i

CONTENTS

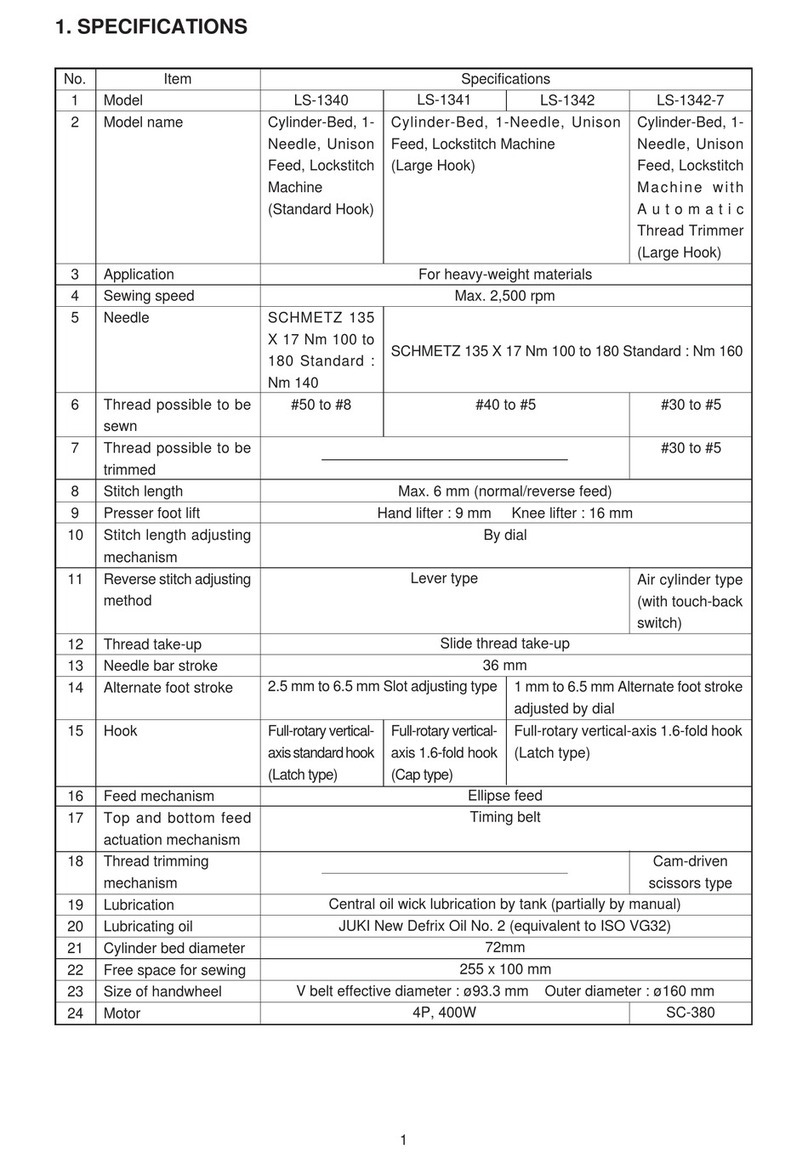

I. SPECIFICATIONS.............................................................................................................1

II. AT THE BEGINNING........................................................................................................1

III. INSTALLING THE ACCESSORIES................................................................................2

1. Installing the presser lifting cylinder ..................................................................................... 2

