i

CONTENTS

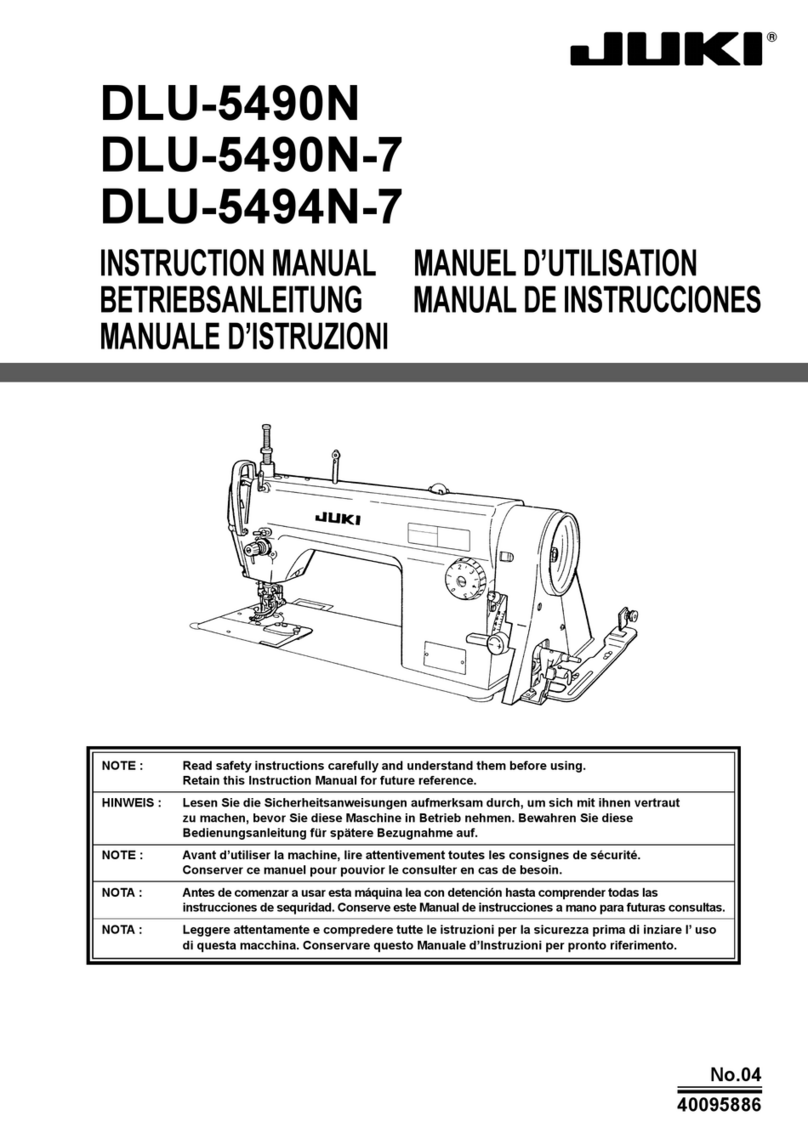

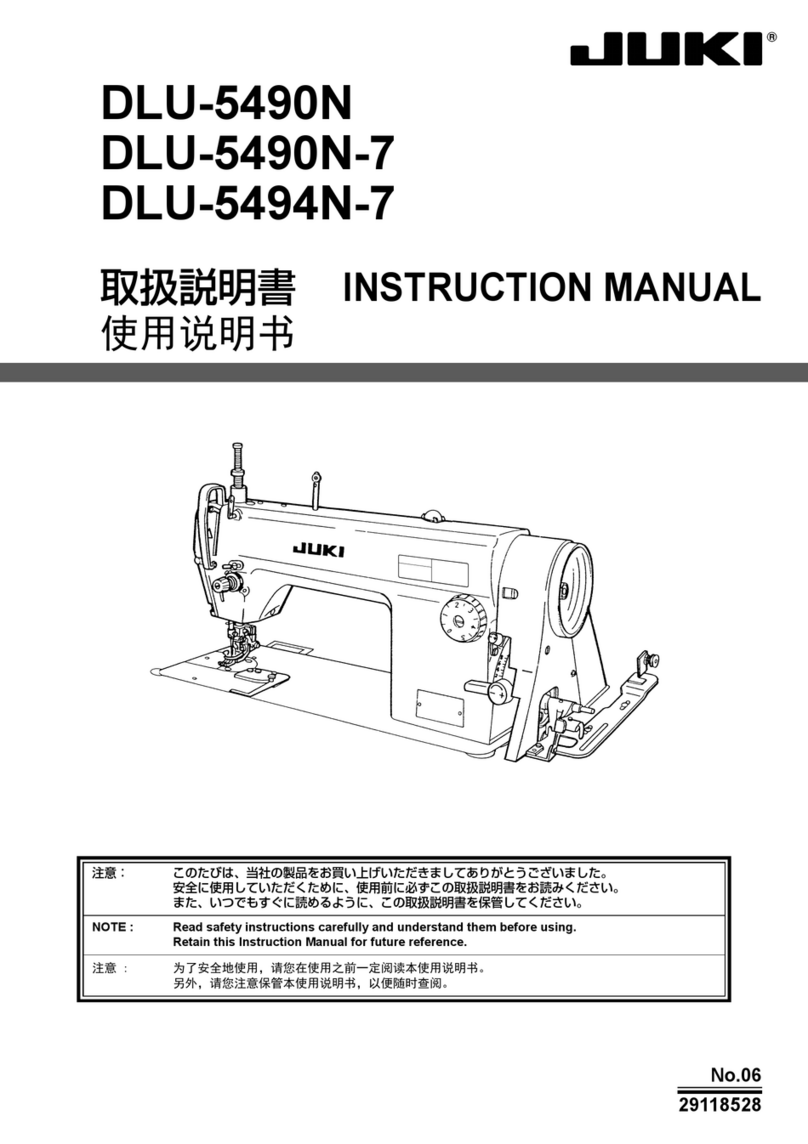

I. SPECIFICATIONS........................................................................................ 1

