ii

3-2. Attaching and removing the bobbin .......................................................................................26

3-3. Threading the hook ..................................................................................................................27

3-4. Winding a bobbin .....................................................................................................................27

3-5. Threading the machine head...................................................................................................29

3-6. Installing the attachment .........................................................................................................30

4. ADJUSTING THE SEWING MACHINE ..............................................................31

4-1. Thread tension..........................................................................................................................31

4-1-1. Adjusting the tension of thread tension controller No. 1................................................ 31

4-1-2. Adjusting the needle thread tension (Active tension)..................................................... 31

4-1-3. Adjusting the bobbin thread tension ................................................................................ 31

4-2. Thread take-up spring..............................................................................................................32

4-2-1. When you want to change the stroke of the thread take-up spring............................... 32

4-2-2. When you want to change the tension of the thread take-up spring............................. 32

4-3. Presser foot (Active presser device) ......................................................................................33

4-3-1. Presser foot pressure......................................................................................................... 33

4-3-2. Micro-lifter function ............................................................................................................33

4-4. Adjusting the stitch length ......................................................................................................34

4-5. Changing the sewing speed....................................................................................................34

4-6. Adjusting the alternating vertical movement amount...........................................................35

4-7. Thread trimming and condensation stitching function ........................................................36

4-8. LED hand light ..........................................................................................................................38

4-9. Reverse feed stitching .............................................................................................................38

4-10. Jog dial....................................................................................................................................38

4-11. Custom switch ........................................................................................................................39

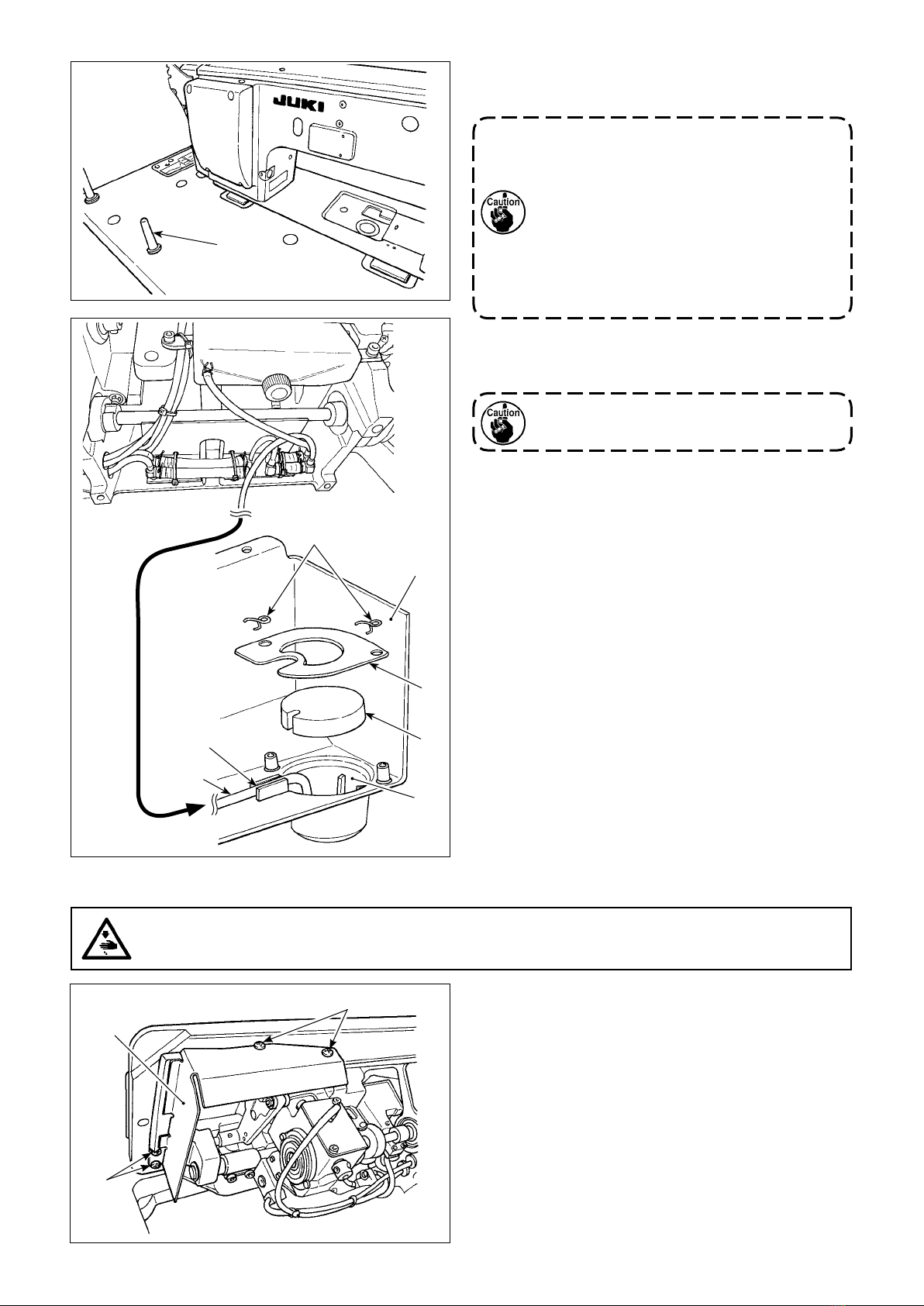

4-12. Adjusting the oil quantity in the hook ..................................................................................42

5. OPERATION OF THE SEWING MACHINE........................................................ 43

5-1. Resetting the safety clutch......................................................................................................43

5-2. Lifting the presser foot at an emergency...............................................................................43

5-3. Power lamp ...............................................................................................................................44

5-4. Knee switch...............................................................................................................................45

6. HOW TO USE THE OPERATION PANEL .......................................................... 46

6-1. Explanation of the sewing screen (when selecting a sewing pattern)................................46

6-2. Sewing patterns........................................................................................................................50

6-2-1. Sewing pattern conguration ............................................................................................50

6-2-2. List of sewing patterns....................................................................................................... 51

6-2-3. Reverse feed stitching (at start) pattern........................................................................... 53

6-2-4. Reverse feed stitching (at end) pattern ............................................................................ 60

6-2-5. Editing the sewing patterns...............................................................................................61

6-2-6. List of pattern functions..................................................................................................... 66

6-2-7. Teaching function ............................................................................................................... 73

6-2-8. One-touch utility changeover function............................................................................. 75

6-2-9. Registration of a new sewing pattern ............................................................................... 76

6-2-10. Copying a pattern .............................................................................................................78

6-2-11. Narrow-down function......................................................................................................79

6-3. Counter function.......................................................................................................................81

6-3-1. Displaying the sewing screen under the counter display mode.................................... 81

6-3-2. Types of the counter........................................................................................................... 81

6-3-3. How to set the counter .......................................................................................................82

6-3-4. How to reset the count-completion state ......................................................................... 85