CONTENTS

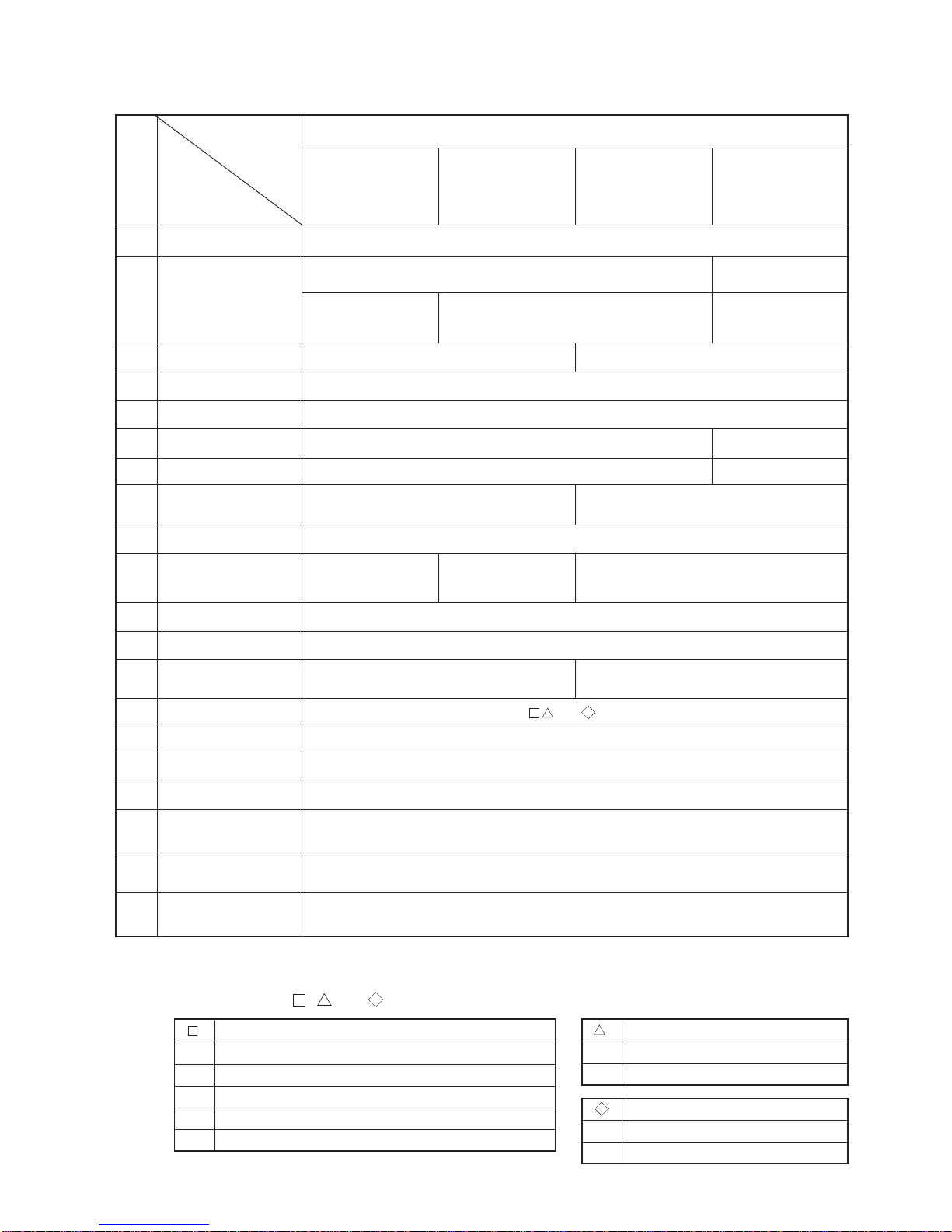

1. Specifications ............................................................................................... 1

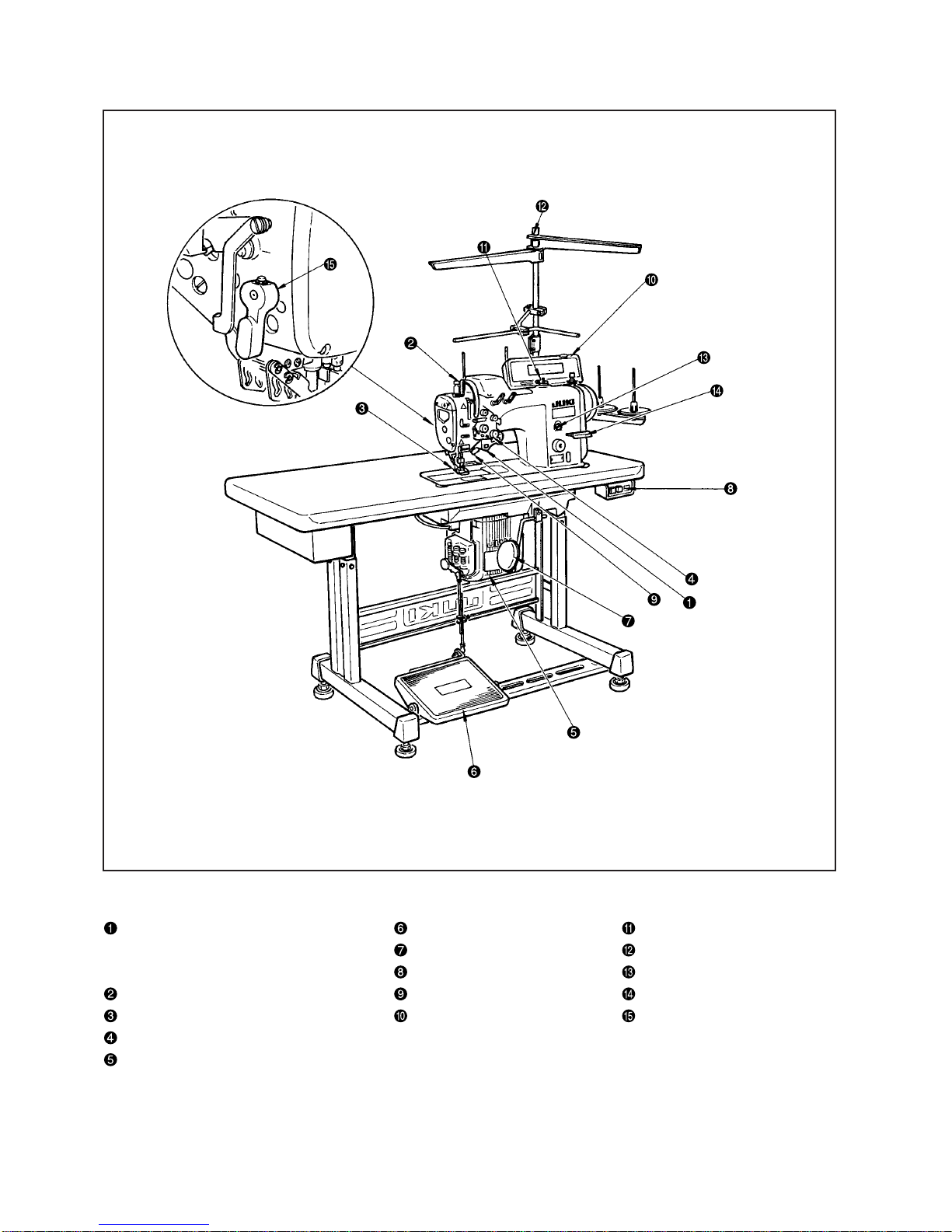

2. Name of each component ............................................................................ 2

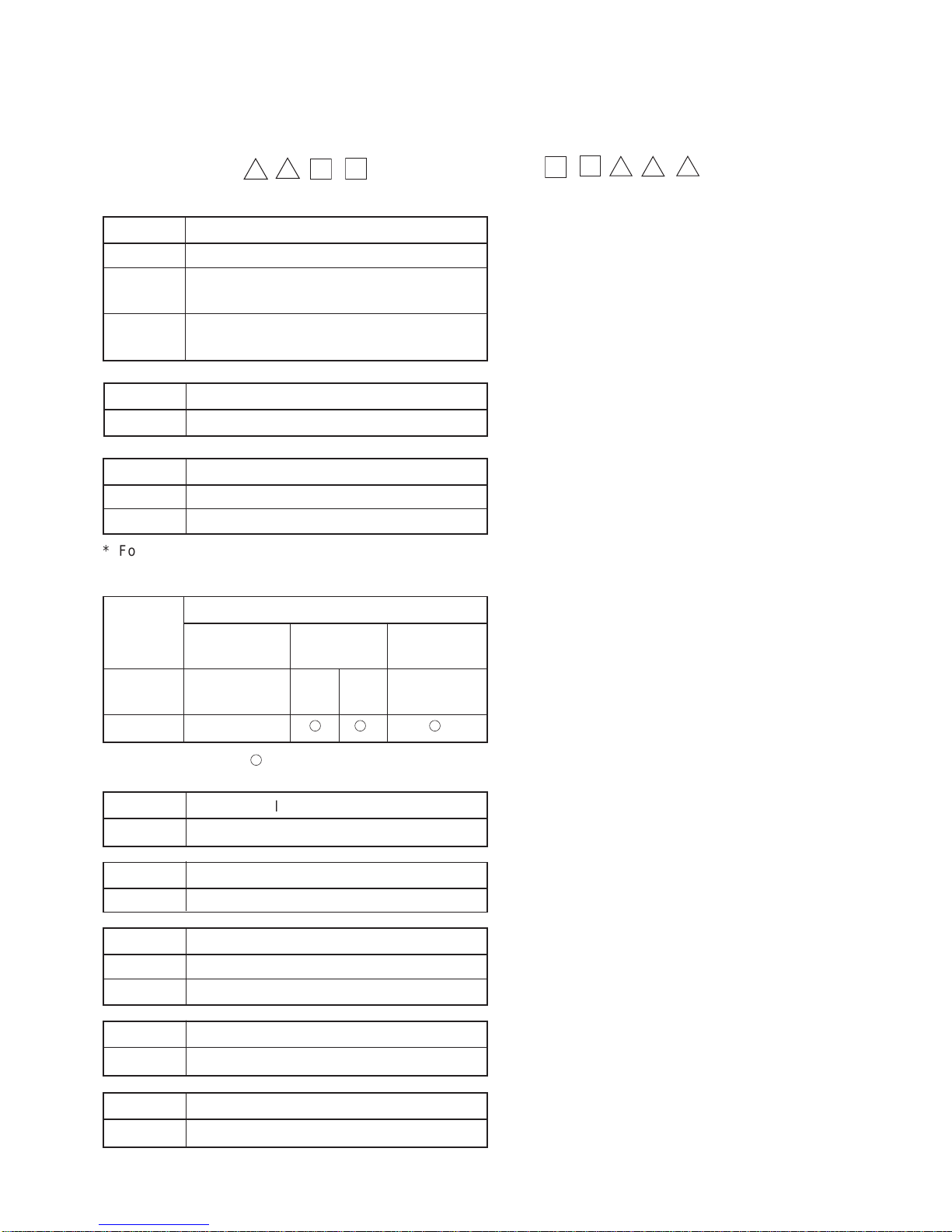

3. Model numbering sysytem .......................................................................... 3

(1) LH-4128 (without a thread trimmer) ..........................................................................3

(2) LH-4128-7•LH-4168-7•LH-4188-7 (with a thread trimmer)........................................4

4. Special notes for safe operation ................................................................. 5

5. Standard adjustment .................................................................................... 8

(1) Needle bar and feed dog ............................................................................................8

1) Initial position of the needle bar..........................................................................................................8

2) Adjustment of the right and left feed dog positions, height, and gradient.........................................10

3) Needle bar height .............................................................................................................................12

4) Needle clamp....................................................................................................................................14

5) Needle entry .....................................................................................................................................14

(2) Timing between the needle and the hook...............................................................16

1) Lift of the needle bar .........................................................................................................................16

2) Clearance between the needle and the blade point of the hook ......................................................16

3) Position of the needle and the blade point of the hook.....................................................................16

(3) Initial position of the bobbin case opening lever ..................................................18

(4) Standard adjusting position for the inner hook guide arm shaft.........................18

(5) Clearance between the throat plate and the bobbin case stopper ......................20

(6) Relation between the main shaft and the lower shaft ...........................................22

(7) Lubrication ................................................................................................................24

1) Lubrication system............................................................................................................................24

2) How to clean the filter section...........................................................................................................24

