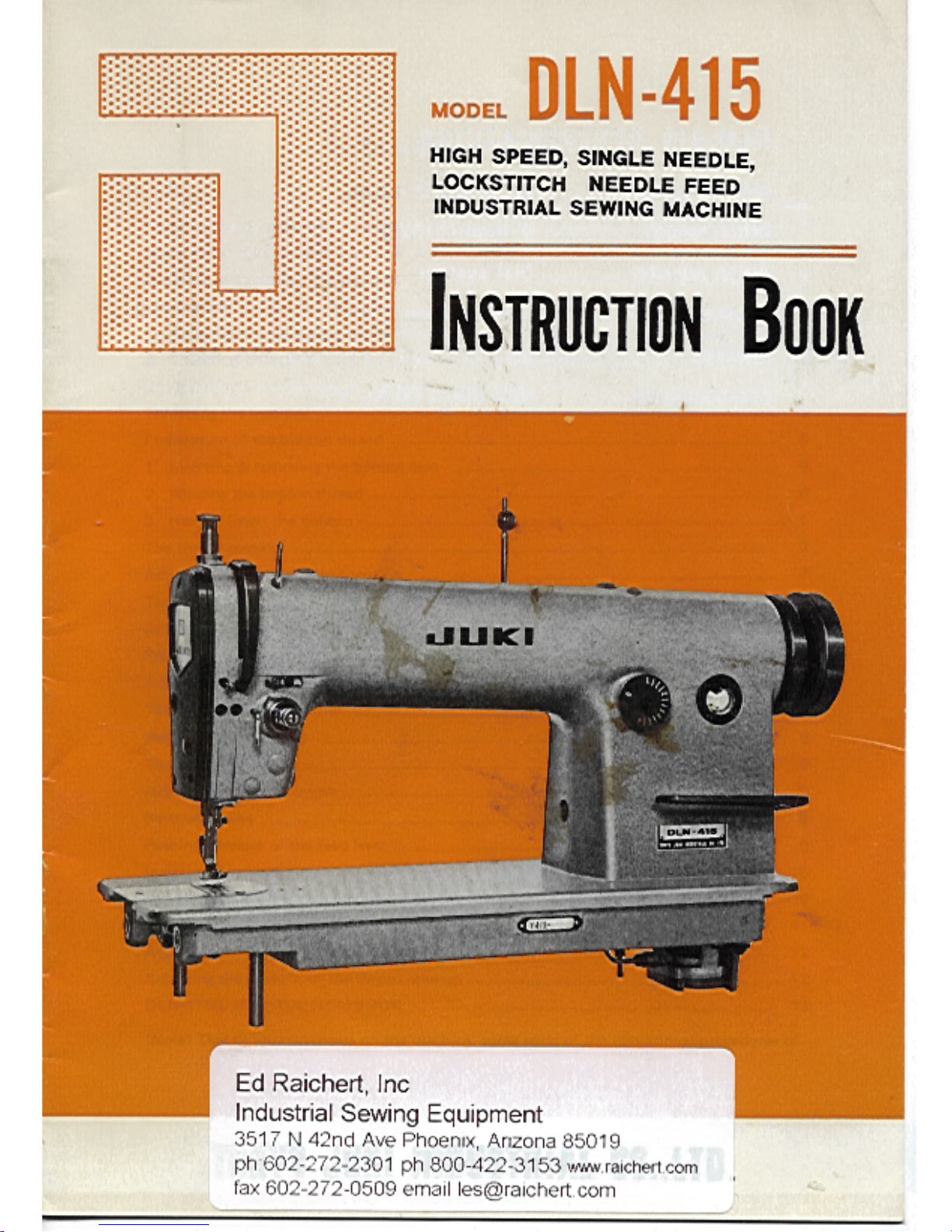

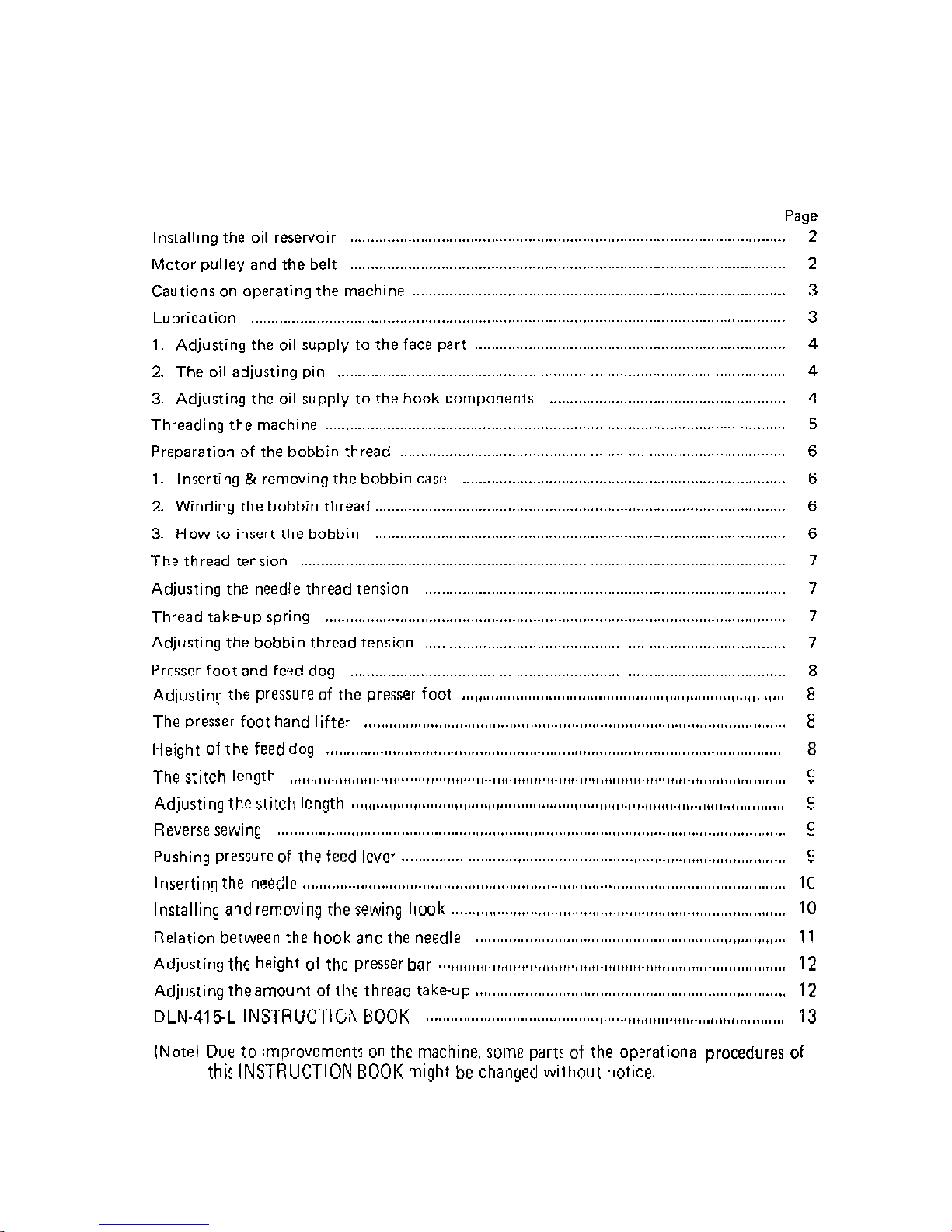

JUKI DLN-415 User manual

Other JUKI Sewing Machine manuals

JUKI

JUKI LU-2220N-7 User manual

JUKI

JUKI LZ-2290C/X73257 User manual

JUKI

JUKI MF-7900 Series User manual

JUKI

JUKI MF-7800 User manual

JUKI

