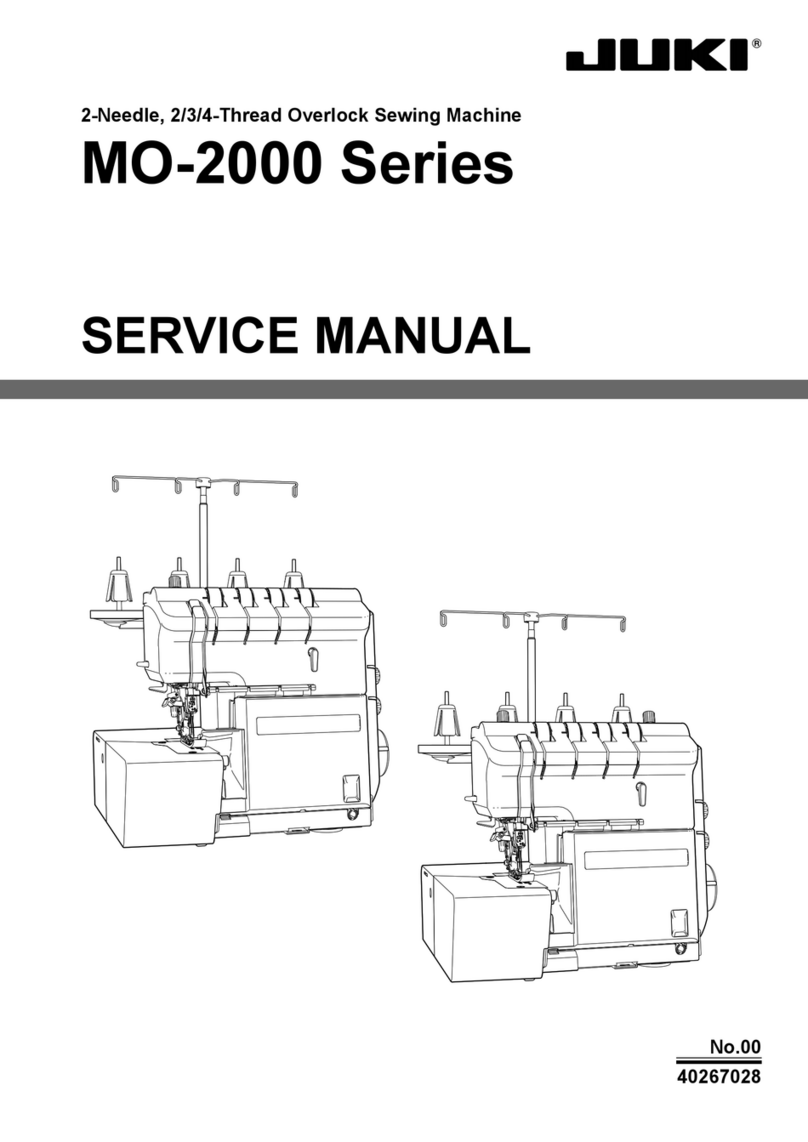

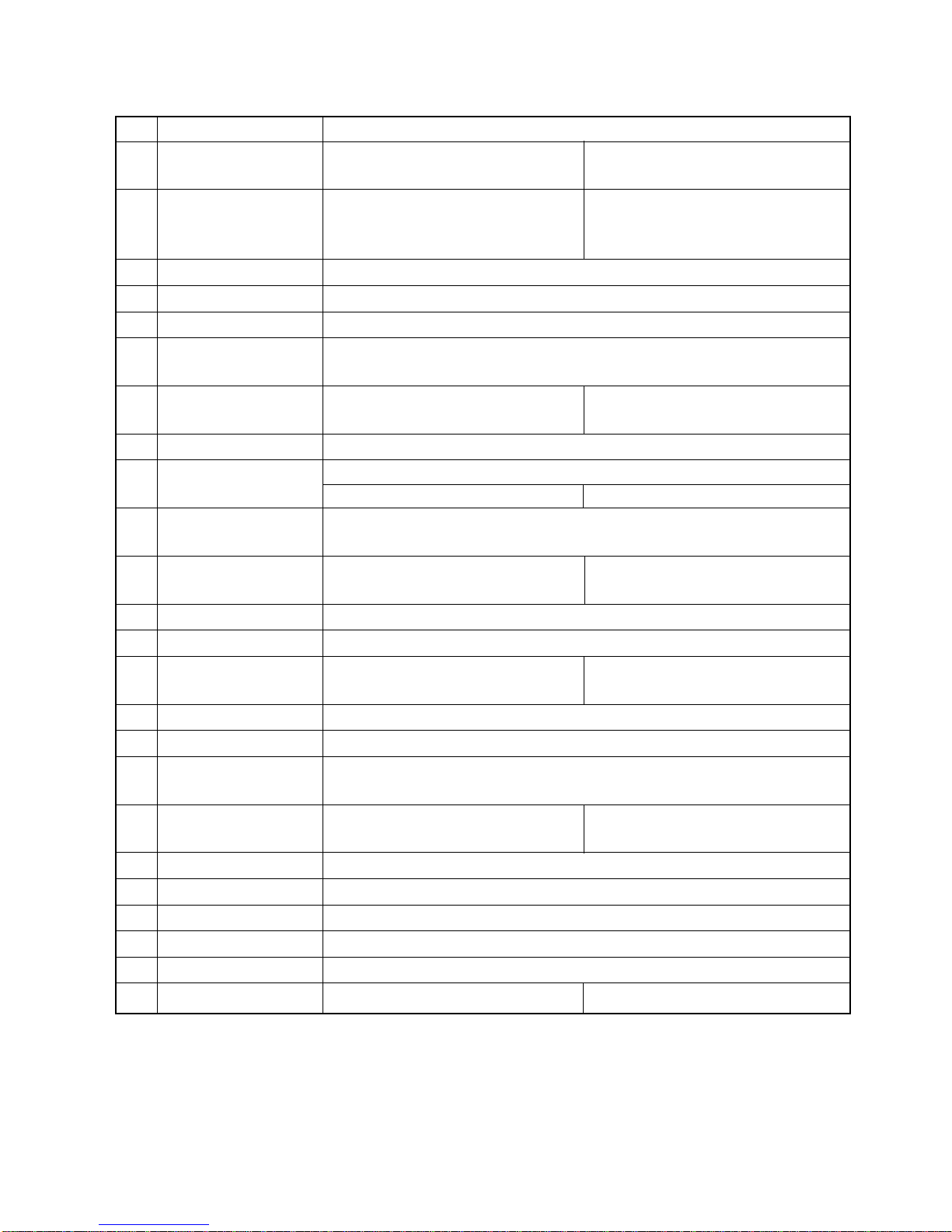

CONTENTS

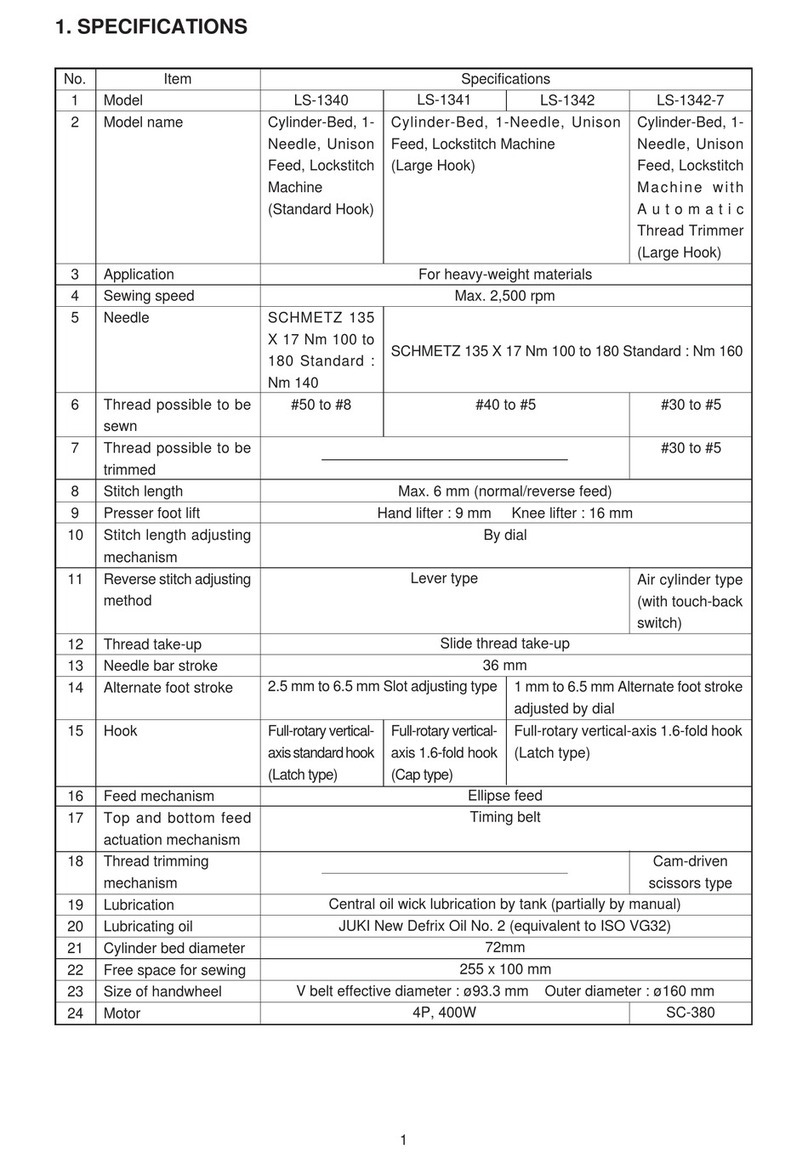

1. SPECIFICATIONS.......................................................................................... 1

2. STANDARD ADJUSTMENT ...........................................................................8

(1) Needle entry position.................................................................................................8

(2) Longitudinal position of the feed dog ......................................................................8

(3) Lateral position of the feed dog..............................................................................10

(4) Height of the feed dog .............................................................................................10

(5) Height of the hook....................................................................................................12

(6) Adjusting the inner hook guide ..............................................................................12

(7) Needle-to-hook timing .............................................................................................14

(8) Lift of the presser foot .............................................................................................16

1) Hand lifter .........................................................................................................................................16

2) Knee lifter (Without thread trimmer only) ..........................................................................................16

3) Automatic presser foot lifter (Machine with thread trimmer only)......................................................18

(9) Timing between the upper shaft and the lower shaft............................................18

