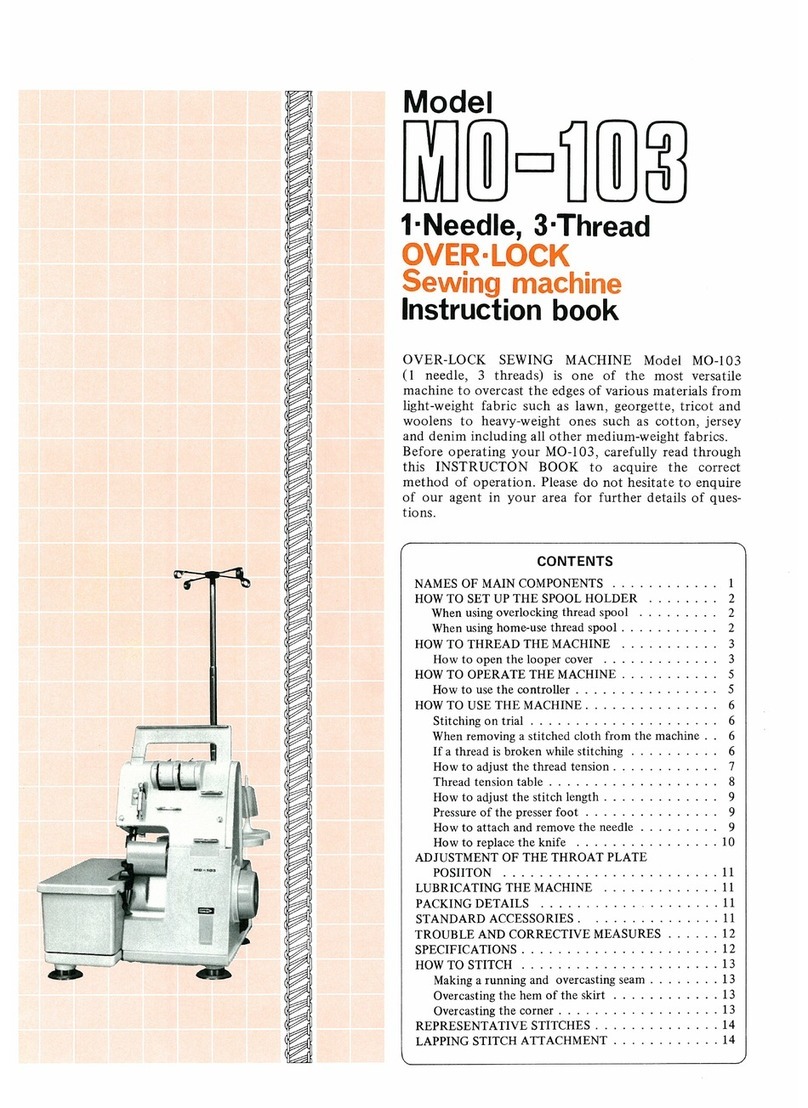

Needle thread tension controlled by active-tension.

(electronic thread-tension-control system)