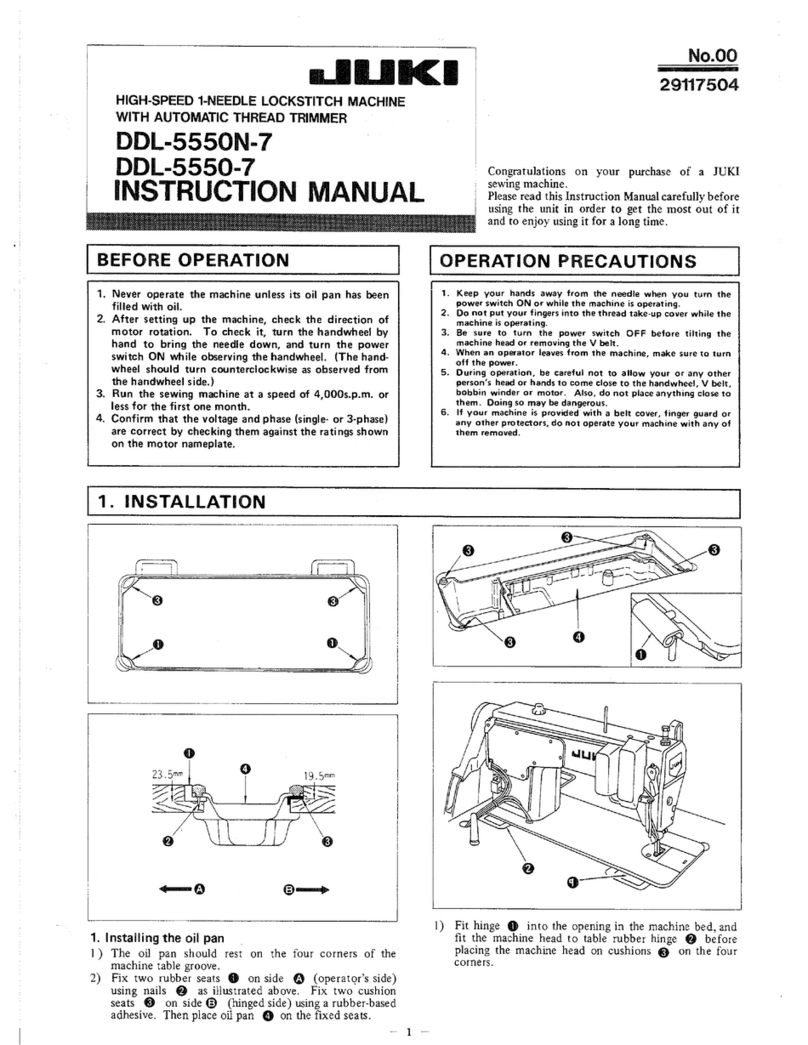

II. SET-UP........................................................................................................ 3

