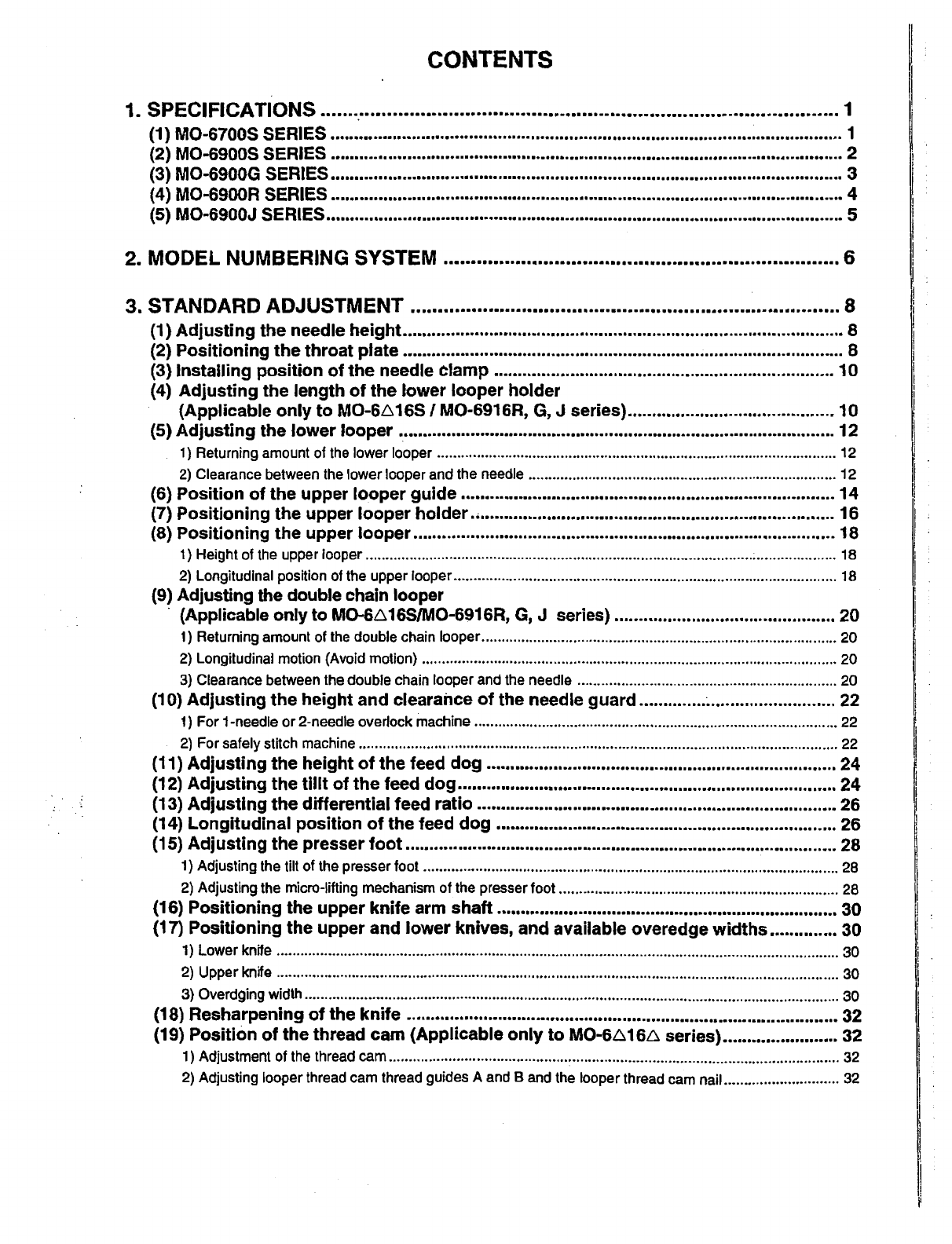

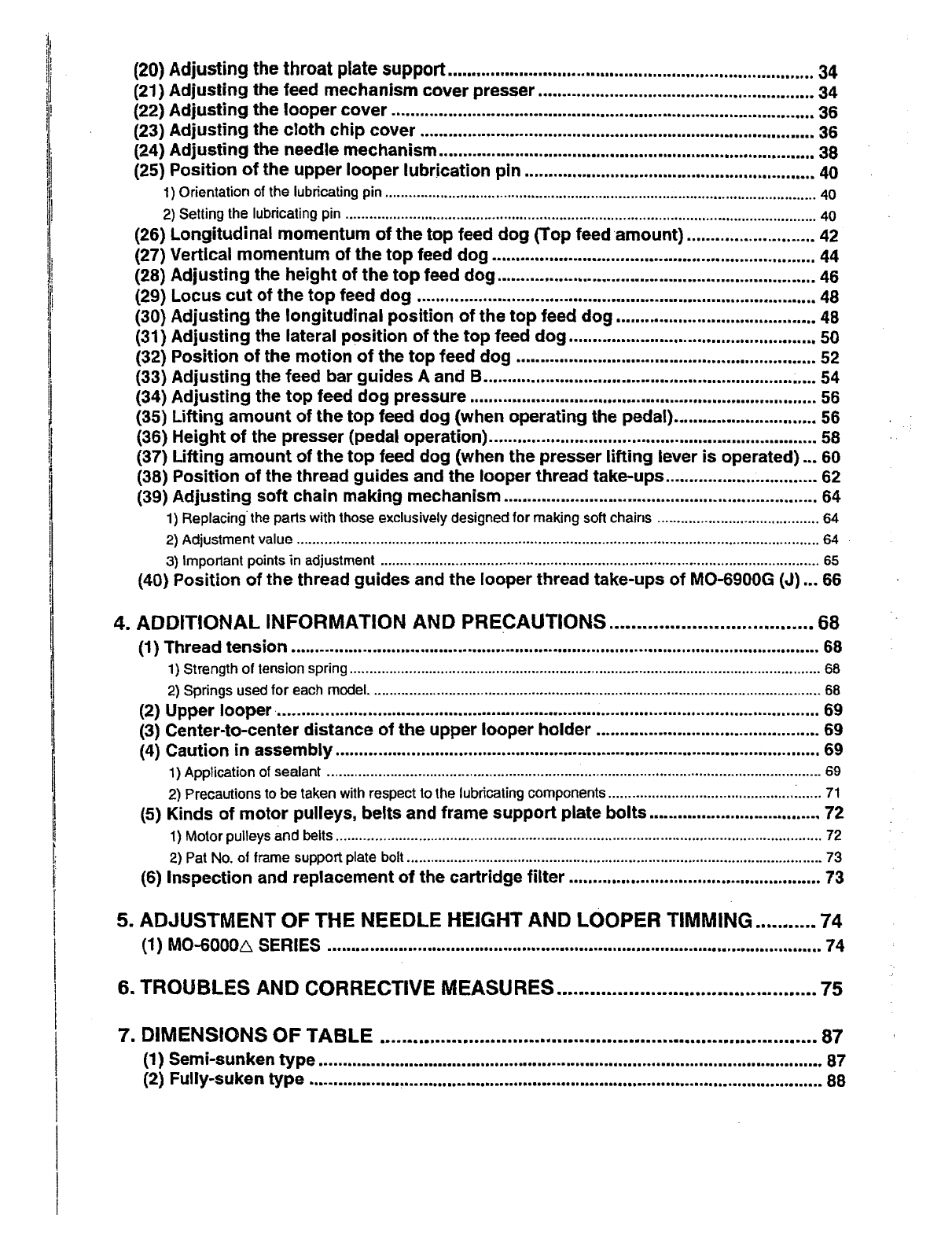

CONTENTS

1. SPECIFICATIONS ......._...•....•..•••.•.••••...•••..••••.••.••••••..•.••...••..•........•..•••.•..•••.••.•... 1

(1) MO-6700S SERIES ........................................................................................................... 1

(2) MO-6900S SERIES ...........................................................................................................2