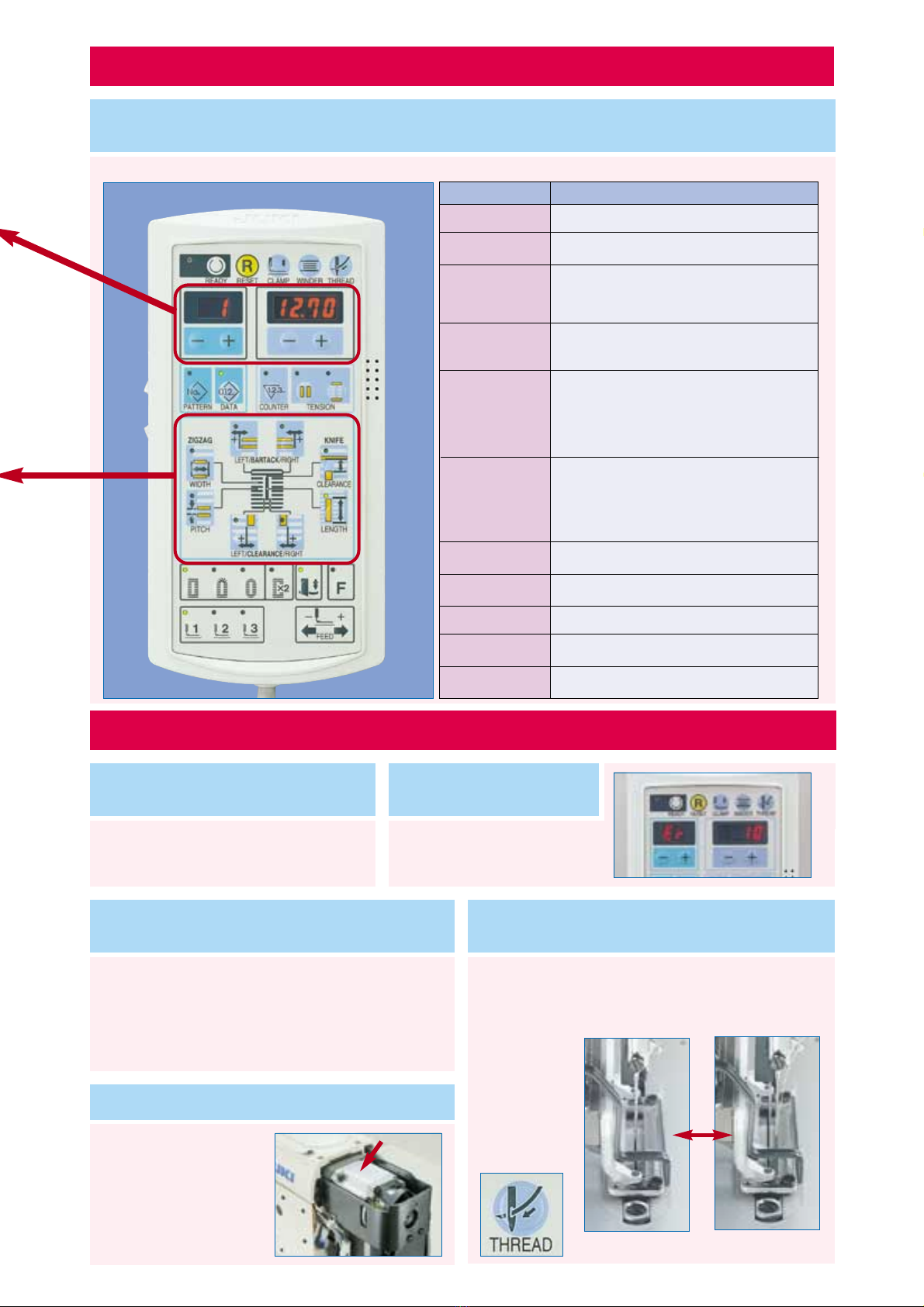

IMPROVEMENTS OF SEWING PERFORMANCE

• Needle thread tension for sewing parallel and bartacking sections of buttonholes

can be separately controlled through the operation panel and stored in memory

according to various sewing conditions (e.g., type of thread, type of material and

sewing speed).

• The machine is able to change the needle thread tensions at the parallel and

bartacking sections of the buttonhole, to produce a

beautiful buttonhole shape.

This capability helps greatly in preventingthread breakage.

• Needle thread tension is activated at the beginning and

end of sewing. This prevents unthreading of the needle

thread, and thread fraying that is likely to occur at the

beginning of sewing.

Reduction in

cycle time.

HIGHER PRODUCTIVITY

•The duration of low

speed sewing, before

the end of sewing, has

been shortend.

