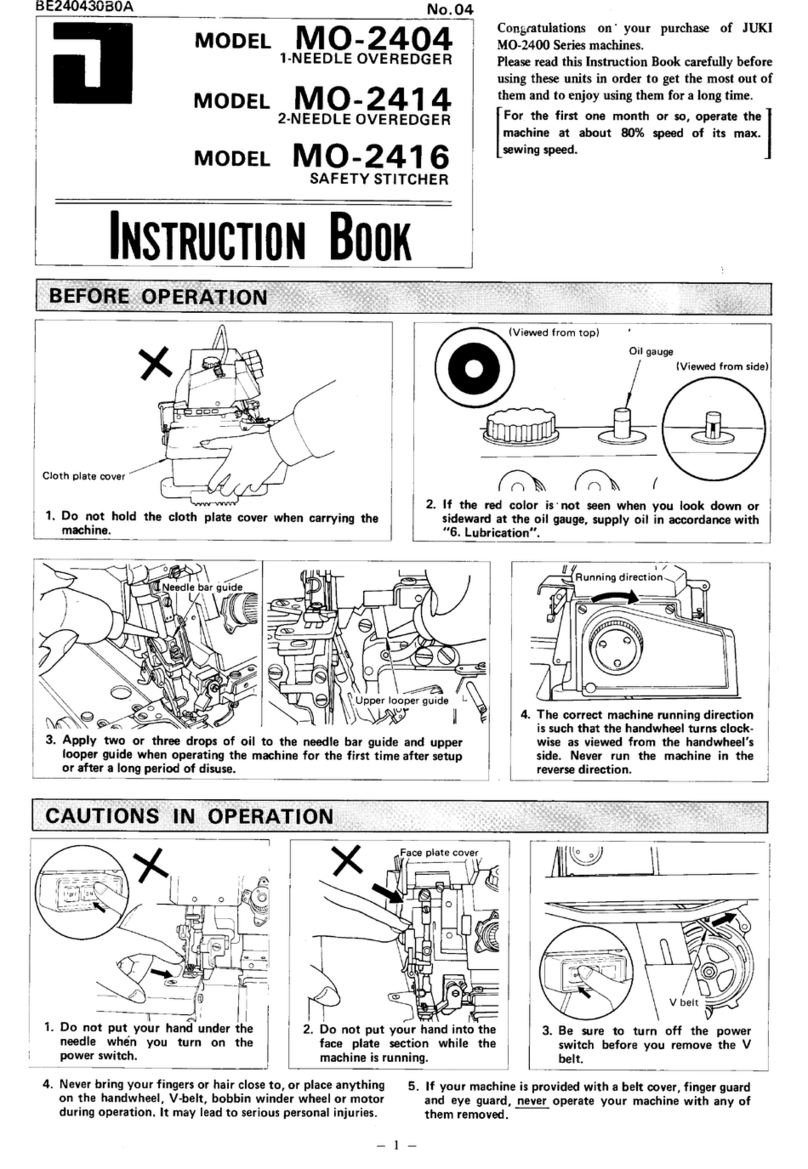

SECTION

PAGE

Adjustment

Without

removal

of parts

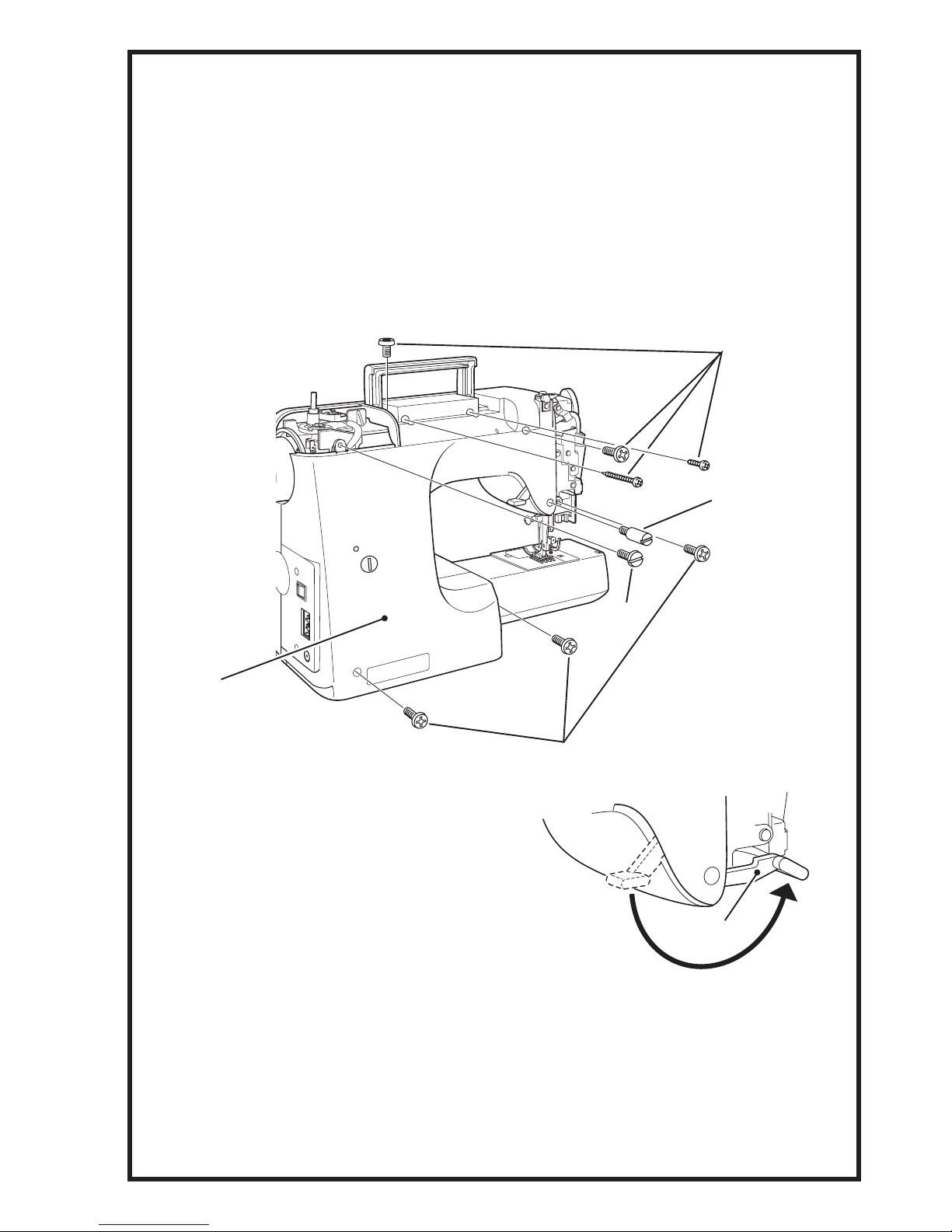

With removal of outer parts