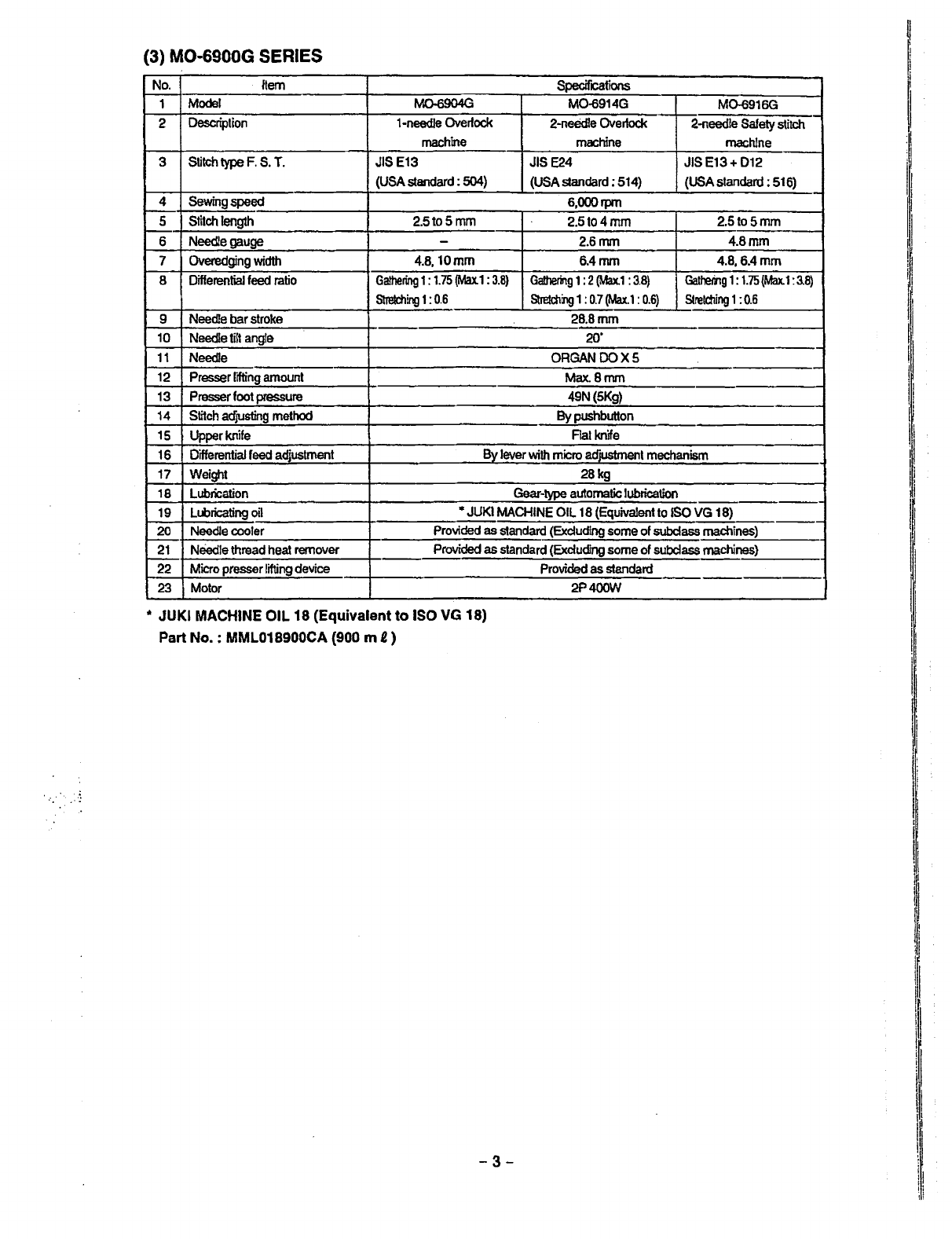

(3) MO-6900G SERIES

•••••••..•••••••..•••••••...••••••..••••..••••.•••••.•.•••.•....•.••...•••••...•.•••••.•.•.•.•••.•.•.•••.•.

