusting the stroke of the spreader........................................................................... 13

(10) Adjusting the needle and the spreader ..................................................................... 13

(11) Timing of relationship among the needle, looper and spreader............................. 15

(12) Adjusting the spreader timing.................................................................................... 15

(13) Adjusting the backlash of the spreader gear............................................................ 17

(14) Adjuting the height of the spreader........................................................................... 17

(15) Position of the looper link eccentric pin ................................................................... 19

(16) Adjusting the thread take-up thread guide ............................................................... 19

(17) Adjustment to adapt to the overlapped section of the heavy-weight materials.... 21

(18) Replacing the needle bar crank (optional component)............................................ 23

6. MOTOR PULLEY AND V BELT ...................................................................... 25

7. CONSUMABLE PARTS AND SELECTIVE PARTS ....................................... 25

8. TROUBLES AND CORRECTIVE MEASURES............................................... 27

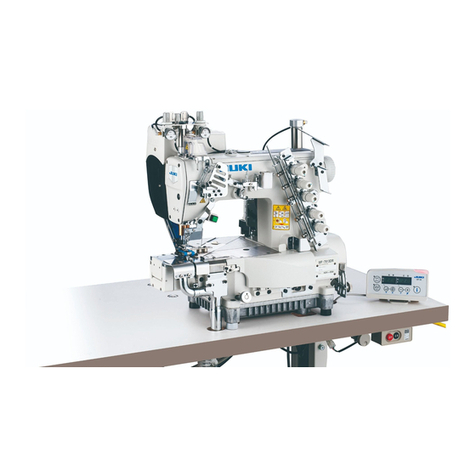

9. DRAWING OF THE TABLE ............................................................................30