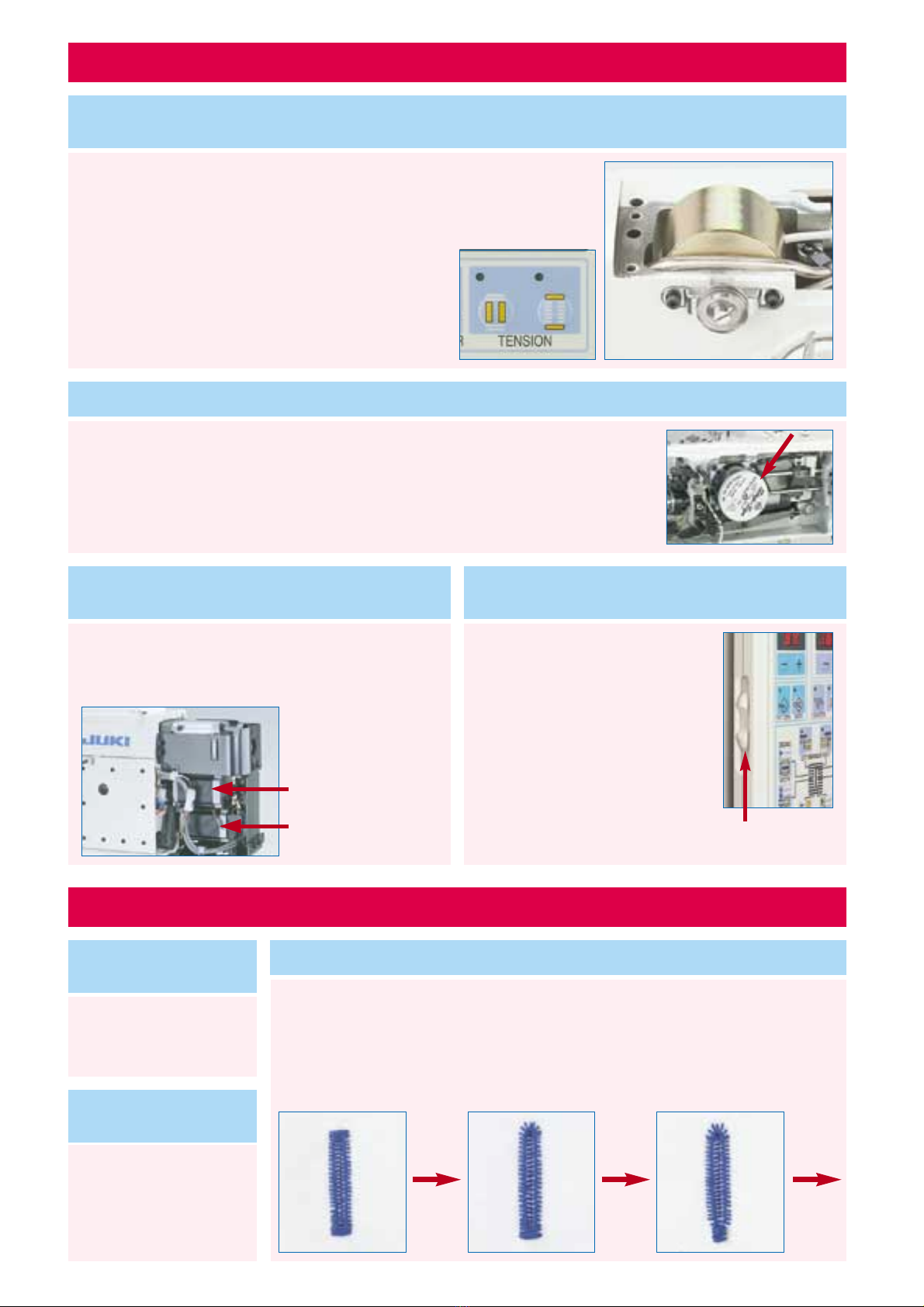

The machine is able to perform cycle sewing.

• Three different cycle sewing programs can be registered, each of which can store

up to 15 different patterns in memory.

• Data on needle thread tension, buttonholing length, stitching shape, etc., can be entered

to enable automatic changing according to a specific sewing condition.

<Example> Men's shirts : Change in the needle thread tension for sewing the first

button from the cuffs and change in button size for a button-down collar.

Ladies' wear : Change in buttonhole shape

Totalproductivity

is increased.

•The amount of time

required to change the

stitching shape and to

adjust the sewing size is

dramatically reduced at

the digital operation

panel.