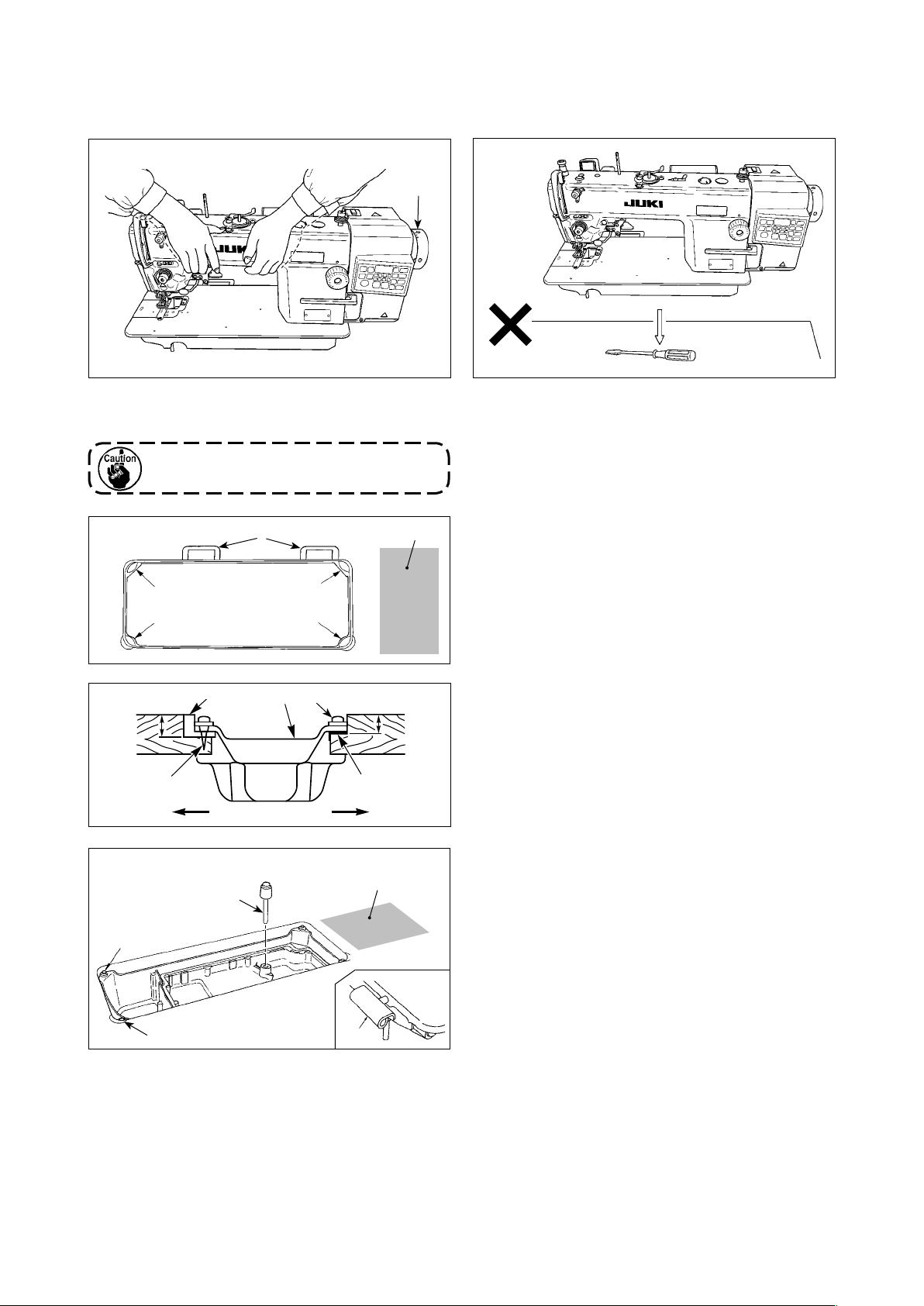

1. Installation .......................................................................................................................... 3