(10) Feed cam timing .......................................................................................................20

1) Horizontal feed cam timing ...............................................................................................................20

2) Top feed cam timing..........................................................................................................................22

(11) Feed motion ..............................................................................................................24

1) Amount of alternate vertical movement (position of the vertical adjusting arm) ...............................24

2) Alternate momentum ........................................................................................................................26

(12) Needle sway (Adjusting the bottom feed amount)................................................26

(13) Stitch length of forward/reverse feed .....................................................................28

(14) Balancer (Machine without thread trimmer only) ..................................................28

(15) Vertical position of the needle bar rocking frame .................................................30

(16) Dimension of the needle stop adjusting slide shaft (asm.) ..................................32

(17) Position of the change lever....................................................................................32

(18) Position of the reverse feed control lever..............................................................34

(19) Safety clutch .............................................................................................................34

(20) Reverse feed cylinder ..............................................................................................36

(21) Lubrication ................................................................................................................36

1) In case of manual lubrication ............................................................................................................36

2) In case of automatic lubrication ........................................................................................................38

(22) Thread trimmer device .............................................................................................40

1) Position of the counter knife and the clamp spring ...........................................................................40

2) Position of the counter knife base.....................................................................................................42

3) Vertical position of the moving knife .................................................................................................42

4) Adjusting the knife pressure .............................................................................................................44

5) Thread trimmer cam .........................................................................................................................44

6) Thread trimmer cam timing...............................................................................................................46

7) Connecting the rocking arm and the thread trimmer roller arm ........................................................46

8) Connecting the left and right rocking arms (2-needle machine only) ..............................................48

9) Thread trimmer solenoid...................................................................................................................48

(23) Alternate vertical dial ...............................................................................................50

1) Installing position of the detection switch of the amount of alternate vertical movement .................50