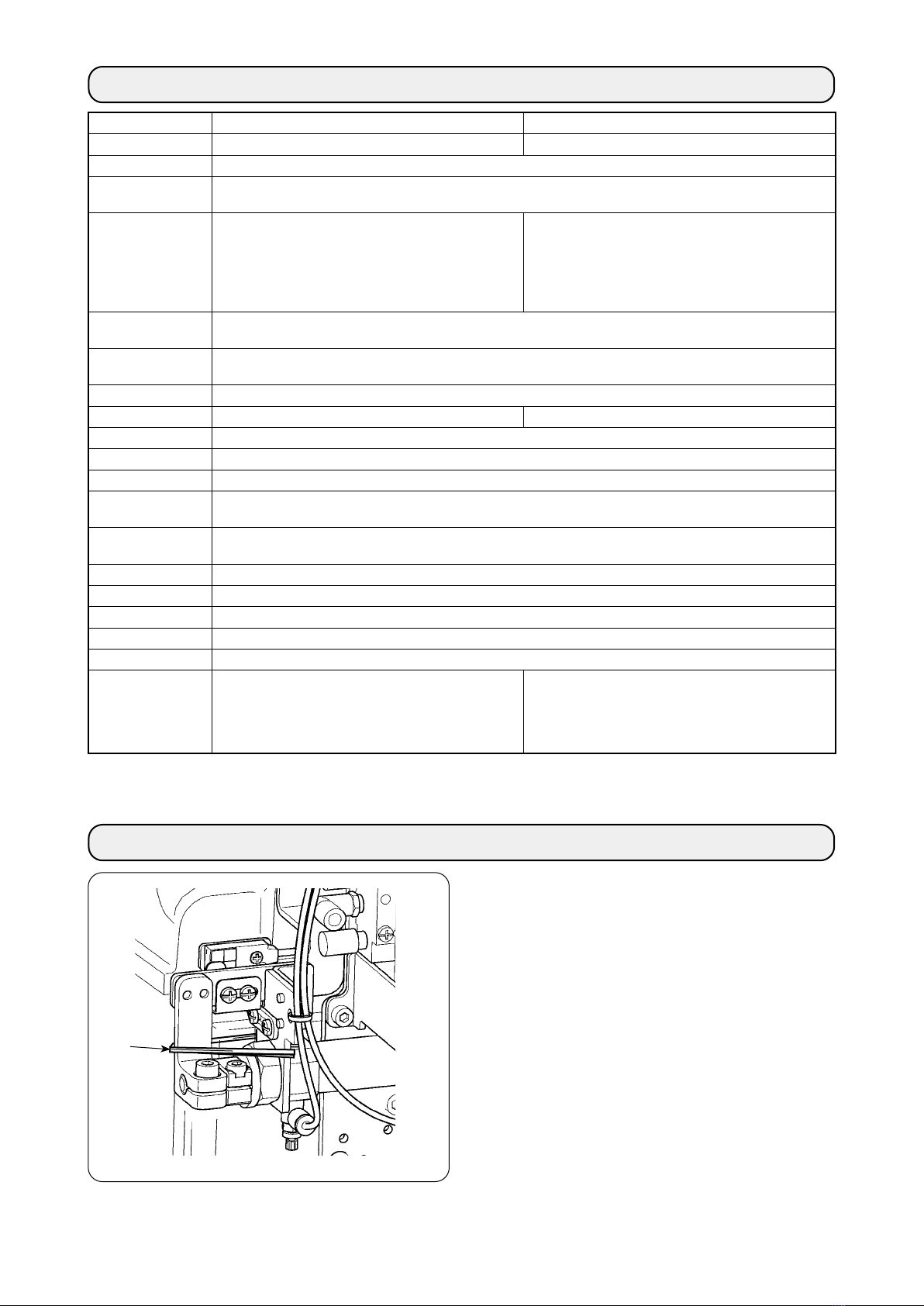

2. Installing the air regulator....................................................................................................... 2

