i

CONTENTS

1. SPECIFICATIONS.................................................................................................................... 1

2. INSTALLATION........................................................................................................................ 1

3. ADJUSTING THE BELT TENSION.......................................................................................... 2

4. INSTALLING THE SYNCHRONIZER SUPPORT ROD........................................................... 3

5. ATTACHING THE BELT COVER............................................................................................. 3

6. INSTALLING THE KNEE SWITCH.......................................................................................... 4

7. INSTALLING THE AIR DRIVE UNIT........................................................................................ 4

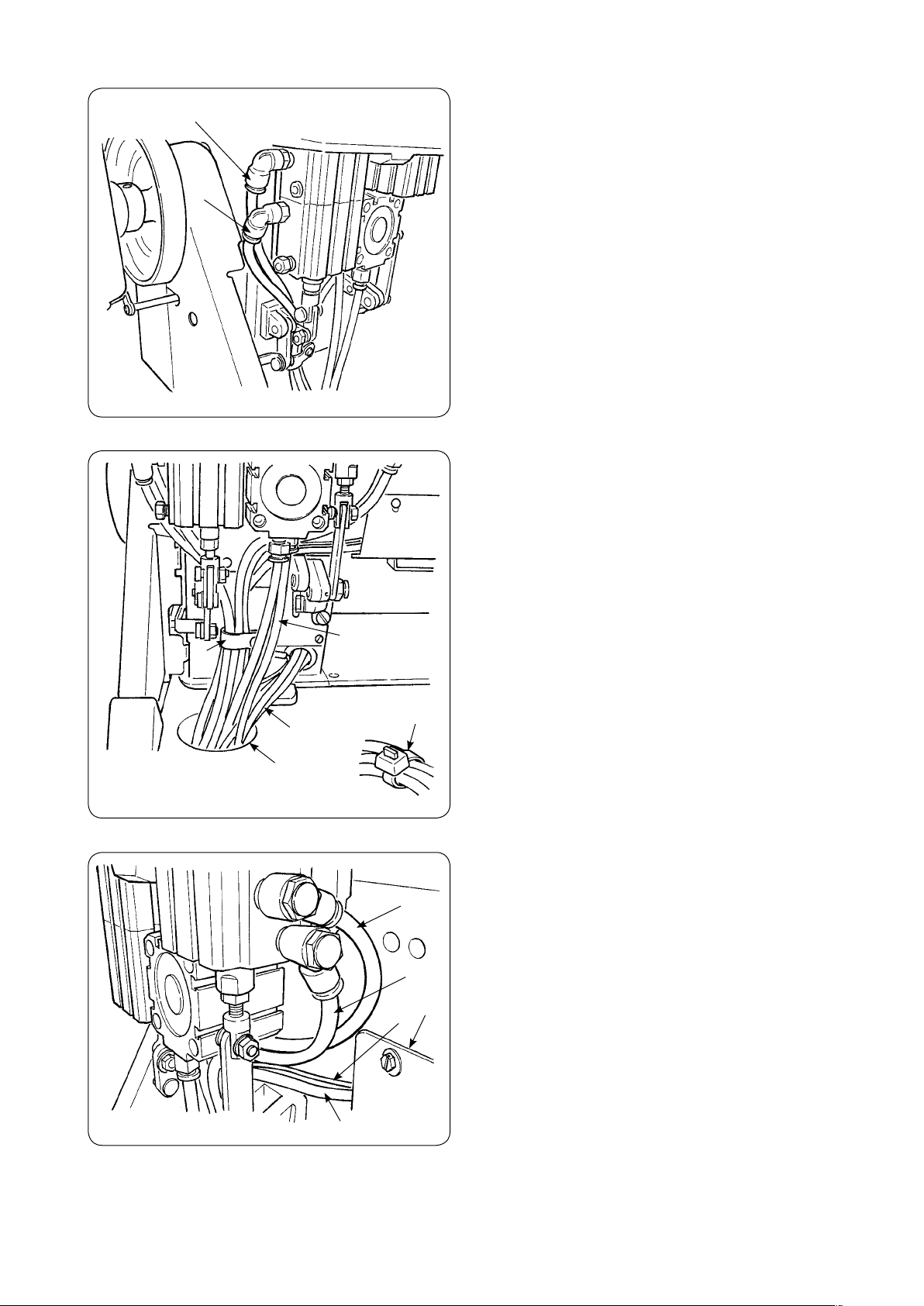

(1)Installing the air control unit ...............................................................................................................4

(2)Connecting the air hose....................................................................................................................... 5

(3)Adjusting the air pressure ................................................................................................................... 6