Front

cover

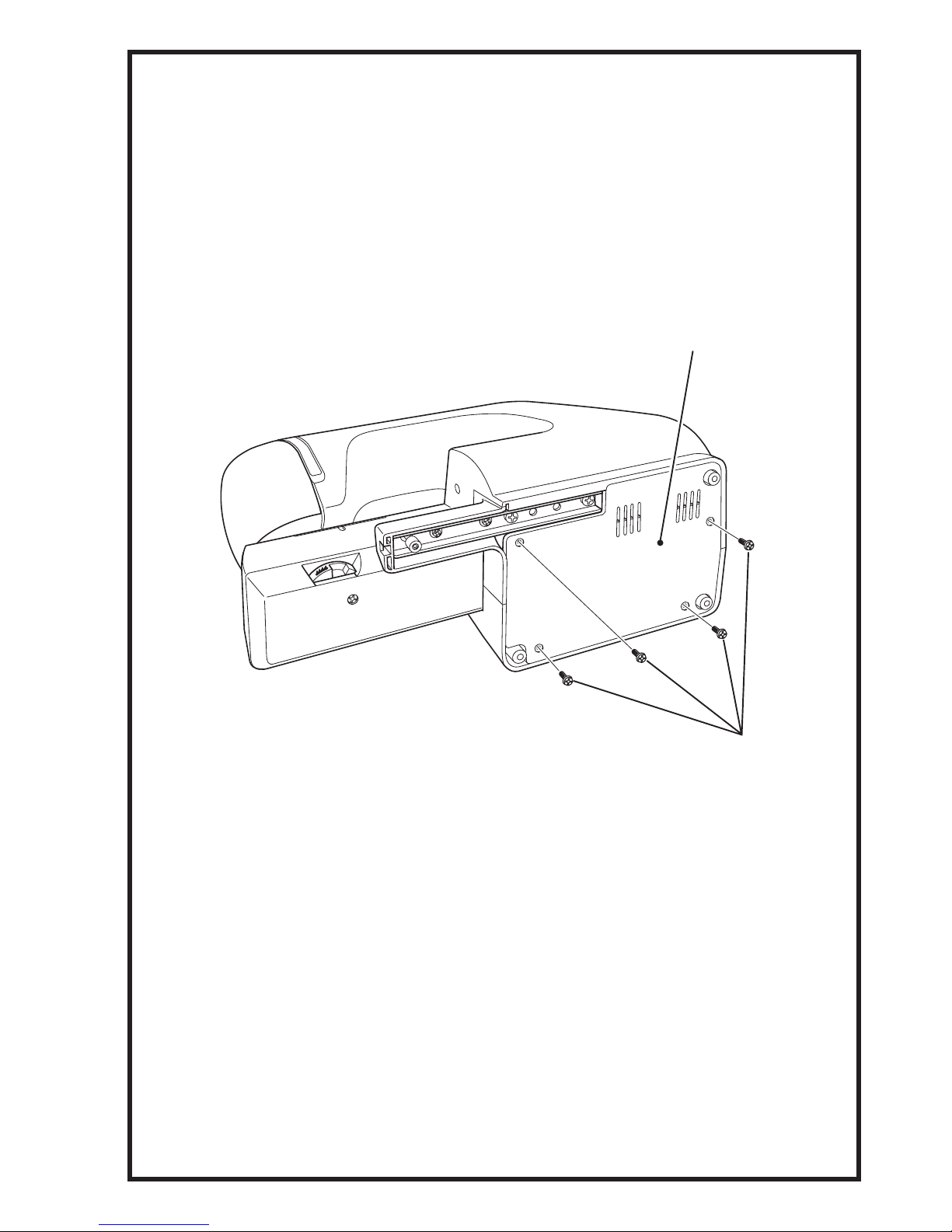

Back

cover

Face

cover

Spool

pin

stand

SV

cover

Needle

plate

