JUKI HZL-25Z User manual

Other JUKI Sewing Machine manuals

JUKI

JUKI MO-6800S Series User manual

JUKI

JUKI DLD-5430NE Series User manual

JUKI

JUKI PLC-2760NVM User manual

JUKI

JUKI MO-654 User manual

JUKI

JUKI AMS-215D User manual

JUKI

JUKI DLU-5490N User manual

JUKI

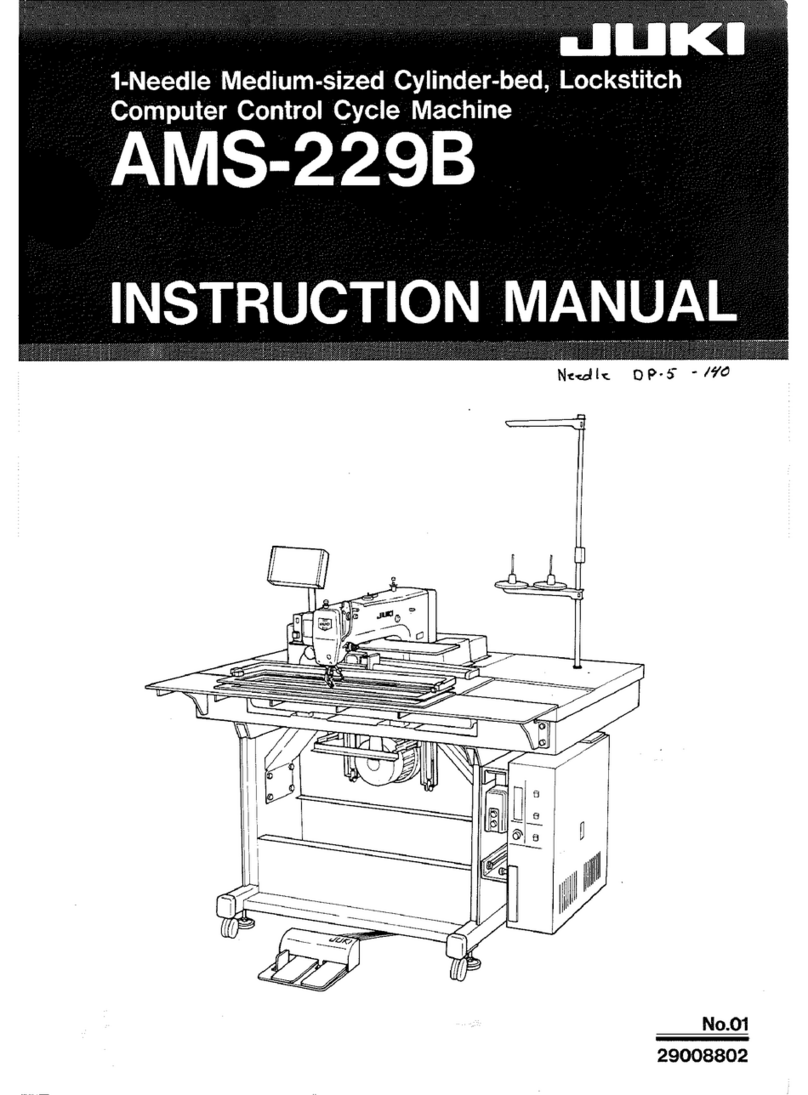

JUKI AMS-229B User manual

JUKI

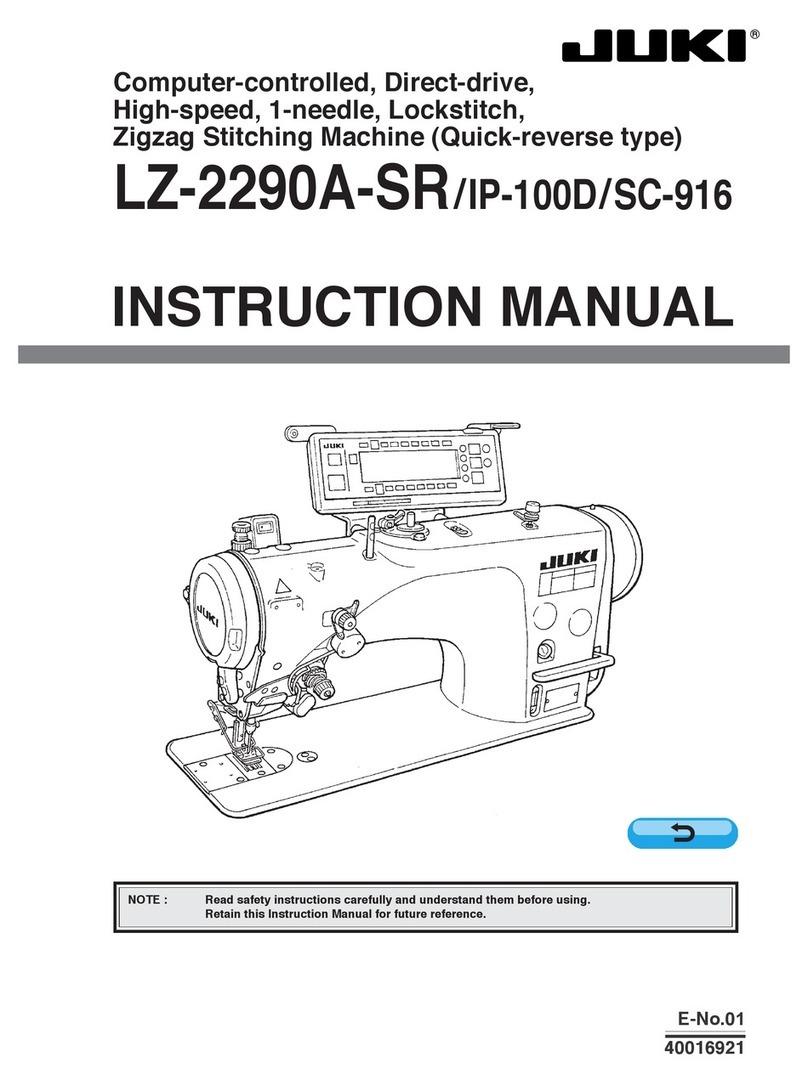

JUKI LZ-2290A-SR/IP-100D/SC-916 User manual

JUKI