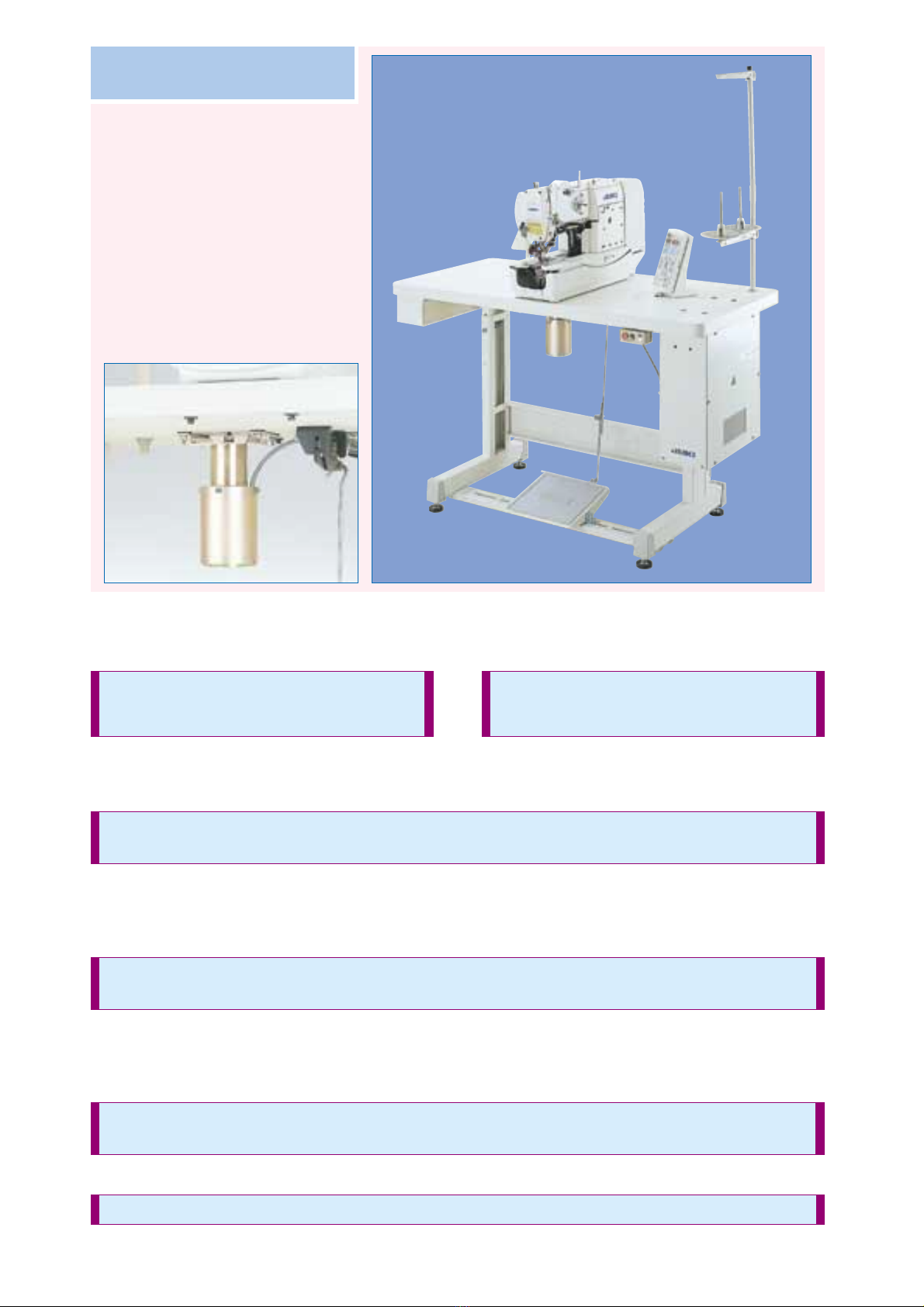

Active tension

Feed mechanism using a stepping motor.