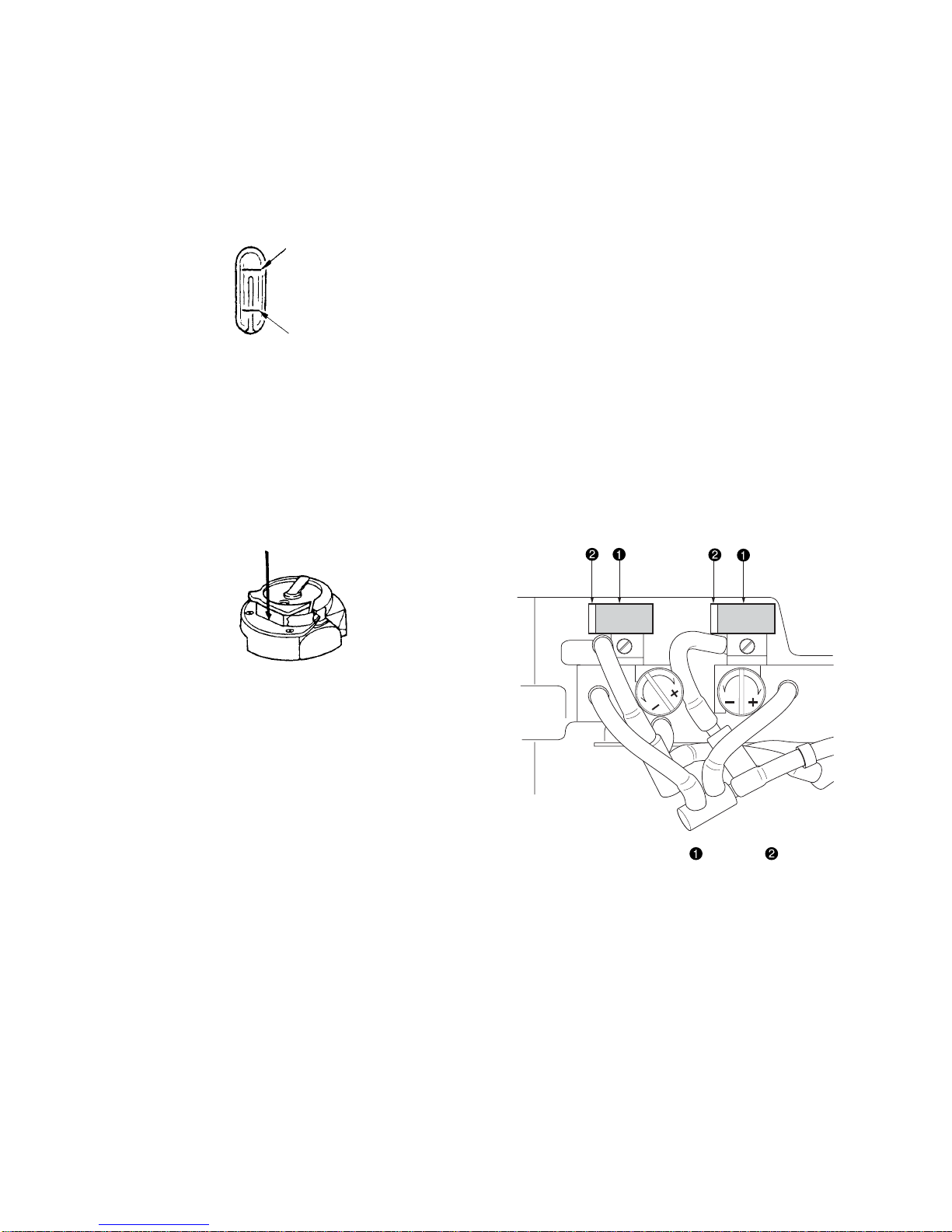

3) Hook oil amount................................................................................................................................24

4) Oil in the feed box.............................................................................................................................26

5) Replacement of the hook shaft oil wick ............................................................................................26

6) Replenishing grease to the specified places (for LH-4168-7, LH-4188-7 only) ................................28

(8) Forward and reverse stitch pitches ........................................................................32

(9) Adjusting the needle stop position.........................................................................34

1) Needle-up stop position of the sewing machine ...............................................................................34

2) Needle-down stop position of the sewing machine ..........................................................................34

(10) Disc release changeover for lap lifter.....................................................................36

(11) Needle bar stroke adjustment (for LH-4168-7, LH-4188-7 only) ...........................38

(12) Thread trimming device ...........................................................................................40

1) Moving knife position ........................................................................................................................40

2) Adjusting the height of the counter knife...........................................................................................40

3) Adjusting the thread presser spring ..................................................................................................42

4) Position of the thread trimming cam and the thread trimming timing ...............................................44

5) Clearance between the thread trimming cam and the thread loosening arm ...................................44

6) Adjustment of thread tension release ...............................................................................................46