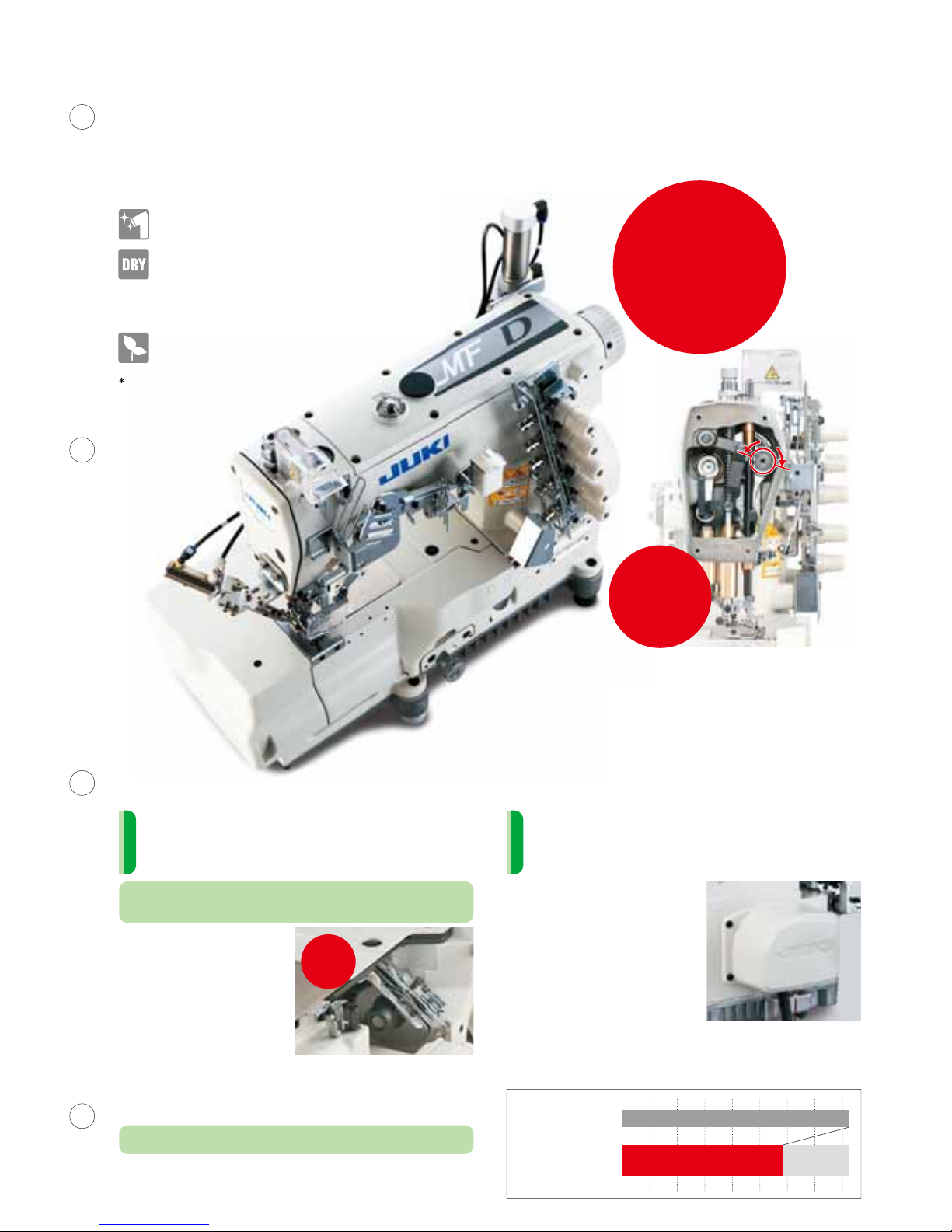

JUKI's dry-head technology

protects sewing products from being stained with oil.