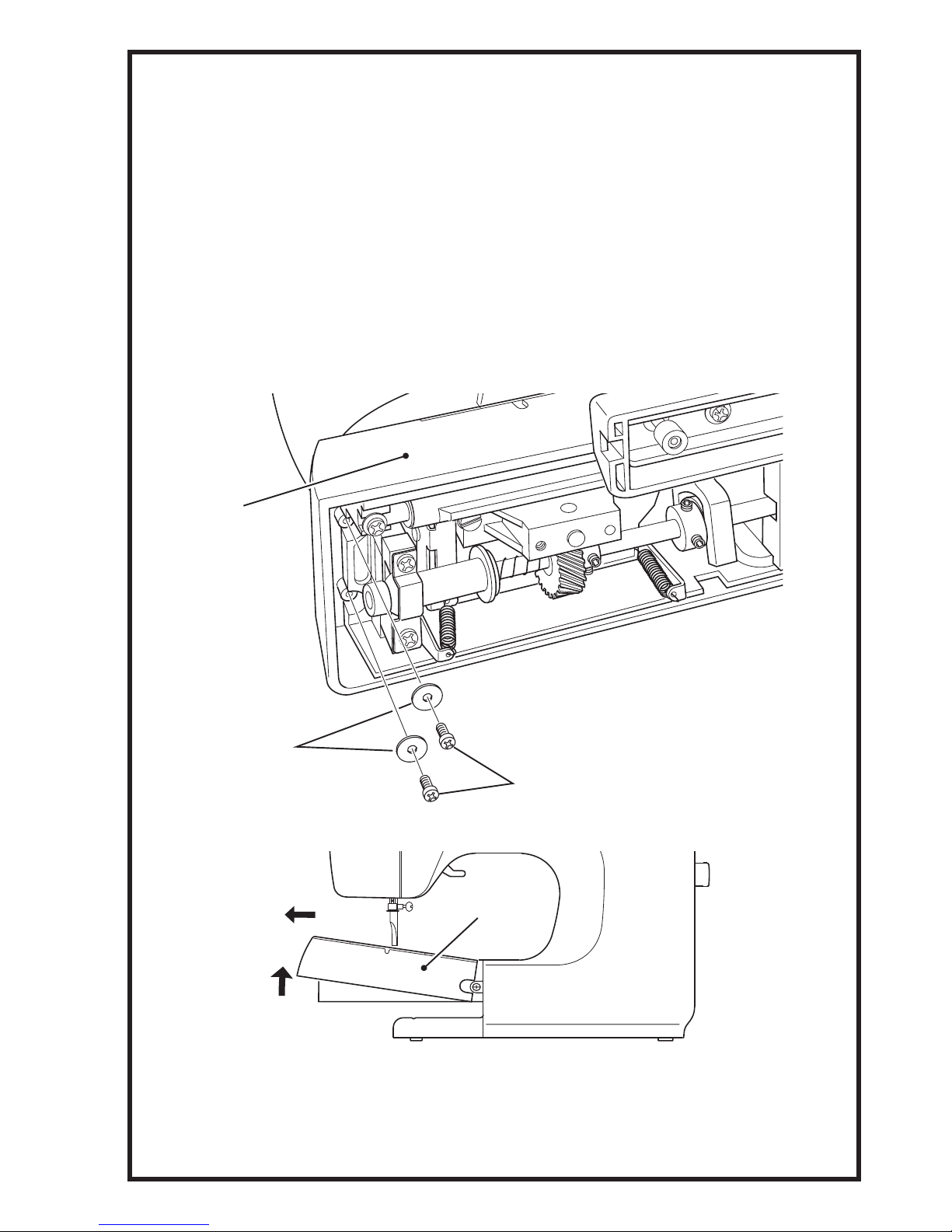

Bottom

cover

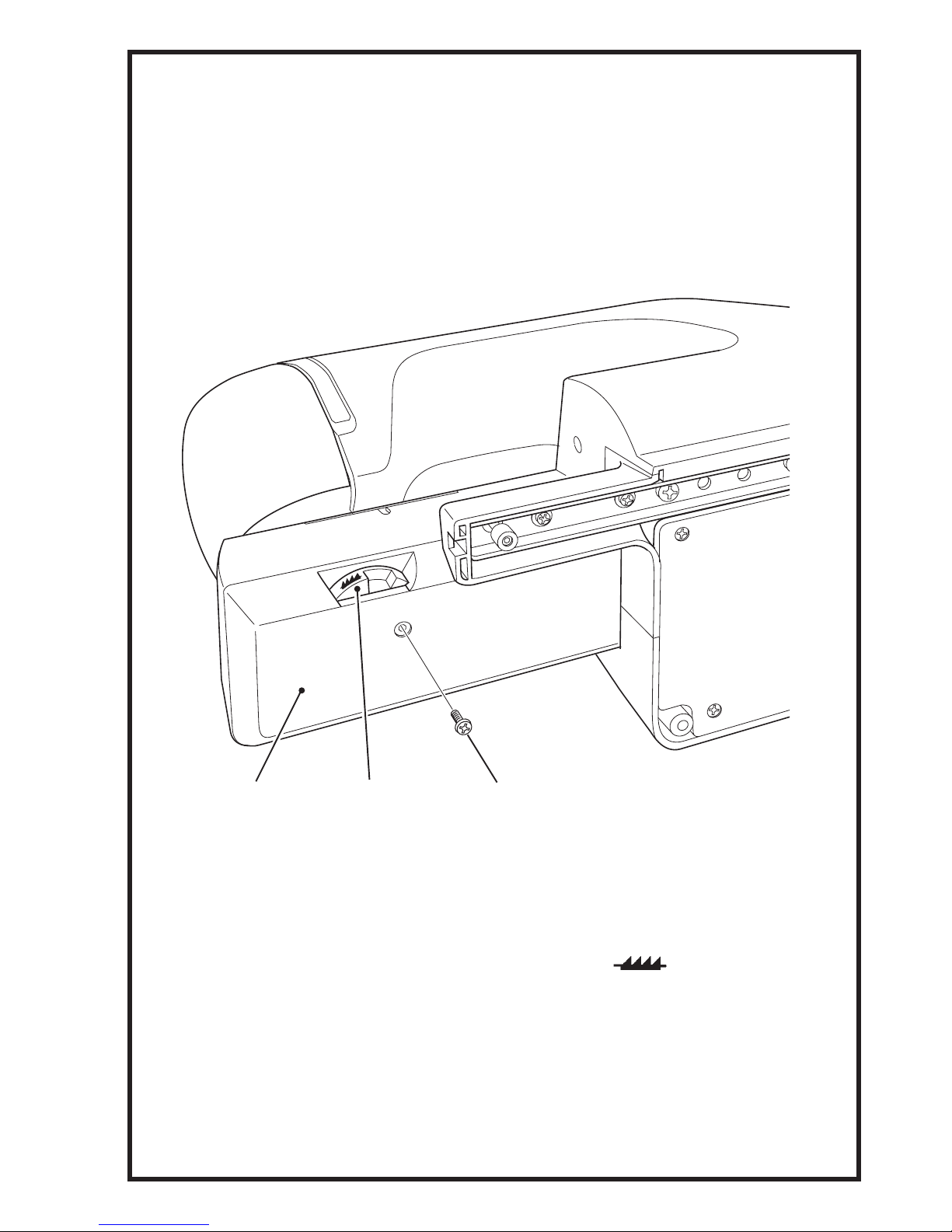

Base

cover

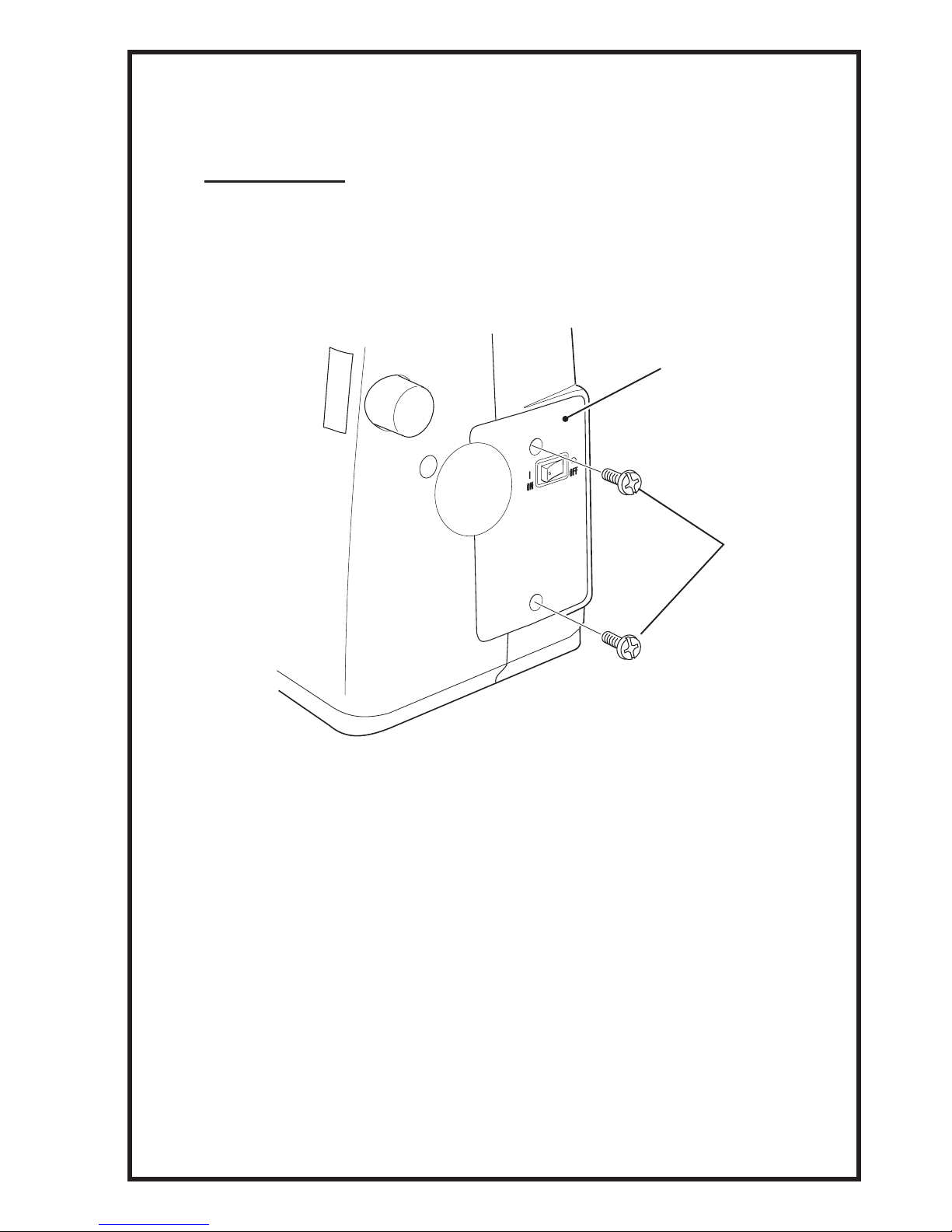

Te r m i n a l

cover

2 - 1 L-Positioner {

2 - 2 Needle Position at Straight

Stitchi ng {

2 - 3 Needle Position at Zigzag

Stitchi ng {

2 - 4 Maximum Zigzag Width {

2 - 5 Needle Side Motion {

2 - 6 Clearance between Zigzag

Cam and Cam Follower {

2 - 7 Feed Dog Height {

2 - 8 Space Between Feed dog

and Hole of Needle Plate {{

2 - 9 Feed Dog Timing Vertical

Movement {

2 - 9 Feed Dog Timing Lateral

Movement {

2 - 10

2 - 11

2 - 12 Buttonhole Sewing - '0'