3

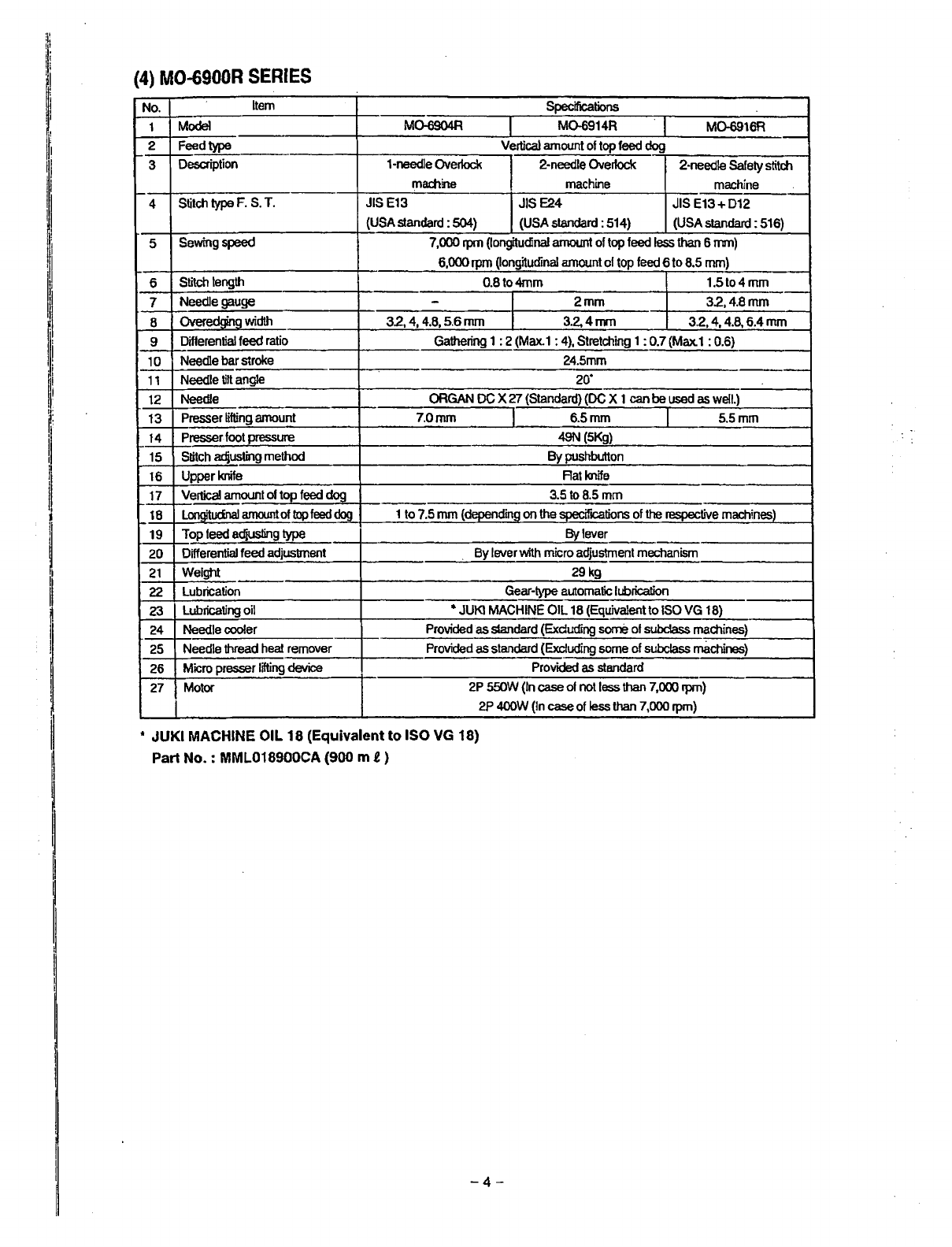

(4) MO-6900R SERIES •.••.•••••••••••.••••.•••.••••••••.•••••.......•.•..••..•••...•.......•.•.•••.•.••..•...•..••.....•.•.•...• 4

