– 1 –

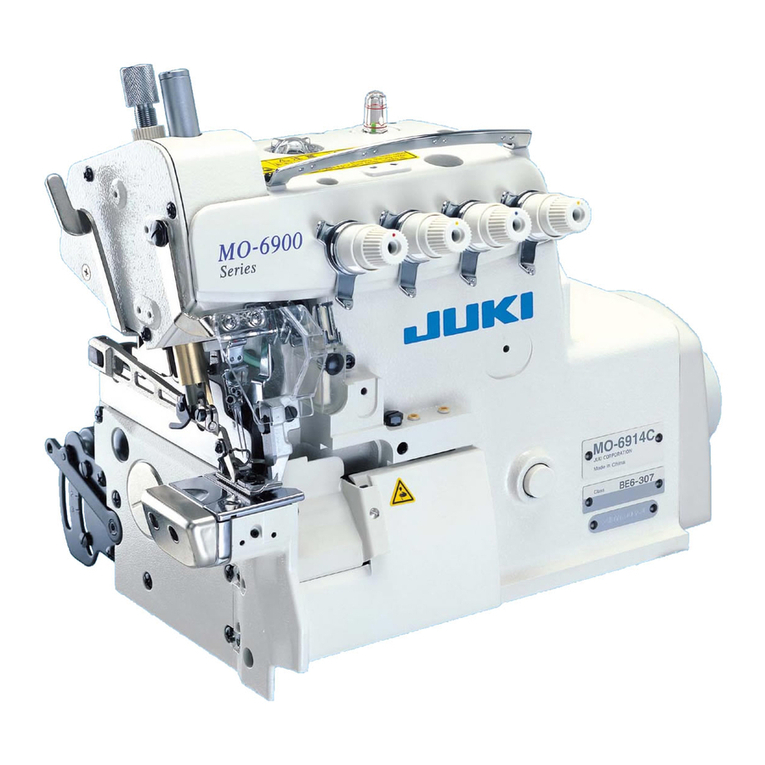

1. Specications

PLC-2760NVMA70BBZ

No. Item Application

1 Model PLC-2760NVM

2 Model name 2-needle, post-bed, unison-feed, lockstitch machine with vertical-axis hook

3 Application Medium- to heavy-weight materials, car seat, furniture

4 Sewing speed Max. 2,500 sti/min

(Refer to "10. SEWING SPEED TABLE" in the Instruction Manual for the standard

model.)

5 Needle Ferd. SCHMETZ 134 - 35 (Nm 100 to Nm 180) (Standard : Nm 140)

6 Applicable thread size for sewing #30 to #5 (Europe 60 / 3-20 / 3)

7 Applicable thread size to be cut #30 to #5 (Europe 60 / 3-20 / 3)

8 Stitch length Max. 12 mm (forward/reverse feed)

However, the machine is shipped with its stitch length restricted to 7 mm.

9 Presser foot lift 20 mm

10 Presser foot pressure control Electric control (driven by a pulse motor)

11 Horizontal feed control Electric control (driven by a pulse motor)

12 Alternate vertical feed control Electric control (driven by a pulse motor)

13 Reverse stitch adjusting method Pulse motor driving (with touch-back switch)

14 Number of patterns Sewing pattern ............................ 99 patterns (For the polygonal shape sewing, as

many as 10 patterns can be registered.)

Cycle sewing pattern ................... 9 patterns

Custom-pitch pattern ................... 20 patterns

Condensation custom pattern ..... 9 patterns

15 Thread take-up Link thread take-up

16 Needle bar stroke 40 mm

17 Amount of the alternate vertical

movement

MAX. 9 mm

However, the machine is shipped with its stitch length restricted to 6.5 mm.

18 Needle thread tension Electric control (driven by a solenoid)

19 Hook Vertical-axis 1.6-fold hook (Latch type)

20 Feed mechanism Box feed

21 Drive system/Top and bottom

vertical axis drive

Main shaft direct drive system/Timing belt

22 Lubrication Automatic lubrication by semi-dry head plunger pump (with oil gauge)

23 Lubricating oil JUKI New Defrix Oil No. 1 (equivalent to ISO standard VG7)

or JUKI MACHINE OIL No. 7

24 Bed size 643 mm × 178 mm

25 Space under the arm 347 mm × 298 mm

26 Hand wheel size Outer diameter : ø123 mm

27 Motor/Control box DD motor : 800W AC servomotor

Control box : SC-952

28 Machine head weight 88 kg

29 Rated power consumption 600 VA

30 Noise - Equivalent continuous emission sound pressure level (LpA) at the

workstation:

A-weighted value of 83.5 dB; (Includes KpA = 2.5 dB); according to ISO

10821- C.6.2 - ISO 11204 GR2 at 2,500 sti/min.

-Sound power level (LWA);

A-weighted value of 90.5 dB; (Includes KWA = 2.5 dB); according to ISO

10821- C.6.2 - ISO 3744 GR2 at 2,500 sti/min.