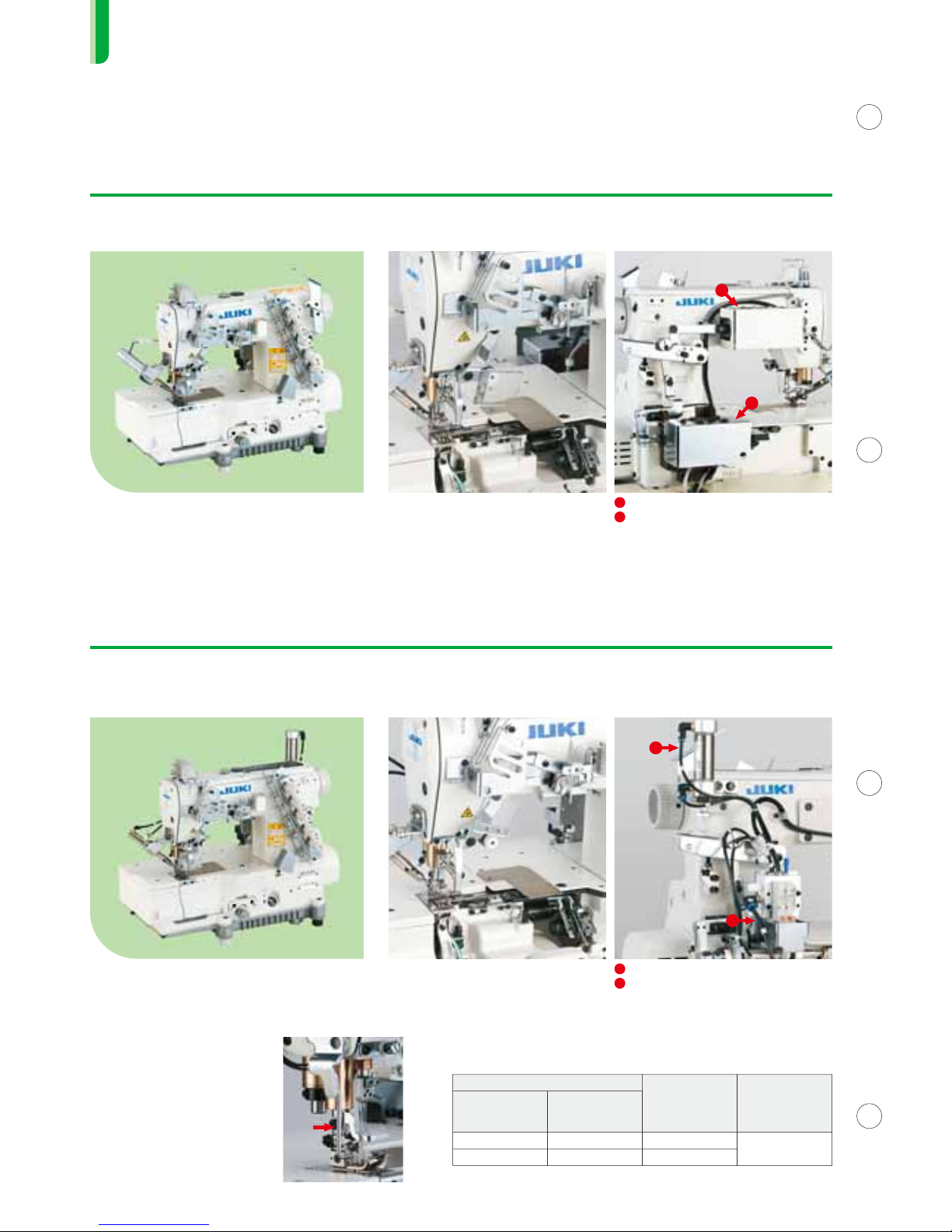

In the case of looper thread

breakage, the looper thread

twining prevention mechanism is

activated to trim the looper thread

before the thread twines on the

looper thread cam. In this way, the

looper thread twining prevention

mechanism prevents the looper

thread from twining on the looper

thread cam. In addition, the looper thread cam, which has been

incorporated in the sewing machine, has been changed so that it is

mounted outside of the sewing machine. The externally-mounted looper

thread cam promises improved maintainability.

As a result of the commonality of components, commercially-available

components (presser foot, throat plate and needle clamp) are now

applicable and easily obtainable.

With the excellent functions inherited from the MF-7500 Series, the MF-7500D is provided

with a dry frame mechanism to eliminate the cause of oil stains. Stain removing work or

re-sewing work is substantially reduced by protecting sewing products from being

stained with oil, thereby improving the quality of finished products.

The frame no longer requires oiling.

Dry-head technology has materialized

a frame which does not need oiling.

Environmental consciousness

Dichlorofluoroethane (HCFC-141), which is generally used in

oil stain cleaning fluid, is included in those chemicals which

need to be reduced, as it is a substances that can harm the

ozone layer.