• The feed mechanism eliminates differences in stitch pitch between forward and

reverse feeds. This produces beautifully-shaped buttonhole.

• The feed mechanism achieves constant position stopping at the end of sewing.

• The feed mechanism allows the machine to sew exact square bartacks and exact

round tacks.

• The machine comes with an intermittent feed system to eliminate stitch skipping

or thread breakage due to needle swaying.

• The cloth cutting length (buttonhole length) can be easily changed at the operation panel.

Base line is controlled by a

stepping motor.

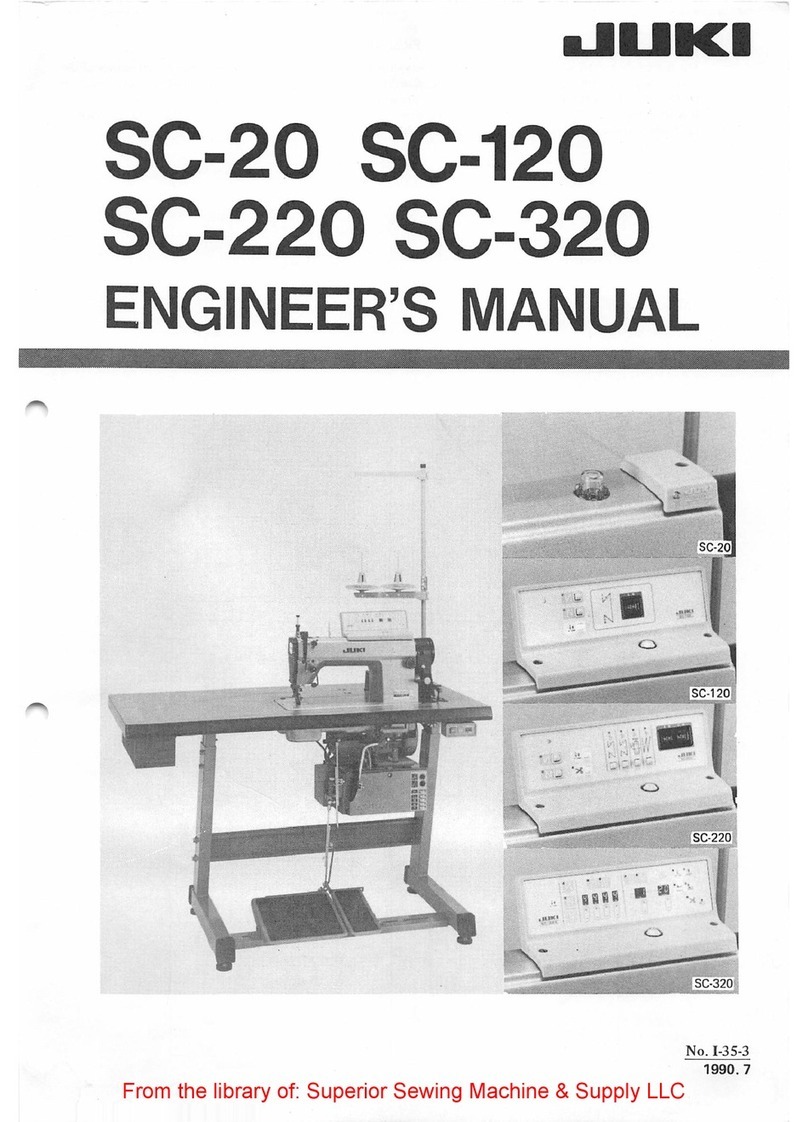

• The zigzag width can be changed without having to use a

tool.

• The optimum clearance between the knife and the parallel

section of a buttonhole can be easily adjusted to prevent

the knife from cutting

the seam.

Stepping motor for

controlling base line.

Stepping motor for

controlling zigzag width.