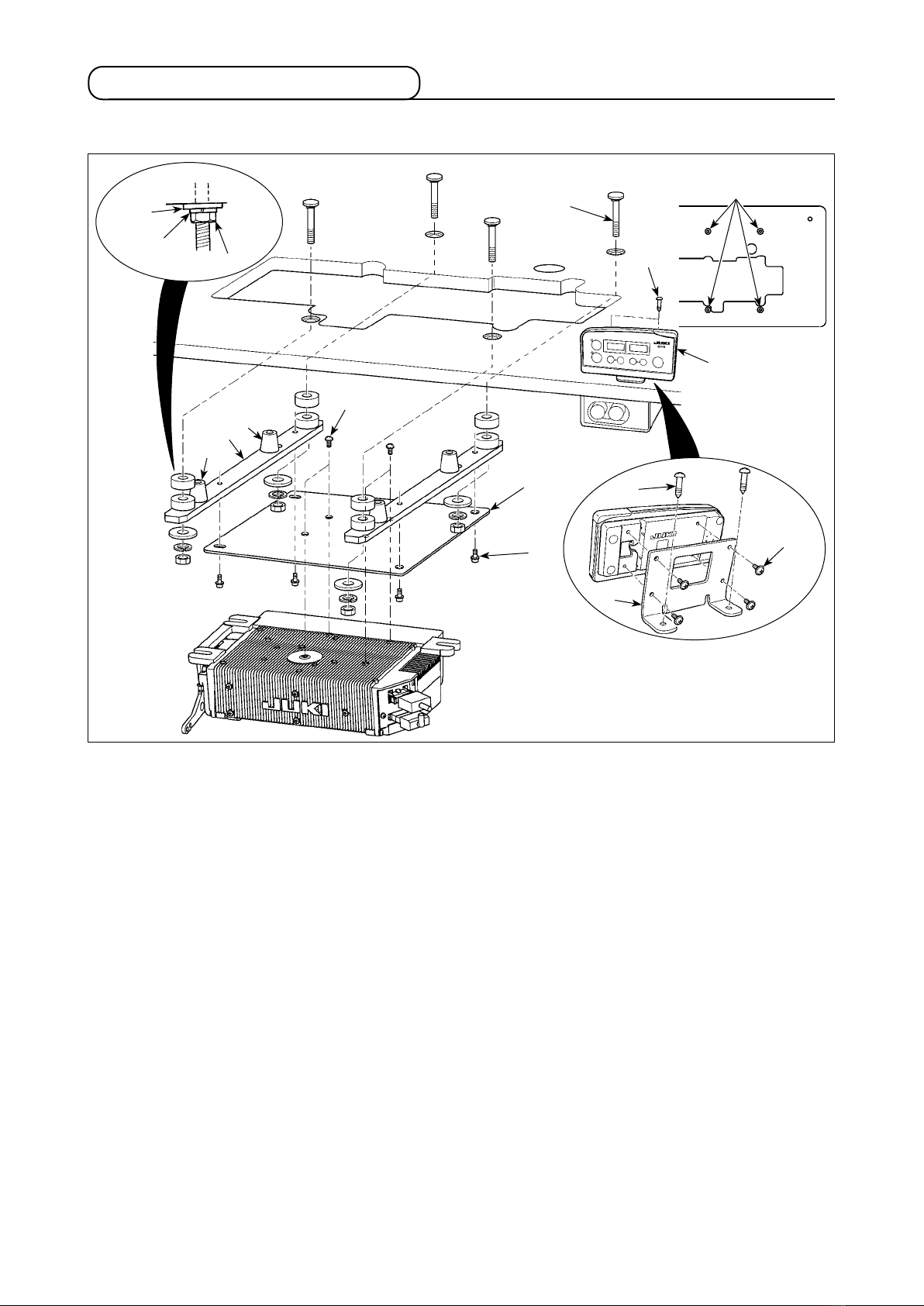

3. Installation and setting SC-921............................................................................................... 3

(1) Installing the SC-921 on the table ( Semi-submerged type ).............................................. 3

