Texi Post DD – Manual Instruction

CONTENTS

1.

1.1.

1.2.

1.3.

2.

3.

4.

5.

5.1.

5.2.

5.3.

5.4.

5.5.

5.6.

5.7.

6.

6.1.

6.1.1.

6.2.

6.3.

6.4.

6.5.

6.6.

6.7.

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

8.

8.1.

8.2.

8.3.

8.4.

8.5.

9.

9.1.

9.2.

9.3.

Safety……………………………………………………………………………………………………….

Safety symbol………………………………………………………………………………………………

Important points for the user……………………………………………………………………………..

Danger………………………………………………………………………………………………………

Proper use………………………………………………………………………………………………….

Specifications………………………………………………………………………………………………

Explanation of symbols……………………………………………………………………………………

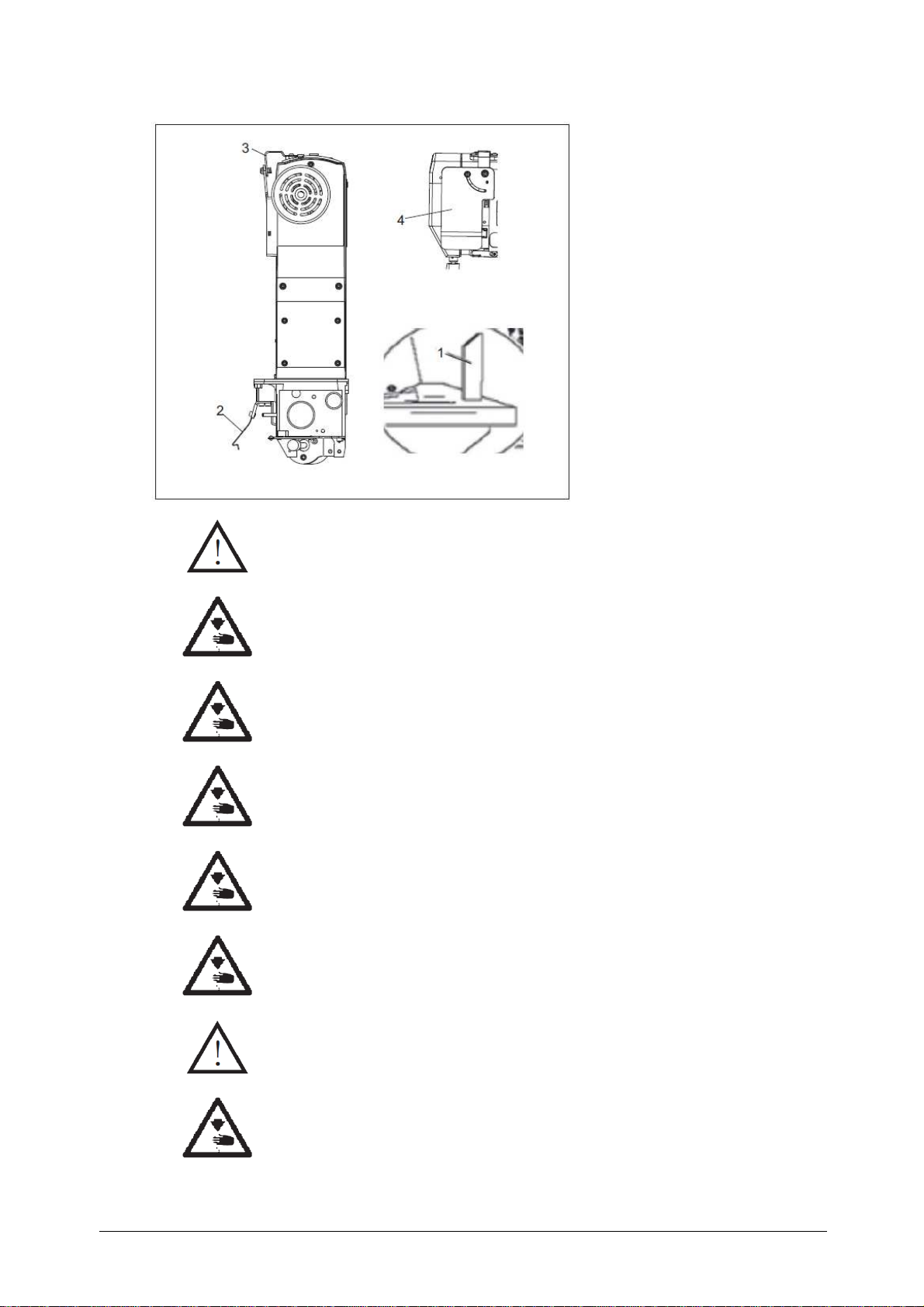

Controls…………………………………………………………………………………………………….

Keys on the machine head……………………………………………………………………………….

Bobbin thread monitoring with stitch counting………………………………………………………….

Pedal………………………………………………………………………………………………………..

Lever for lifting roller presser…………………………………………………………………………….

Knee lever………………………………………………………………………………………………….

Key for setting stitch length………………………………………………………………………………

Swing out roller presser…………………………………………………………………………………..

Installation and commissioning………………………………………………………………………….

Installation………………………………………………………………………………………………….

Adjusting the table height…………………………………………………………………………………

Fitting the reel stand……………………………………………………………………………………….

Install the Safety plate for tilting the machine head…………………………………………………….

Commissioning…………………………………………………………………………………………….

Tilted work base……………………………………………………………………………………………

Tilted work base……………………………………………………………………………………………

Mounting the table top…………………………………………………………………………………….

Preparation…………………………………………………………………………………………………

Inserting needle……………………………………………………………………………………………

Winding the bobbin thread; adjusting the primary thread tension…………………………………….

Removing/inserting the bobbin case…………………………………………………………………….

Threading the bobbin case/adjusting the bobbin thread tension……………………………………..

Threading the needle thread and regulating its tension……………………………………………….

Setting the stitch length……………………………………………………………………………………

Care and maintenance……………………………………………………………………………………

Cleaning……………………………………………………………………………………………………

Oiling the hook……………………………………………………………………………………………..

Oil bowl for hook lubrication……………………………………………………………………………..

Filling the oil reservoir of the thread lubrication unit…………………………………………………..

Lubricating the bevel gears………………………………………………………………………………

Adjustment…………………………………………………………………………………………………

Notes on adjustment………………………………………………………………………………………

Tools, gauges and other accessories……………………………………………………………………

Adjusting the basic machine……………………………………………………………………………...

1

1

1

2

3

3

4

5

5

5

6

6

7

7

8

9

9

9

9

10

10

11

11

12

13

13

14

15

15

16

16

17

17

17

18

18

19

20

20

20

20