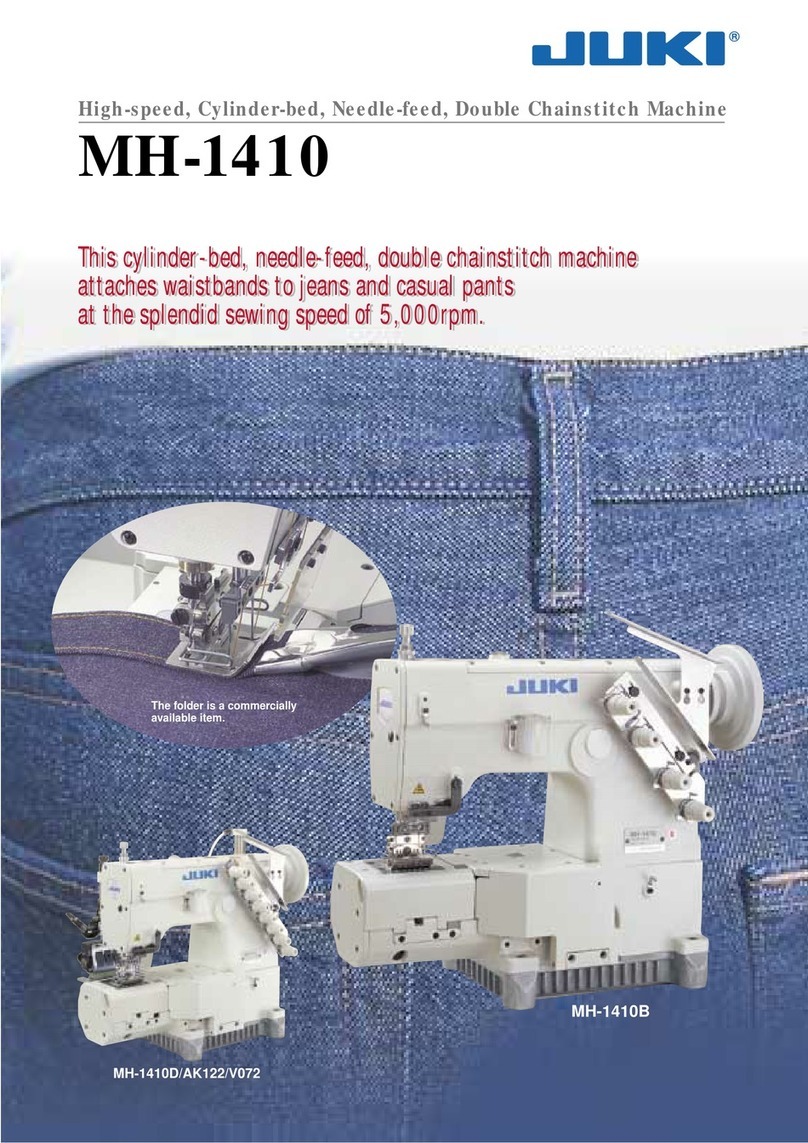

Height and inclination of the

feed dog can be adjusted Thefeedmethodcanbechanged

over between the needle-feed

and the bottom-feed Upgraded maintainability

Both the height and inclination of the

feed dog are easily adjustable. Adjust

the feed dog according to sewing

conditions such as the specification,

process, and material to be sewn.

Through a simple adjustment of the

machine and replacement of the gauge, the

feed method can be changed over between

the needle-feed and bottom-feed types.

When the bottom-feed method is selected,

the needle entry position can be adjusted

(in the feeding direction) using the needle-

feed/bottom-feed change-over mechanism.

This allows the machine to flexibly adapt to

commercially available gauges.

●When replacing the gauge, the screw

in the hook-driving shaft saddle can be

tightened diagonally from above to

ensure safety and operability.

●The hook is lubricated automatically

when adjusting the oil discharge. This

helps stabilize and regulate amount of

oil in the hook more effectively.

■WHENYOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

●To order, please contact your nearest JUKI distributor.

Needle

gauge

mm

3.2

4.8

6.4

7.1

7.9

Feed

Needle-feed

Bottom-feed✽

inch

1/8

3/16

1/4

9/32

5/16

B

D

F

G

H

Code Code

Code

1P

4✽

Attachment

Combination availability table

C

Automatic reverse

feed function

Automatic reverse

feed function SC-910

SC-800

Standard throat plate, standard slide plate,

standard presser foot

Pedal switch type

(AK89)✽

Not provided

Provided

Code

A

B00

0B

Hook

Latch hook

Hook with

non-rotational

bobbin

Throat plate for tape-attachment, slide plate for tape-

attachment, presser foot for tape-attachment

Code

0

Motor✽

Compatible with clutch motor

(without synchronizer and

resistor pack)

1

Compatible with SC-800 and EC-10B

(with built-in synchronizer and

resistor pack)

Code

S

Auto-lifter

Not provided

Motor

0

(Not provided)

B

(Provided)

Cluth motor EC-10B

Where "0" is selected

Where "1" is selected

Where "0" is selected

Where "1" is selected

○

×

×

×

×

○

×

○

×

○

×

○

Code

Z

✽For the "Bottom-

feed: B," only the

needle gauges B,

D, and F are

applicable.

✽For the above category 4, select the feed category A (needle-feed). ✽For the AK-89, select the

motor compatibility category 1

(SC-910, SC-800 or EC-10B).

✽Refer to the combination availability table.

✽Refer to the combination

availability table.

LH3126F

Adjustment of the

feed dog inclination

Adjustment of the

feed dog height

Hook oil

regulating screw

Needle-feed

Bottom-feed

■SPECIFICATIONS ■OPTIONS

■WHENYOU PLACE ORDERS

■SPECIFICATIONS ■OPTIONS

●Micro-lifter

Part No.: 236-11056

This device can be installed on

the back of the face plate. It is

very convenient for frequent

use.

●

Automatic reverse feed kit

Part No.: 226-56854

The automatic reverse feed

function device can be moun-

ted on the machine after the

setup. This device can be in-

stalled on the back of the face

plate. It is very convenient for

frequent use.

●Tension-free feeder

(tape feeder)V059

Part No.: MAV-059000AA

The amount of tape to be fed

can be adjusted in accordance

with the sewing speed of the

machine. It is adaptable to

processes for attaching rein-

forcement tape, attaching elas-

tic tape or lace to foundation.

●Tape cutter AT-36

The tape cutter is able to cut

the tape just behind the press-

er foot (20mm away from the

needle entry point).

The cutter pressure is adjust-

able according to the material

thickness.

Max. sewing speed

Max. stitch length

Thread take-up

Needle bar stroke

Lift of the presser foot

Hook (selectable)

Needle

(at the time of delivery)

Feed system

Lubrication

Distance from

needle to machine arm

Bed size

Weight of the machine

head

3,000rpm

4mm (normal / reverse feed)

Slide type

33.4mm

By hand : 5.5mm / By knee : 12mm

Vertical-axis hook (regular fold)

Specific latch hook or specific hook with non-rotational bobbin

DP

×

5 (#10) #9

〜

#11

Change-over between needle-feed / bottom-feed

Fully automatic lubrication system by means of plunger pump

245mm

517mm

×

178mm

43kg

Adjustment of the

feed dog inclination

Adjustment of the

feed dog height

Hook oil

regulating screw

Needle-feed

Bottom-feed

■WHENYOU PLACE ORDERS

■SPECIFICATIONS ■OPTIONS