●Ample storage capacity: maximum of 360,000 stitches on one floppy disk and 691 patterns

on a hard disk.

An EEP-ROM may be used.

●A maximum of 20,000 stitches can be input per pattern. With this large storage capacity, the

machine supports embroidery patterns with large numbers of stitches.

●Functions that are frequently used in programming works such as normal sewing (linear

sewing and spline sewing), point sewing, jumping, and thread trimming can be allocated to

specific keys mounted on the operation panel. The use of these keys reduces the time

required for data entry.

[Major input functions]

●Creation of linear, spline, arc, and circular stitches.

●Creation of various kinds of zigzag stitches, offset stitches, double-forward stitches, double-

reverse stitches, automatic back-tuck, condensation stitches, overlapping stitches, etc.

●Arrangement of move, copy, erase, and symmetry functions.

●Mechanical command to actuate the tension controller No. 3, changes in jump speed,

changes in sewing speed, etc.

●Data can be input using function numbers.

LK-1930 (Table stand is optionally available.)

Higher lift of the presser foot

The machine head is designed for improved

operability.

The feeding frame type can be selected to match the use

of the machine in your work.

Upgraded responsiveness, low vibration, and low noise

create a comfortable workplace.

With an increased maximum

lift of the feeding frame

(22mm for the magnet-driven

feeding frame and 25mm for

the pneumatic-driven feeding

frame), the machine ensures

easy placement of heavy-

weight materials.

●The hand pulley is located at

the machine arm unit to

allow the operator to visually

check the needle entry and

needle-to-hook timing with

ease.

●The machine is provided with

a needle bar reverse rotating

function. This permits the

machine to stop with the

needle rested at the highest

dead point to allow a heavy-

weight material to be placed

on the machine easily.

Two different feeding frame

types are prepared; the

monolithic type (magnet-driven)

and the separately driven type

(pneumatic-driven). Select the

type which best suits your work

and the machine application.

With the monolithic type you can

lift/lower the feeding frame using

a manual pedal*by controlling

the pedal pressure.

*

The manual pedal is optionally

available.

With its direct-drive machine

head (with no belt) directly

joined to a compact AC

servomotor, the machine

provides improved

responsiveness and upgraded

stop accuracy. Vibration and

noise are reduced even during

high-speed operation, thereby

achieving a comfortable working

environment.

22mm

LK-1920SA

(Pneumatic sepalately driven

feeding frame)

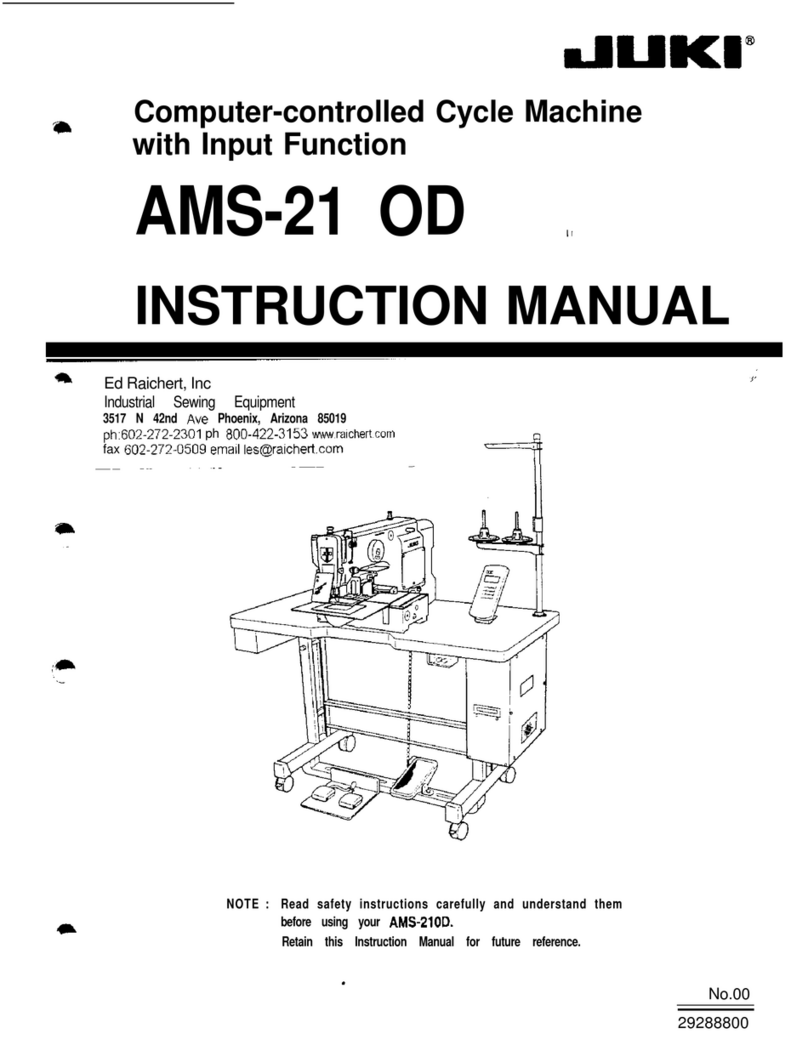

The LK-1930 is provided with an input function equivalent

to that equipped in the AMS-210D computer-controlled

cycle machine. With its larger storage capacity, the

machine supports diversified sewing patterns. In addition,

the sewing machine functions and patterns can be input

through the operation panel.

Abundant input functions enable the machine to respond

to the sewing requirements of all sewing patterns.

●With its automatic correction feature, the machine can

enlarge/reduce patterns without deforming them.

EXCELLENT OPERABILITY

LK-1930 (PROVIDED WITH AN INTERMEDIATE PRESSER AND INPUT FUNCTION)