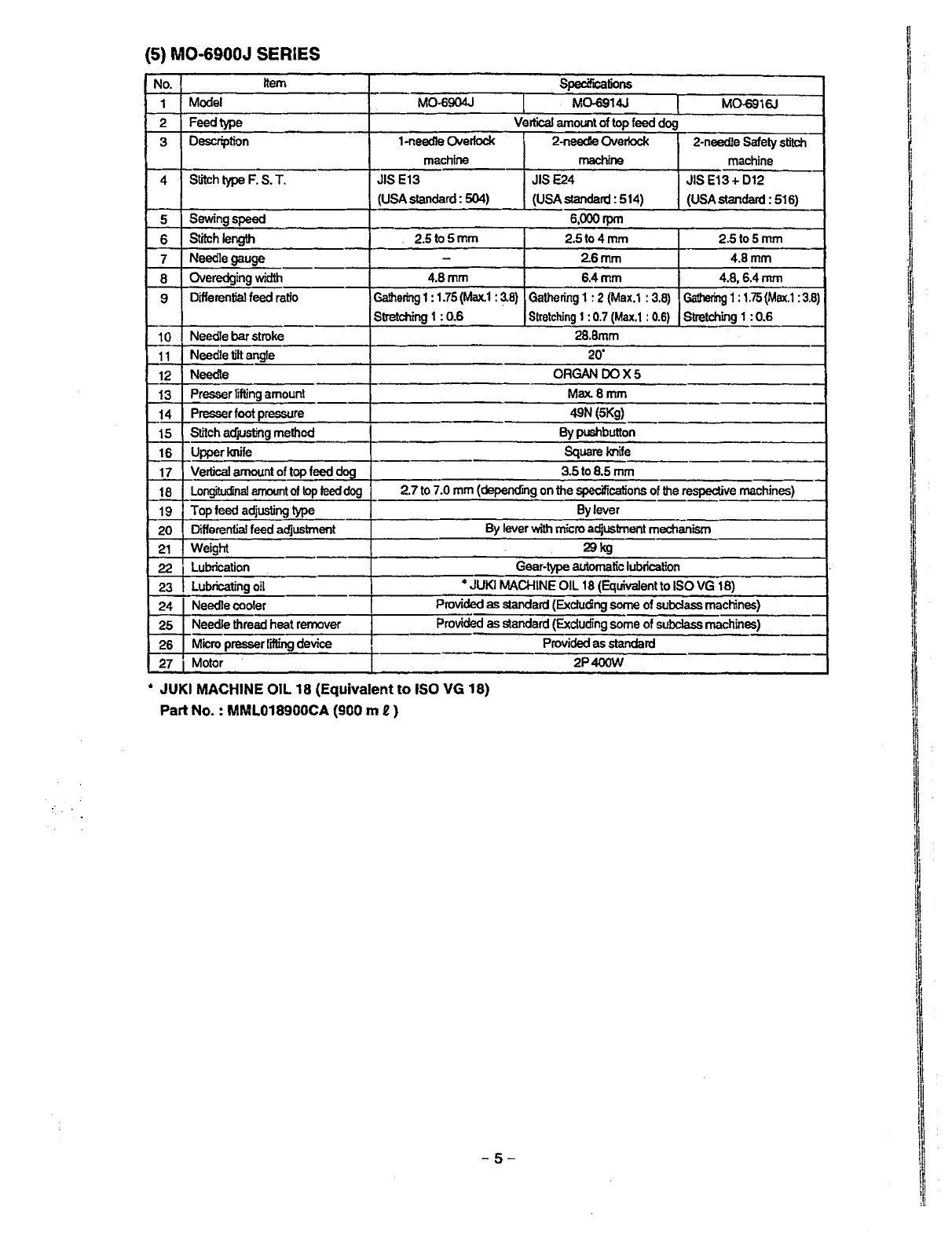

(5) MO-6900J SERIES.............................................................................................................5

2. MODEL NUMBERING SYSTEM ..••.••.•••..••••...••...•.•••••••.•••.•..•.••.•...•..•...••.•...•..... 6

3. STANDARD ADJUSTMENT ....••.•.•.•..•••..•.••••.••••••....•......•..•.•••.••......•.•.••.••.....•.. 8

(1)

Adjusting

the

needle

height

............................................................................................8

(2)

Positioning

the

throat

plate

............................................................................................ 8

(3)

Installing

position

of

the

needle Clamp .......................................................................

10

(4)

Adjusting

the

length

of

the

lower

looper

holder

(Applicable

only

to

MO-6.616S / MO-6916R, G, J

series)

...........................................

10

(5)

Adjusting

the

lower

looper

._

..........................................................................................

12

1)

Returning amount of the lowerlooper .................................................................................................... 12

2)

Clearance between the lowerlooperand the needle .............................................................................

12

(6)

Position

of

the

upper

looper

guide

...............................................................................

14

(7)

Positioning

the

upper

looper

holder

............................................................................

16

(8)

Positioning

the

upper

looper

........................................................................................

18

1) Height of the upper looper.................................................................................................

~

.................... 18

2) Longitudinal position

of

the upper looper................................................................................................ 18

(9)

Adjusting

the

double

chain

looper

· (Applicable

only

to

M0-6~

16S/MO-6916R, G, J series) ............................................... 20

1) Returning amount of the double chain looper.........................................................................................

20

2) Longitudinal motion {Avoid motion) ........................................................................................................

20

3) Clearance between the double chain looperand the needle ................................................................. 20

(10)

Adjusting

the

height

and

clearance

of

the

needle

guard

..............

~

.......................... 22

1) For 1-needle

or

2-needle overlock machine ...........................................................................................22

2) Forsafely stitch machine ........................................................................................................................ 22

(11)

Adjusting

the

height

of

the

feed

dog

.........................................................................

24

(12)

Adjusting

the

tillt

of

the

feed

dog

................................................................................

24

(13)

Adjusting

the

differential

feed

ratio

...........................................................................26

(14)

Longitudinal

position

of

the

feed

dog

.......................................................................

26

(15)

Adjusting

the

presser

foot

..........................................................................................28

1) Adjusting the tilt of the presser foot ........................................................................................................

28

2) Adjusting the micro-lifting mechanism of the presserfoot ......................................................................

28

(16)

Positioning

the

upper

knife

arm

shaft

.......................................................................

30

(17)

Positioning

the

upper

and

lower

knives,

and

available

overedge

widths

.............. 30

1)

lower

knife .............................................................................................................................................30

2) Upper knife .............................................................................................................................................30

3) Overdging width......................................................................................................................................30

(18)

Resharpening

of

the

knife

..........................................................................................32

(19)

Position

of

the

thread

cam

(Applicable

only

to

MO-6~16~

series)

........................

32

1) Adjustment of the thread cam.............................................:................................................................... 32

2) Adjusting looperthread cam thread guides A and B and the looper thread cam nail............................. 32

From the Library of Superior Sewing Machine & Supply LLC