To order, please contact your nearest JUKI distributer.

■

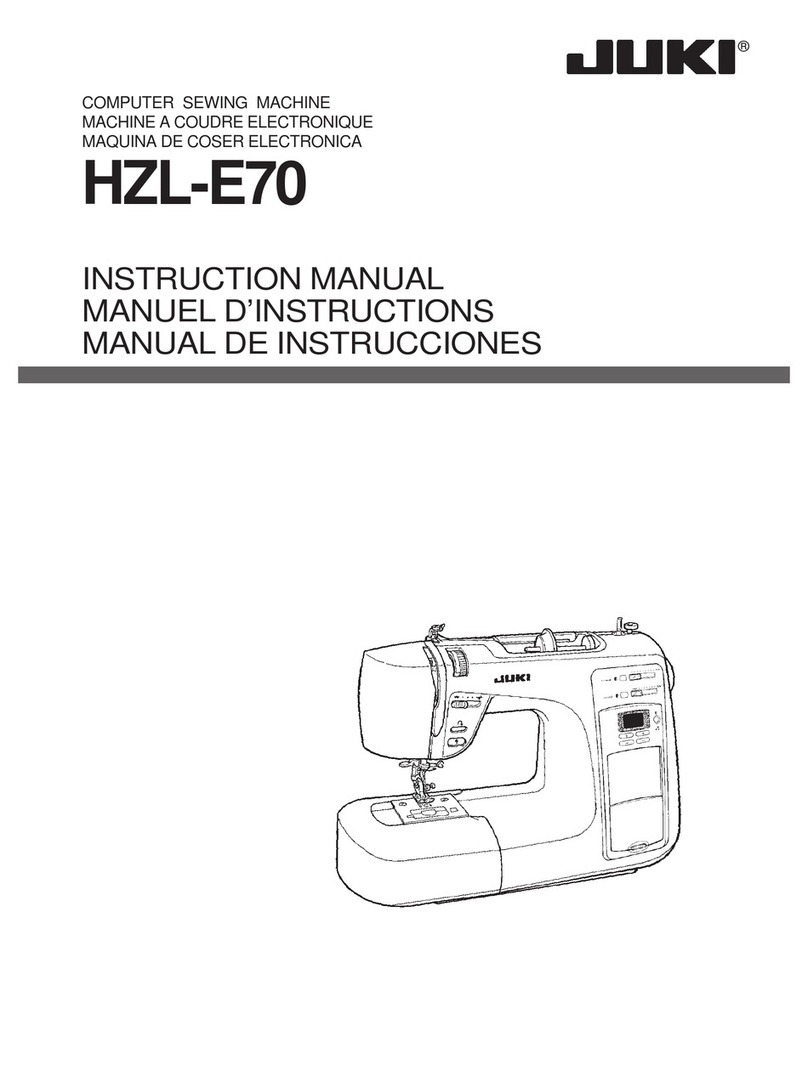

This machine can be used for extra light-

weight materials including lawn and organdy,

medium-weight materials including those used

for blouses and handkerchieves, and heavy-

weight materials on which names and labels

are to be embroidered. Beautifully finished

seams free from needle swaying or material

breakage are assured every time.

!

The zigzag width is regulated up to 12 mm

using the knee lifter. This knee lifter has been

designed to fit the jut-type knee lifter widely

used by zigzag stitch machines.

" #$ %&

Highly durable and reliable components are

used as its major parts, including the needle

bar oscillating mechanism, thereby leading to

smooth running without vibration even at

high speed, the result of which is consistent,

high-quality seams.

■

' ()*

A compass and cord embroidering attachment can be installed on the machine.

The compass (asm.) (B3352-271-0A0) and scallop (asm.) (B5001-271-0A0) can be ordered from s as options.

■

+#''#'),

LZ-271

',-'. /',0 1#2', -'3

✽

Specifications and appearance are s bject to change witho t prior notice for improvement.

✽

Read the instr ction man al before p tting the machine into service to ens re safety.

✽

This catalog e prints with environment-friendly soy ink on recycle paper.

JUNE, 2010 Printed in Japan(A)

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO 206-8551, JAPAN

PHONE :

(81)42-357-2254

FAX :

(81)42-357-2274

http://www.j ki.com

J ki Corporation operates an environmental management system

to promote and cond ct the following as the company engages in

the research, development, design, sales, distrib tion, and

maintenance of ind strial sewing machines, ho sehold sewing

machines, ind strial robots, etc., and in the provision of sales and

maintenance services for data entry systems:

➀

The development of prod cts and engineering processes that

are safe to the environment

➁

Green proc rement and green p rchasing

➂

Energy conservation (red ction in carbon-dioxide emissions)

➃

Reso rce saving (red ction of papers p rchased, etc.)

➄

Red ction and recycling of waste

➅

Improvement of logistics efficiency (modal shift and improvement

of packaging, packing, etc.)

Using the j t-type knee lifter with the

zigzag width pointer released

Applications

Needlebar stroke

Needle

Zigzag width

Zigzag width reg lating method

Hook

L brication method

Material handling area on the machine

Sewing speed

Embroidering on light-, medi m- and heavy-weight materials

33.4 mm

DB x 1 #9 thro gh #18 (standard : #11)

0~12mm

Using the j t-type knee lifter with the zigzag width pointer released.

DB-type hook for embroidering

Centralized l brication ( sing an oiler)

270 mm (from the needle entry to the bottom of the arm)

Max. 2,000 sti/min

*

(with a zigzag width is as large as 10 mm)

Normal 1,700 sti/min

*

(with a zigzag width is as large as 12 mm)

*sti/minstands forStitches per Minute.