CONTENTS

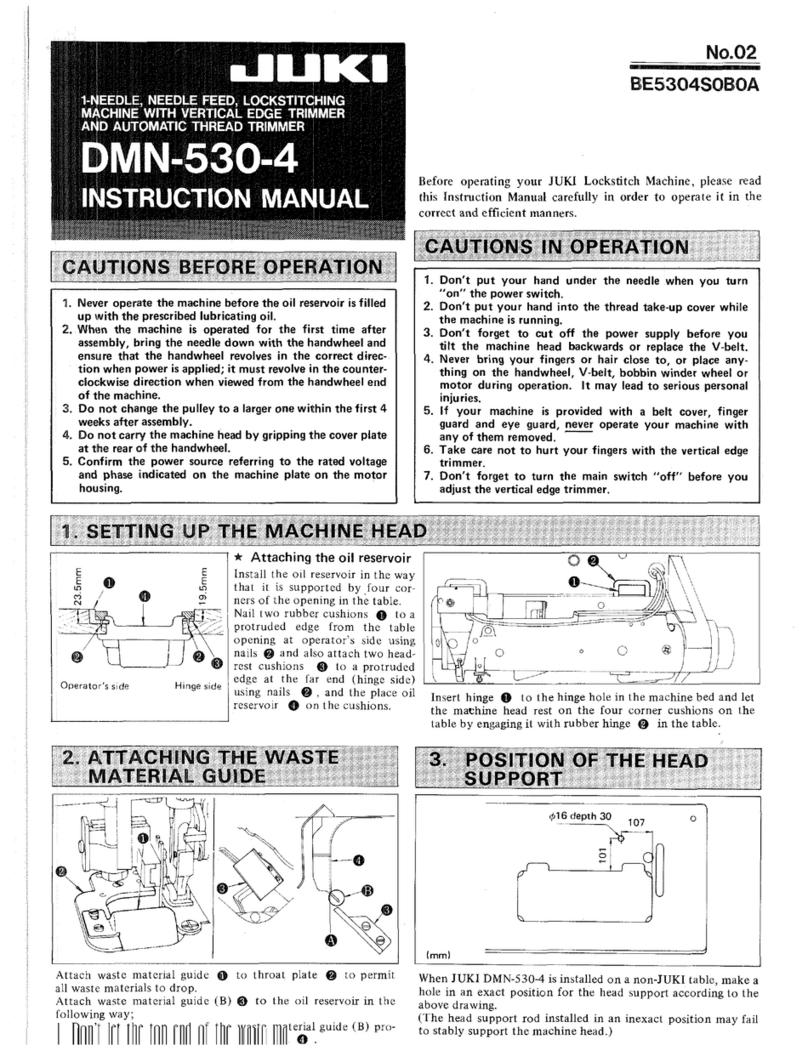

PREPARATION FOR OPERATION ……………………………………………… 1

1Installingtheaircylinderassembly ……………………………………………… 1

2Connectingtheelectriccablestothecontrolbox ……………………………… 1

3Adjustmentofthestitchlengthbeforetrimming ……………………………… 3

4Operationspeedadjustmentofinstantalternatingaircylinder ……………… 4

5Heightadjustmentoftheautomaticpresserfootlifter………………………… 4

6Adjustmentoftheneedlestoppingposition……………………………………… 5

USAGE PRECAUTION ……………………………………………… 6

1Lubrication( 1 ) ……………………………………………………………………… 6

2Lubrication( 2 ) ……………………………………………………………………… 6

3Lubricationcondition………………………………………………………………… 7

4Adjustmentoflubricationtotherotatinghook ………………………………… 7

5Precautionforthebuilt-intypedetector ………………………………………… 7

6Installationofthebeltcover ……………………………………………………… 7

7Precautiononoperation …………………………………………………………… 7

HOW TO USE ……………………………………………… 8

1Installationoftheneedle …………………………………………………………… 8

2Windingofthebobbinthread……………………………………………………… 8

3Selectionofthethread……………………………………………………………… 9

4Threadingoftheneedlethread…………………………………………………… 9

5Adjustmentoffeed(stitch)lengthandbackstitch……………………………… 10

6Settingofthebobbin………………………………………………………………… 10

7Adjustmentoftheneedlethreadguide ………………………………………… 10

8Threadingofthebobbinthread…………………………………………………… 11

9Adjustmentofthebobbinthreadtension………………………………………… 11

:Balanceofthreadstension ………………………………………………………… 11

AAdjustmentoftheneedlethreadtension………………………………………… 11

BAdjustmentofthepresserfootpressure………………………………………… 11

CAdjustmentoftheoutsidepresserfootandinsidepresserfoot ……………… 12

DInstantalternatingswitch ………………………………………………………… 13

EThestopperscrewforadjustingthemaximumalternatingstroke ………… 13

FInstallingthefeedregulatorbracket……………………………………………… 14

GAdjustmentofthealternatingstrokesensingpotentiometer ………………… 14

HTimingbetweentherotatinghookmotionandtheneedlemotion…………… 15

IAdjustmentofthefeeddogheight………………………………………………… 16

J

Relationshipbetweentherotatinghookmotionandthethreadtake-uplevermotion

… 17

KRelationshipbetweentherotatinghookmotionandtheopenermotion …… 17

LRelationshipbetweentheneedlemotionandthefeeddogmotion…………… 18

MSafetyclutch ………………………………………………………………………… 19

NAdjustmentofupperfeedlength(needleside) ………………………………… 20

OAdjustmentofforward/backwardfeedlength ………………………………… 20

PInstallationofthemovableknife…………………………………………………… 21

QInstallationpositionofthethreadtrimmercam………………………………… 22

RAdjustmentofthethreadtrimmercam ………………………………………… 22

SAdjustmentofthethreadtensionreleasing……………………………………… 23

T

Adjustmentofmeshingpressurebetweenthemovableknifeandthexedknife

… 24

USharpeningofthexedknife ……………………………………………………… 24

SPECIFICATIONS ……………………………………………… 25