JUKI TL-2000Qi User manual

JUKI

JUKI MEB-3810N Series User manual

JUKI

JUKI PL12 User manual

JUKI

JUKI DDL-8700A-7 User manual

JUKI

JUKI L-1 Series User manual

JUKI

JUKI DLU-5494N-7 User manual

JUKI

JUKI PS-800SB-2850 Series User manual

JUKI

JUKI DDL-8700-7 User manual

JUKI

JUKI PLK-J6040R3 User manual

JUKI

JUKI DDL-8300N User manual

JUKI

JUKI MF-7800/UT25 User manual

JUKI

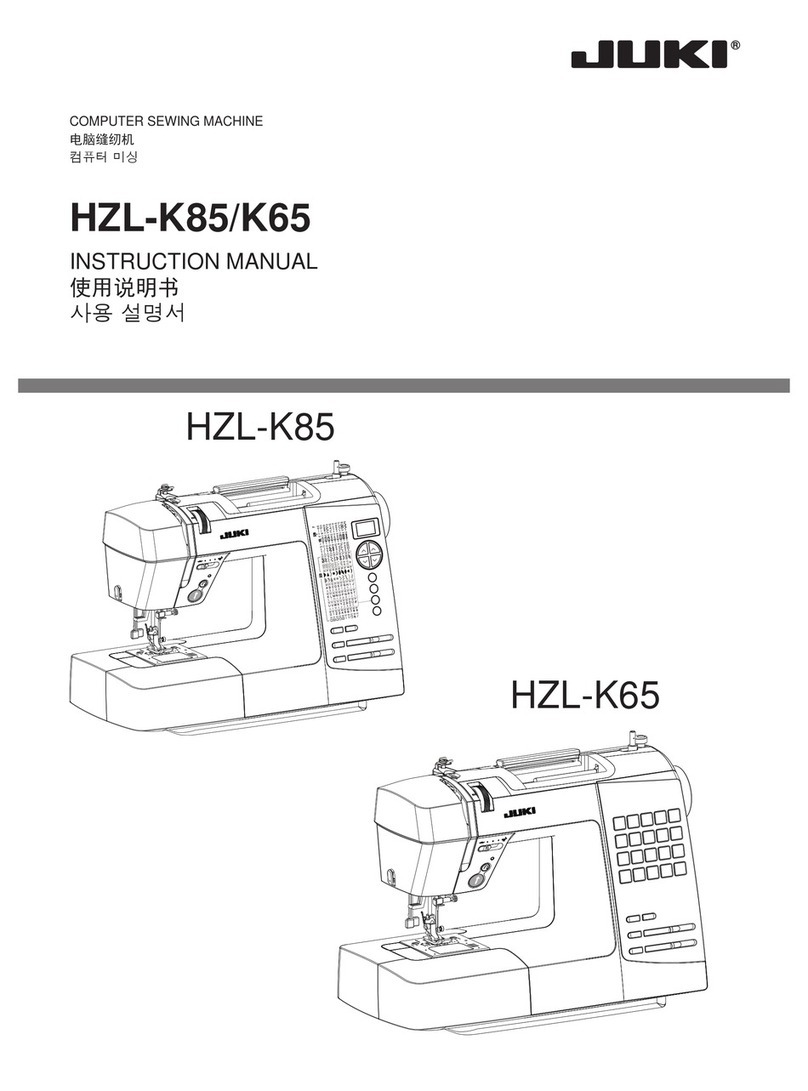

JUKI HZL-K85 User manual