Since oil stains on sewing products are reduced, the quantity

of the use of stain remover generally used in sewing plants

can be reduced.

The needle bar mechanism and spreader mechanism have been applied with a

special surface treatment.

JUKI's unique special grease is used for lubrication. Grease-filled bearings have

been adopted for the crank rod. These allow the machine's frame mechanism to

demonstrate outstanding durability without being oiled.

Unlike the conventional models, the oiling mechanism inside the frame has been eliminated.

As a result, oil does not leak from the needle bar, presser bar or spreader shaft.

Simplified maintenance mechanism

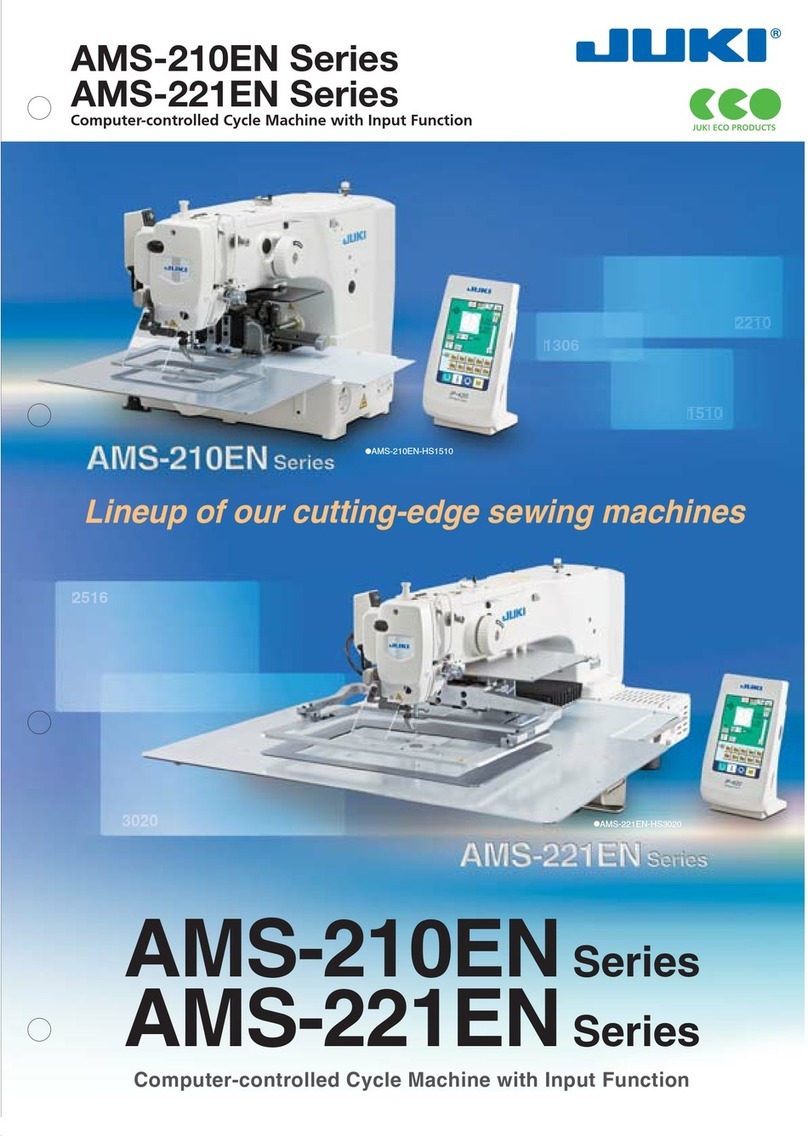

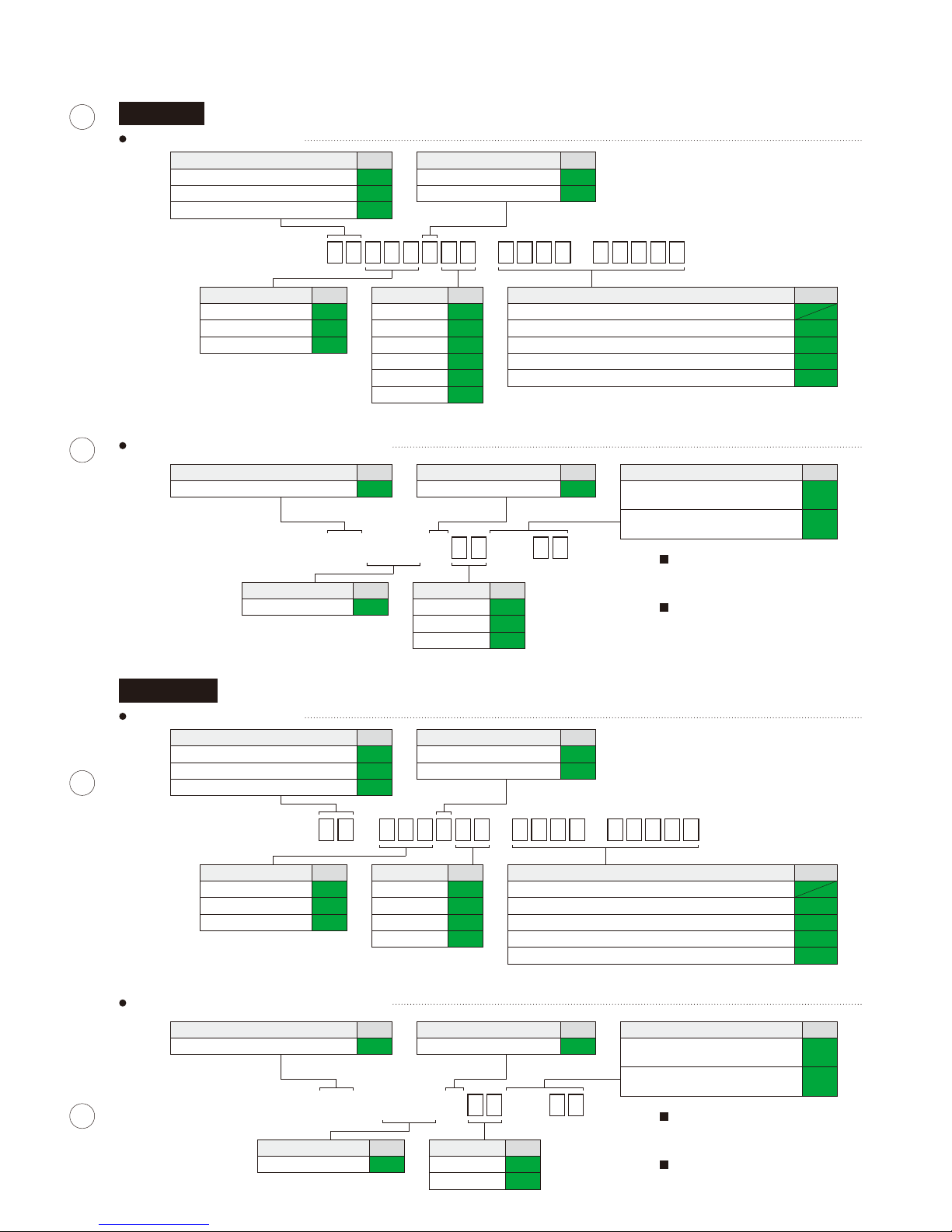

All of the sewing machines with

a thread trimmer are provided

with a direct-drive motor.

By changing over the needle bar stroke, penetrating force of the

needle as well as thread tension to fit heavy-weight materials

(fleece, blankets) can be obtained. The needle bar stroke can be

changed by adjusting the eccentric pin. (Changing of parts is not

required. Factory-set at the time of delivery: 31mm; for sewing

heavy-weight materials: 33mm)

Needle bar stroke conversion mechanism

The direct-drive motor system has

been adopted by all of the sewing

machines with a thread trimmer. As a

result, the sewing machine starts up

swiftly and promises increased stop

accuracy, thereby demonstrating

improved responsiveness. In addition,

the machine is no longer provided with

a V-belt. This means that the adoption

of the direct-drive motor is also

effective in the elimination of belt shavings. Power is directly transmitted

from the motor to the sewing machine, thereby contributing to reduced

power consumption. (This sewing machine reduces power consumption

by 29% as compared with the conventional models.)

MF-7723/UT31/SC510

MF-7523/UT37/SC921B/CP18B

Servomotor

Direct-drive motor

The semi-dry

head sewing machine

increases its sewing

speed to

5,000

sti/min

head type sewing

machine has been

added.

A semi-dry

The

world's

first

Commercially-available gauge components

are applicable with no additional work.

The looper thread twining prevention mechanism

has been improved and is provided as standard

for the sewing machine.

29%

Power

consumption

Reduced by