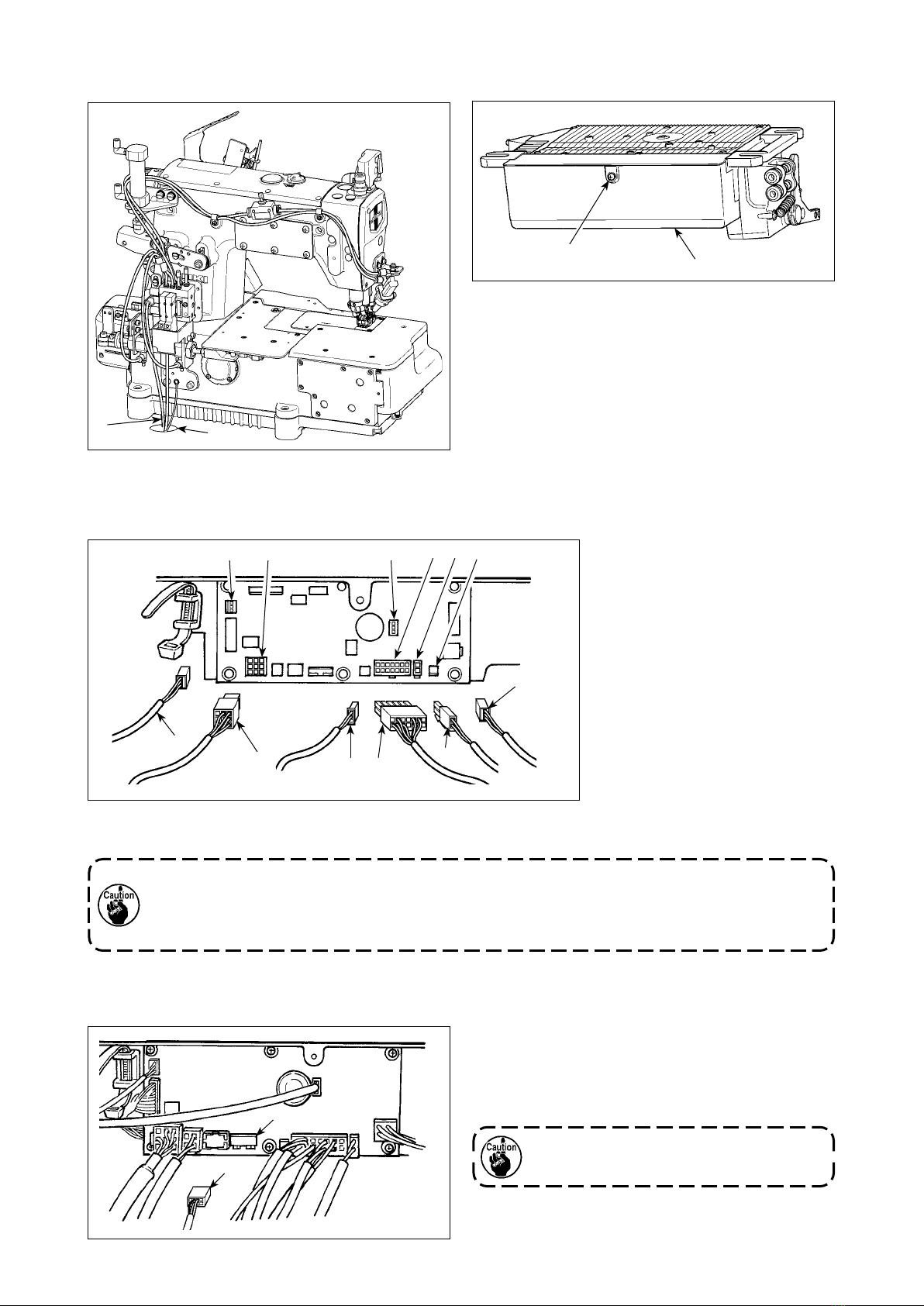

(2) Connecting the cords ............................................................................................................ 4

(3) Setting procedure of the machine head............................................................................... 5

(4) Setting the lower stop position of the needle bar ............................................................... 6