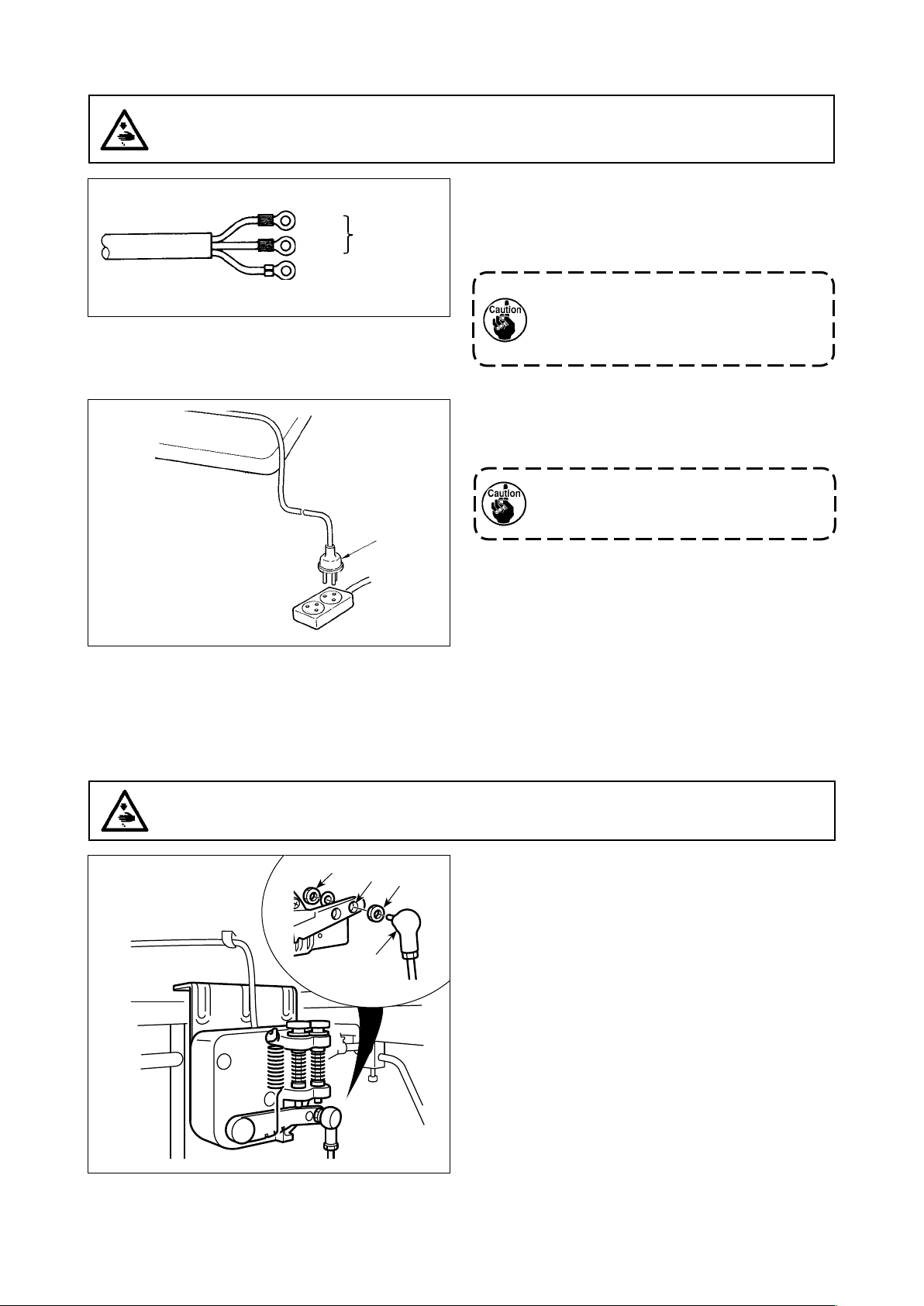

2. Installing the pedal sensor................................................................................................ 4

3. Installing the power switch (for CE)................................................................................. 5

4. Connecting the connector ................................................................................................ 6

5. How to install the power plug ........................................................................................... 7

6. Attaching the connecting rod ........................................................................................... 7

7. Winding the bobbin thread ............................................................................................... 8

8. Installing the cloth chip guide .......................................................................................... 9

9. Adjusting the height of the knee lifter.............................................................................. 9

10. Installing the thread stand.............................................................................................. 10

11. Lubrication ....................................................................................................................... 10

12. Adjusting the amount of oil (oil splashes) .................................................................... 11

13. Attaching the needle ....................................................................................................... 13

14. Setting the bobbin into the bobbin case ....................................................................... 14

15. Adjusting the stitch length ............................................................................................. 14

16. Presser foot pressure...................................................................................................... 14

17. Hand lifter......................................................................................................................... 14

18. Adjusting the height of the presser bar......................................................................... 15

19. Threading the machine head.......................................................................................... 15

20. Thread tension................................................................................................................. 16

21. Thread take-up spring..................................................................................................... 16

22. Adjusting the thread take-up stroke .............................................................................. 16

23. Needle-to-hook relationship ........................................................................................... 17

24. Height of the feed dog..................................................................................................... 17

25. Tilt of the feed dog........................................................................................................... 18

26. Adjusting the feed timing................................................................................................ 18

27. Trimmer............................................................................................................................. 19

28. Adjusting the initial position of the moving knife ........................................................ 21

29.

Replacing the counter knife .............................................................................................21

30. Adjusting the counter knife pressure ............................................................................ 22

31. Changing the moving knife............................................................................................. 22

32. One-touch type manual reverse feed stitching ............................................................ 23

33. Wiper................................................................................................................................. 23

34. Other replaceable parts................................................................................................... 24

35. Installing the gauge......................................................................................................... 25

36. Pedal pressure and pedal stroke ................................................................................... 25

37. Adjustment of the pedal.................................................................................................. 26

38. Marker dots on the handwheel....................................................................................... 26