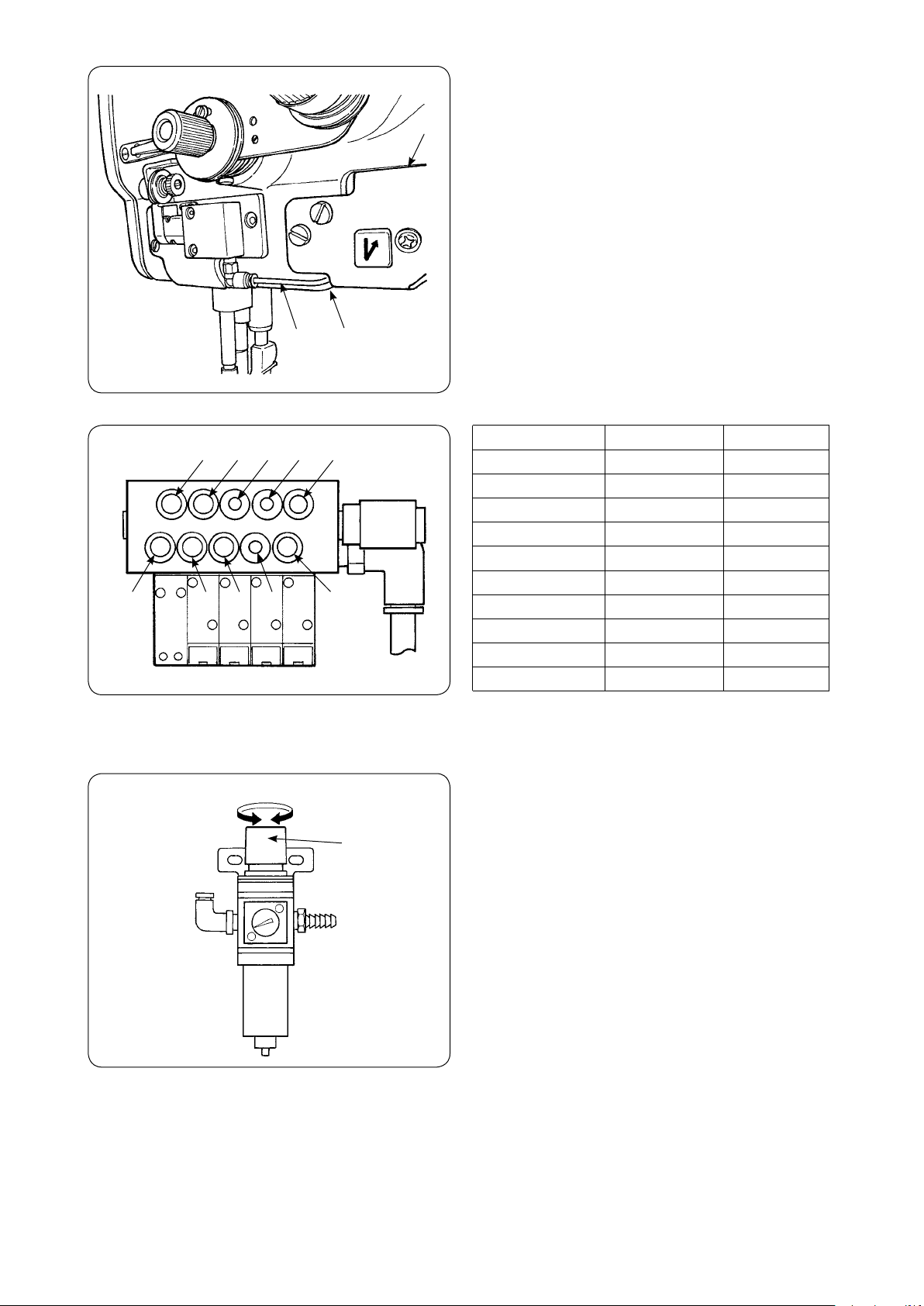

8. INSTALLING THE THREAD STAND....................................................................................... 7

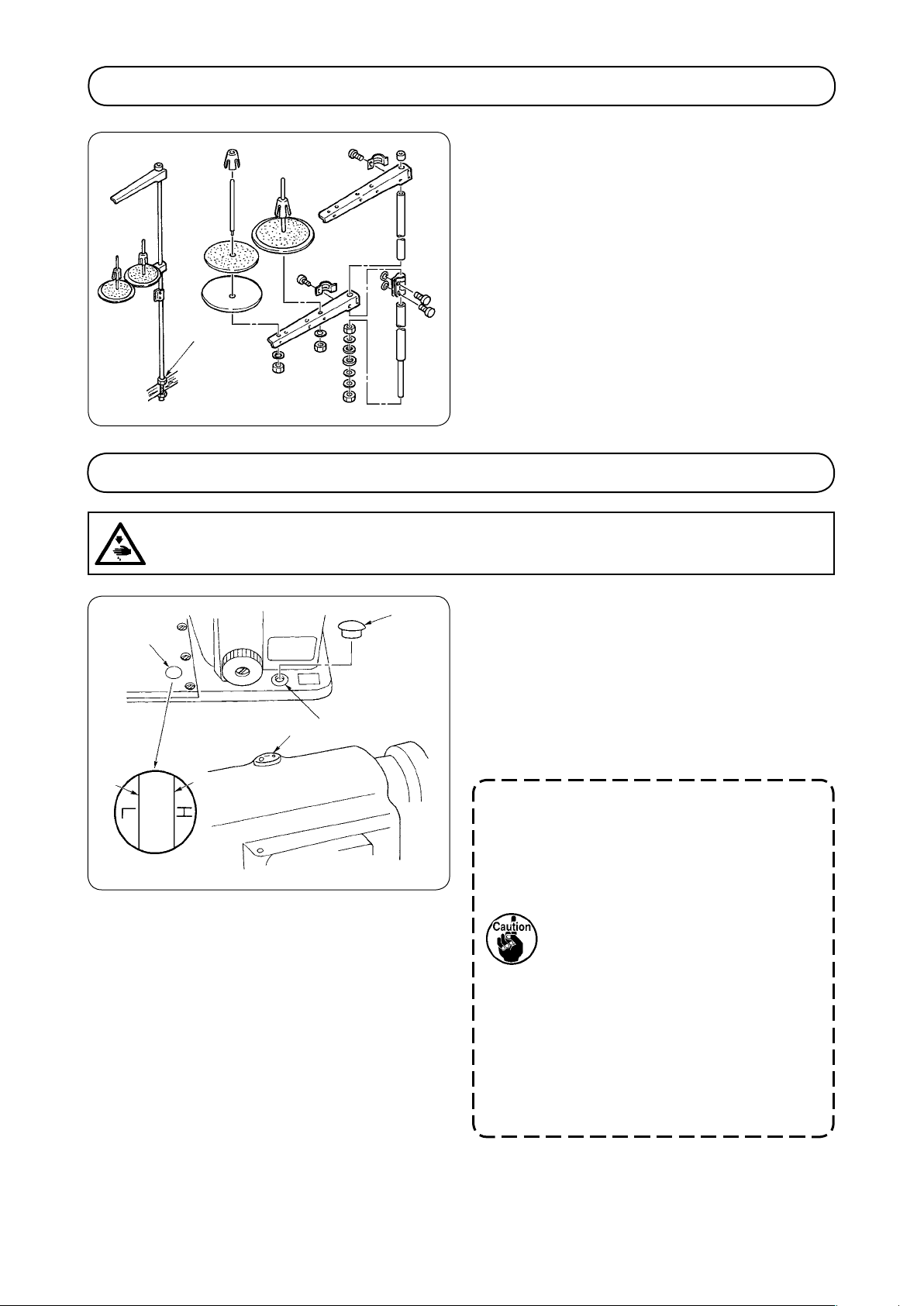

9. LUBRICATION ......................................................................................................................... 7

10. ATTACHING THE NEEDLE ................................................................................................... 9

11. ATTACHING/REMOVING THE BOBBIN ............................................................................... 9

12. THREADING THE HOOK .................................................................................................... 10

13. INSTALLING THE THREAD GUIDE.................................................................................... 10

(1)Installing the needle thread guide rod.............................................................................................. 10

(2)Installing the bobbin winder thread guide ....................................................................................... 10

14. WINDING A BOBBIN ........................................................................................................... 11

15. ADJUSTING THE AMOUNT OF OIL IN THE HOOK .......................................................... 11

16. THREADING THE MACHINE HEAD................................................................................... 12

17. ADJUSTING THE STITCH LENGTH................................................................................... 13

18. THREAD TENSION............................................................................................................... 13

(1)Adjusting the length of thread remaining after thread trimming ...................................................13

(2)Adjusting the needle thread tension................................................................................................. 13

(3)Adjusting the bobbin thread tension ................................................................................................ 13

19. THREAD TAKE-UP SPRING ............................................................................................... 14

(1)When you want to change the stroke of the spring : ......................................................................14

(2)When you want to change the tension of the spring : ....................................................................14

20. HAND LIFTER / HANDHEBEL............................................................................................ 14

21. ADJUSTING THE PRESSURE OF THE PRESSER FOOT ................................................ 14

22. NEEDLE-TO-HOOK RELATION.......................................................................................... 15

23. ADJUSTING THE HOOK NEEDLE GUARD ....................................................................... 15

24. ADJUSTING THE BOBBIN CASE OPENING LEVER........................................................ 16