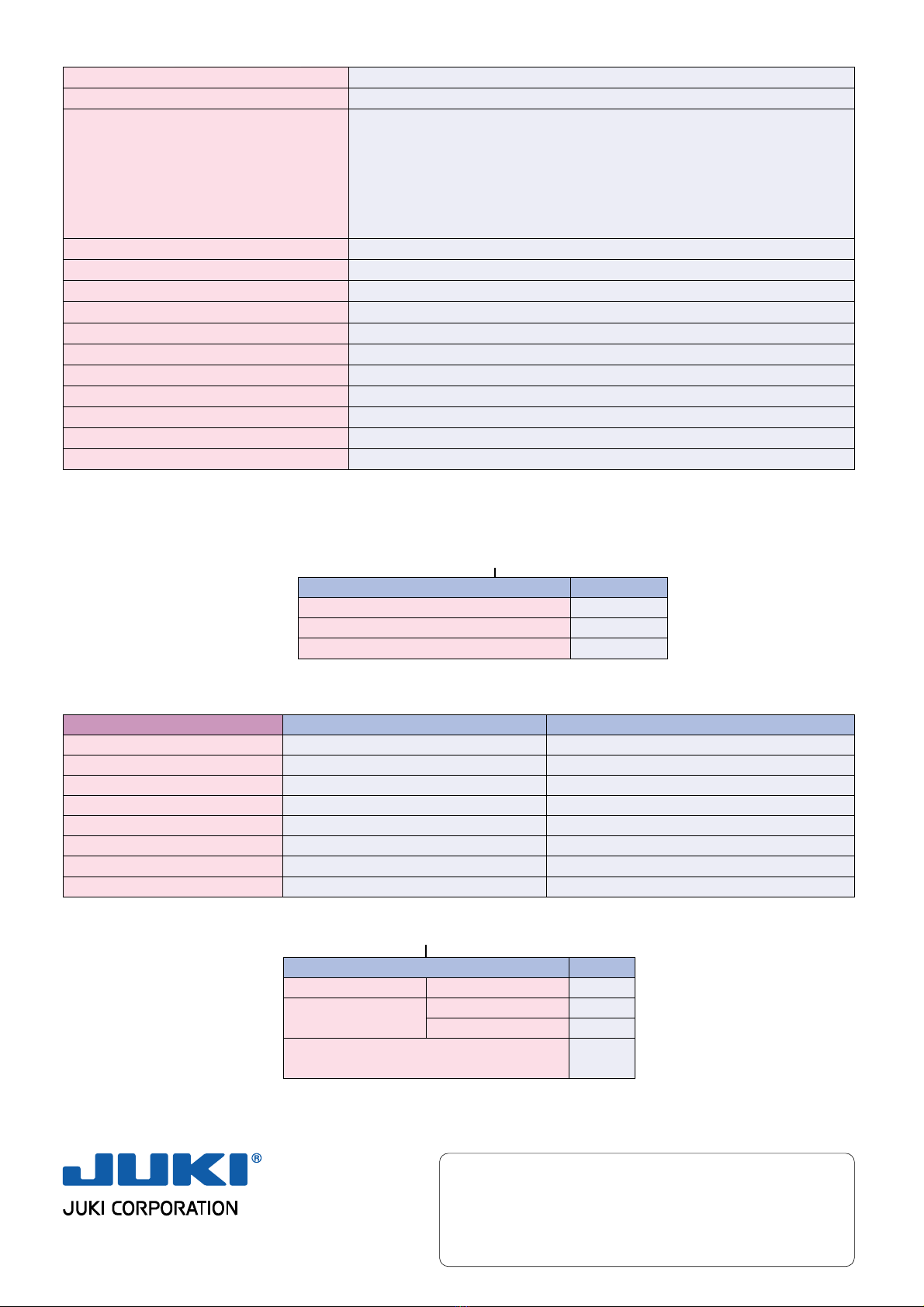

Tying stitches, soft start and speed

control.

•The machine is capable of sewing

tying stitches at the end of sewing to

prevent the thread from fraying.

•With its soft-start function, the

machine is able to establish the

number of stitches and sewing speed

at the beginning of sewing to prevent

unthreading of the needle thread.

The sewing speed can be

independently controlled for the

first through fifth stitch.

• With the speed control function, the

sewing speed can easily be changed

to a lower speed when sewing

difficult-to-sew material.

Slide speed

controller