Feeding (B) {

2 - 13 Balance of Stitch Length-

Stretch Stitching {

2 - 14 Presser Fot Height {

2 - 15 Needle Height {

2 - 16 Needle Clearance to Shuttle {{

2 - 17 Needle Timing to Shuttle {{

2 - 18 Adjustment of Stitch Selector {

2 - 19 Belt Tension {

2 - 20 Hooking Fork Position of

Needle Threader {

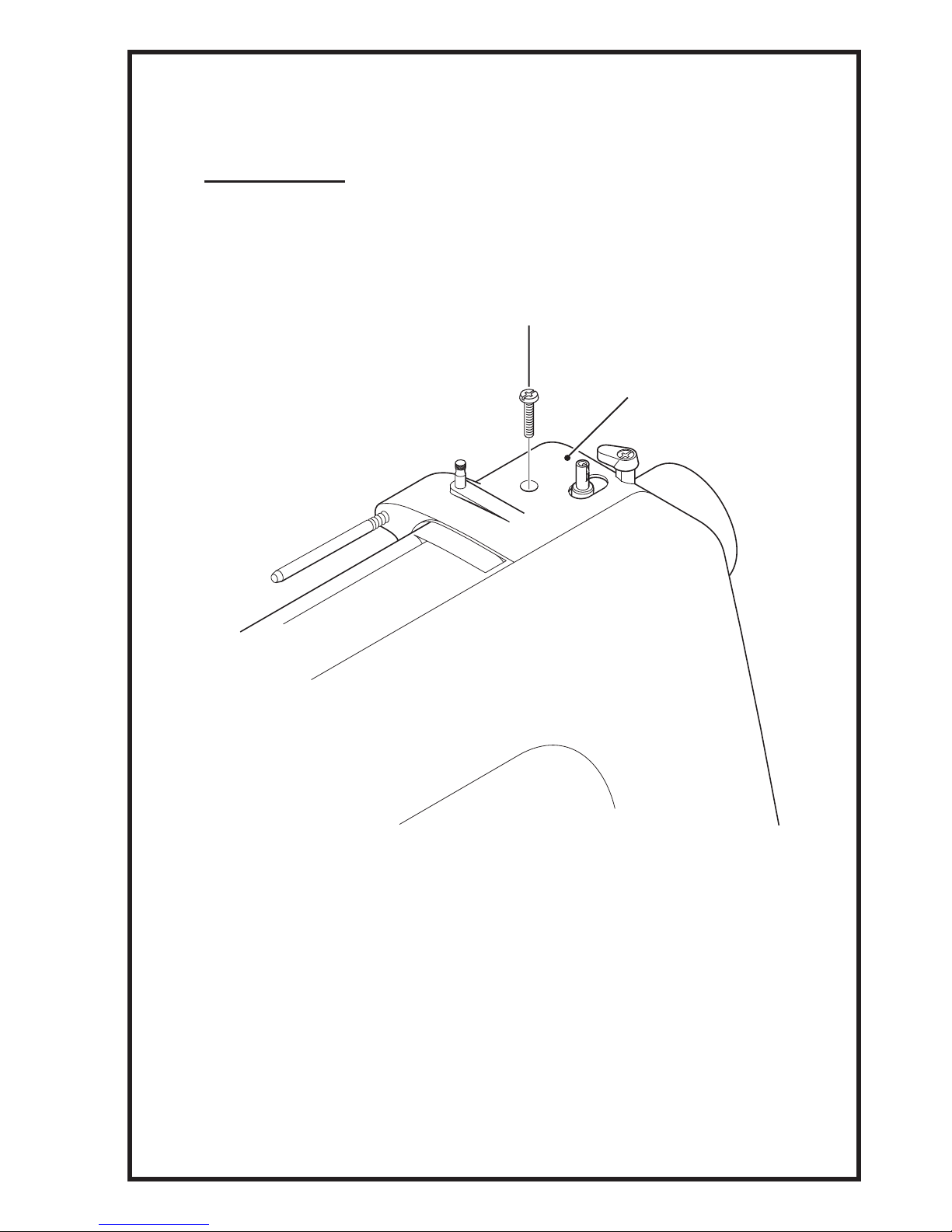

2 - 21 Bobbin Winder {

2 - 22 Buttonhole Changer {

2 - 23 Rubber Foot Height {

2 - 0

1

[ 2 ] ADJUSTMENTS

* Adjustment can be made with or without removal of outer parts.