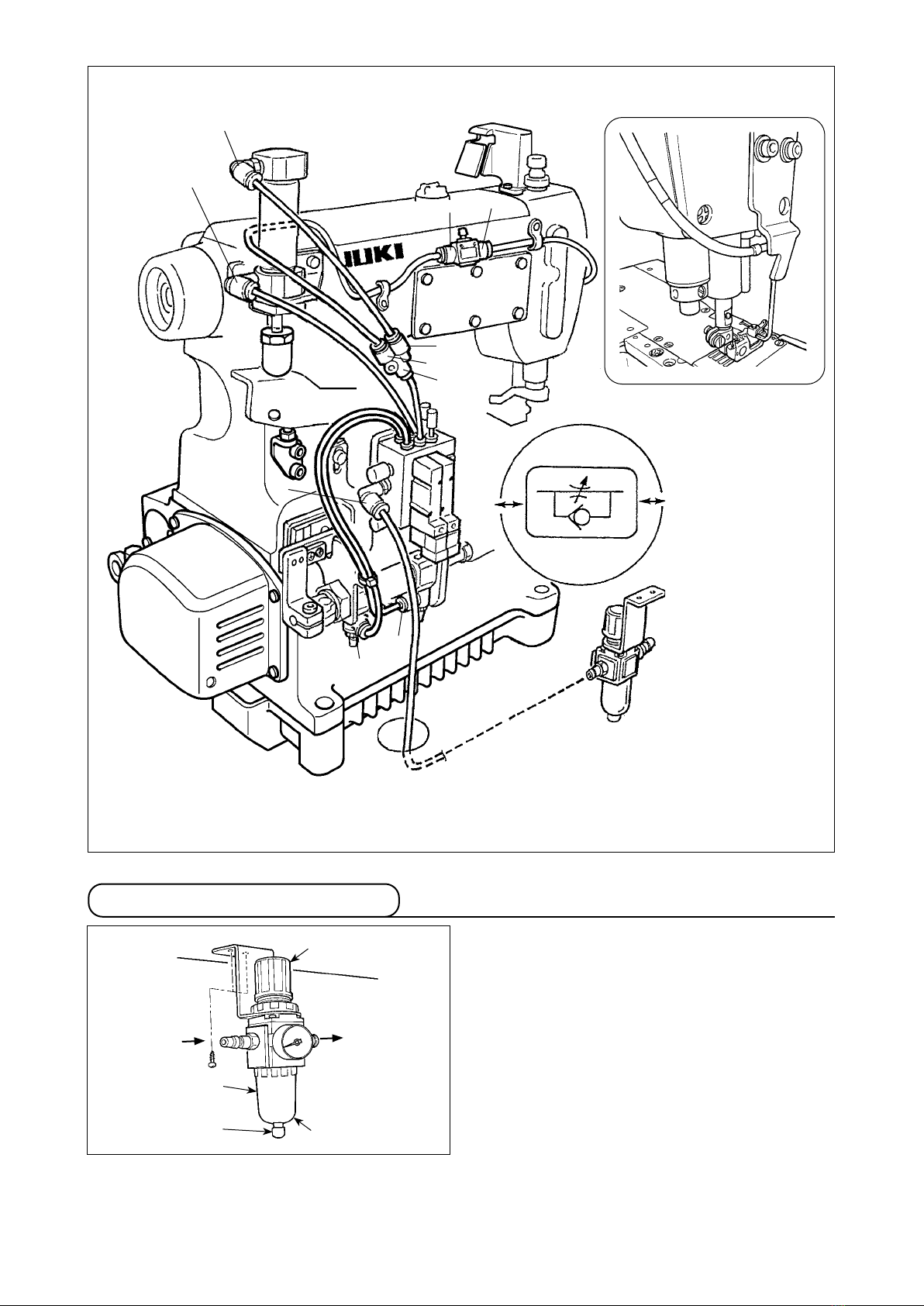

IV. AIR PIPING DRAWING...................................................................................................7

1. Piping of the thread trimmer device....................................................................................... 7

2. Adjusting the air regulator ...................................................................................................... 8

V. THREADING THE MACHINE HEAD...............................................................................9

VI. ADJUSTING THE LOOPER THREAD TRIMMER MECHANISM ................................10

1. Adjusting the thread trimmer air cylinder ........................................................................... 10

2. Adjusting the Lower knife ..................................................................................................... 11

3. Adjusting the position of clamp pressure adjusting spring .............................................. 11

4. Adjusting the knife engagement and the knife pressure adjusting spring ...................... 11

5. Adjusting the pressure of clamp spring .............................................................................. 11

6. Initial position of the looper thread trimmer mechanism................................................... 12

7. Adjusting the stopper............................................................................................................ 12

8. Adjusting the height of the lower knife................................................................................ 12

9. Adjusting the longitudinal position of the blade point of lower knife .............................. 13

10. Adjusting the thread trimmer sensor................................................................................... 13

11. Adjusting the speed of looper thread trimmer.................................................................... 13

VII. ADJUSTING THE THREAD RELEASE MECHANISM ...............................................14

1. Adjusting the disk-rise .......................................................................................................... 14

2. Adjusting the thread release hook ....................................................................................... 14

VIII.

ADJUSTING THE TOP COVERING THREAD TRIMMER MECHANISM ............................. 15

1. Adjusting the engagement of knives ................................................................................... 15

2. Adjusting the pressure of clamp spring .............................................................................. 15

3. Adjusting the position of the blade point of moving knife ................................................ 15

4. Adjusting the speed of moving knife ................................................................................... 16

IX. ADJUSTING THE AIR-BLOW WIPER (ACCESSORIES)............................................17

1. Installing the air-blow wiper.................................................................................................. 17

2. Adjusting the air-blow wiper................................................................................................. 17

X. MAINTENANCE.............................................................................................................18

1. Cleaning the motor fan.......................................................................................................... 18