JUKI CP-160 User manual

JUKI

JUKI AK118 User manual

JUKI

JUKI LS-1340 User manual

JUKI

JUKI LU-2810-6 User manual

JUKI

JUKI ACF-172-1790 User manual

JUKI

JUKI HZL - 353Z Series User manual

JUKI

JUKI MO-6704DA User manual

JUKI

JUKI MB-1800 series Quick start guide

JUKI

JUKI DNU-1541-7 User manual

JUKI

JUKI DDL-9000B User manual

JUKI

JUKI AMB-289 Quick start guide

JUKI

JUKI DU-140 User manual

JUKI

JUKI DDL-9000B User manual

JUKI

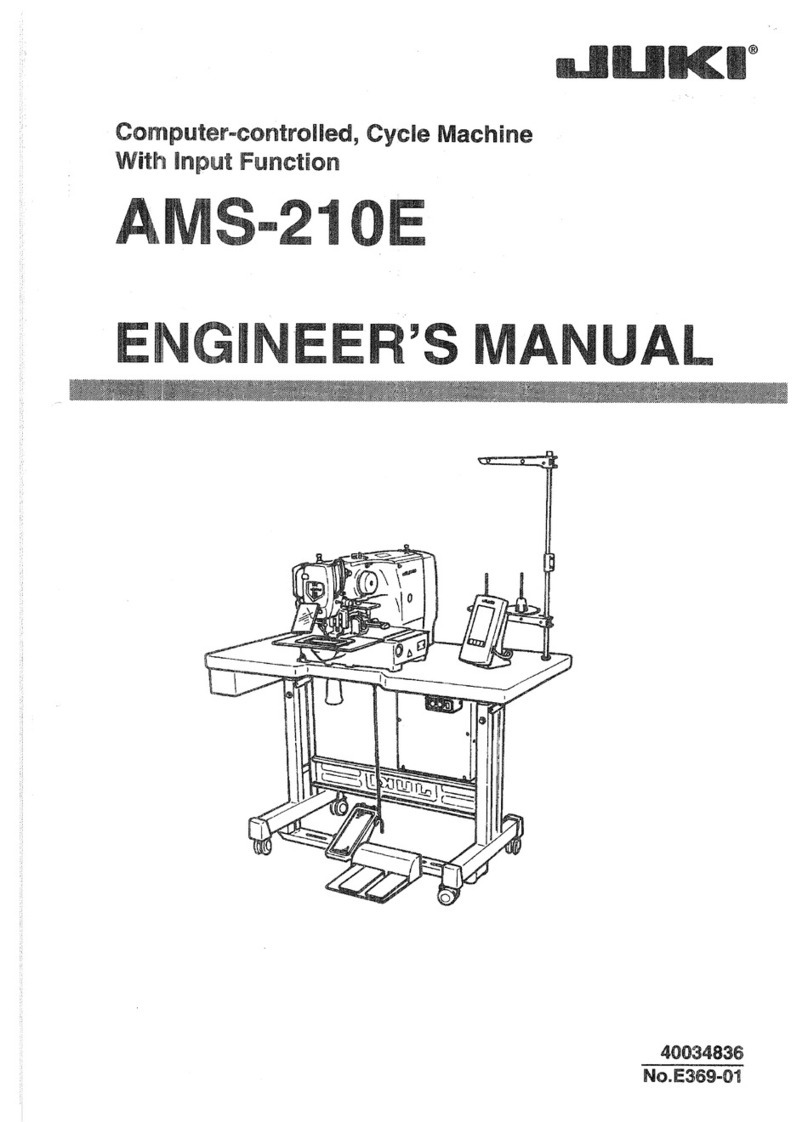

JUKI AMS-210E Series Quick start guide

JUKI

JUKI MF-7800/UT25 User manual

JUKI

JUKI LBH-781 User manual