PREFACE

This Engineer's Manual is written for the technical personnel who are responsible for the service and maintenance

of

the sewing machine. This manual describes "Adjustment Procedure", "Results

of

Improper Adjustment", and other

functions which are not covered by the Instruction Bookintended for the maintenance personnel and sewing operators

at

a sewing factory.

All personnel engaged

in

repair

of

TSH-411 and TSU-471 are required to carefully read Section 2 "Standard Adjustment"

which contains important information on the maintenance

of

TSH-411 and TSU-471.

The "Standard Adjustment" consists

of

two parts; the former part presents illustration and simplified explanation for

the convenience

of

reconfirmation

of

the required adjustment values in carrying out actual adjustment after reading

this manual once; and the latter part provides "Results

of

ImproperAdjustment" in which sewing and/or mechanical

failures, and the correcting procedures are explained for those persons who perform such adjustment forthe first time.

It is advisable to use "TSH-411 and TSU-471 Parts Book" together with this Engineer's Manual.

CONTENTS

1. SPECIFICATIONS ......................••.•.......•.......••••...•.•.........••......••....................... 1

2. ADJUSTMENTS •...•........................•.•.••••............................................•..............2

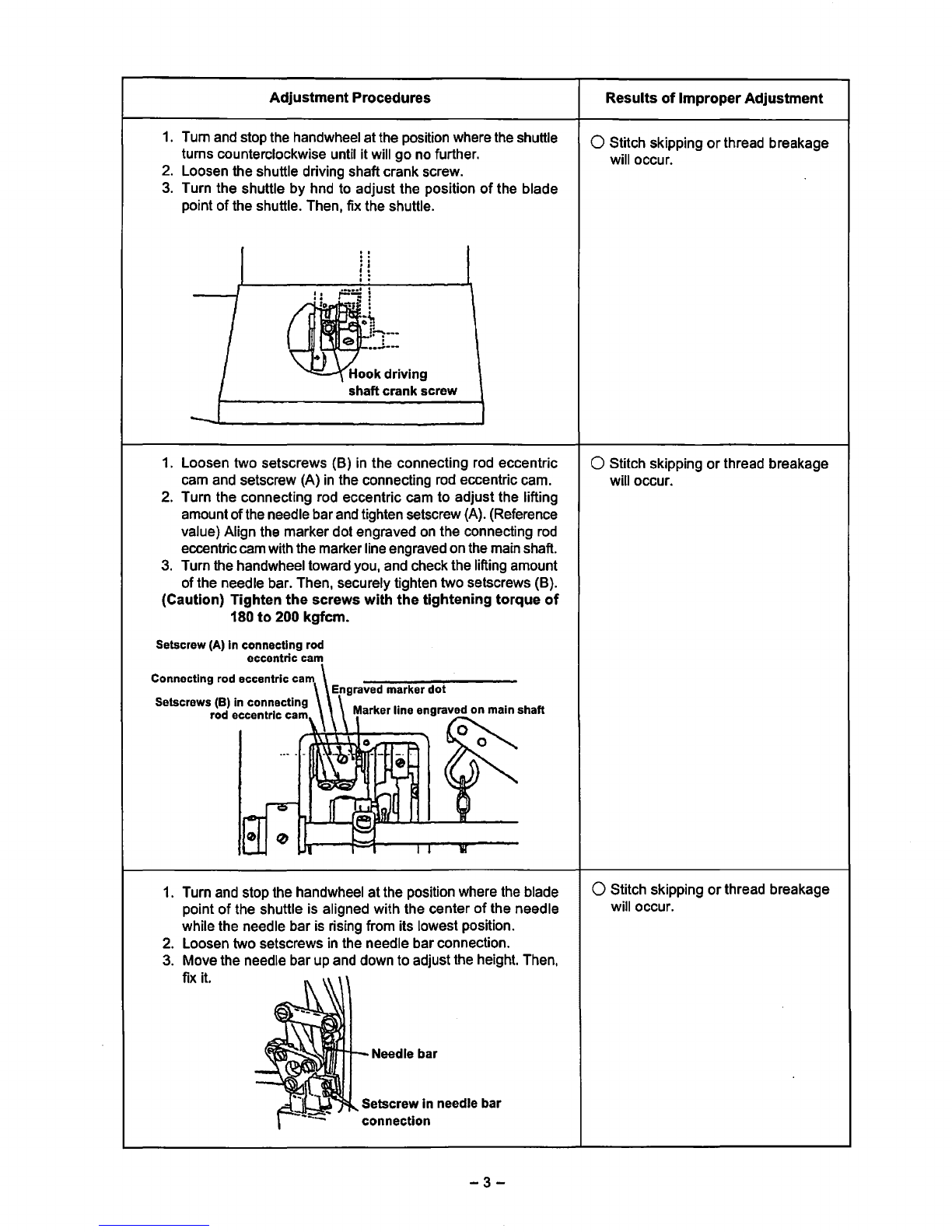

(1) The position

of

the shuttle when

it

is recessed

most

.......••...•.........•.........••......•...•..... 2

(2) Needle-to-shuttle timing......•.•••....•...•....•..•..•......................•............................................2

(3)

Height

of

the needle bar......................................•................................................•..........2

(4)

Clearance between the needle and the shuttle............................................................. 4

(5)

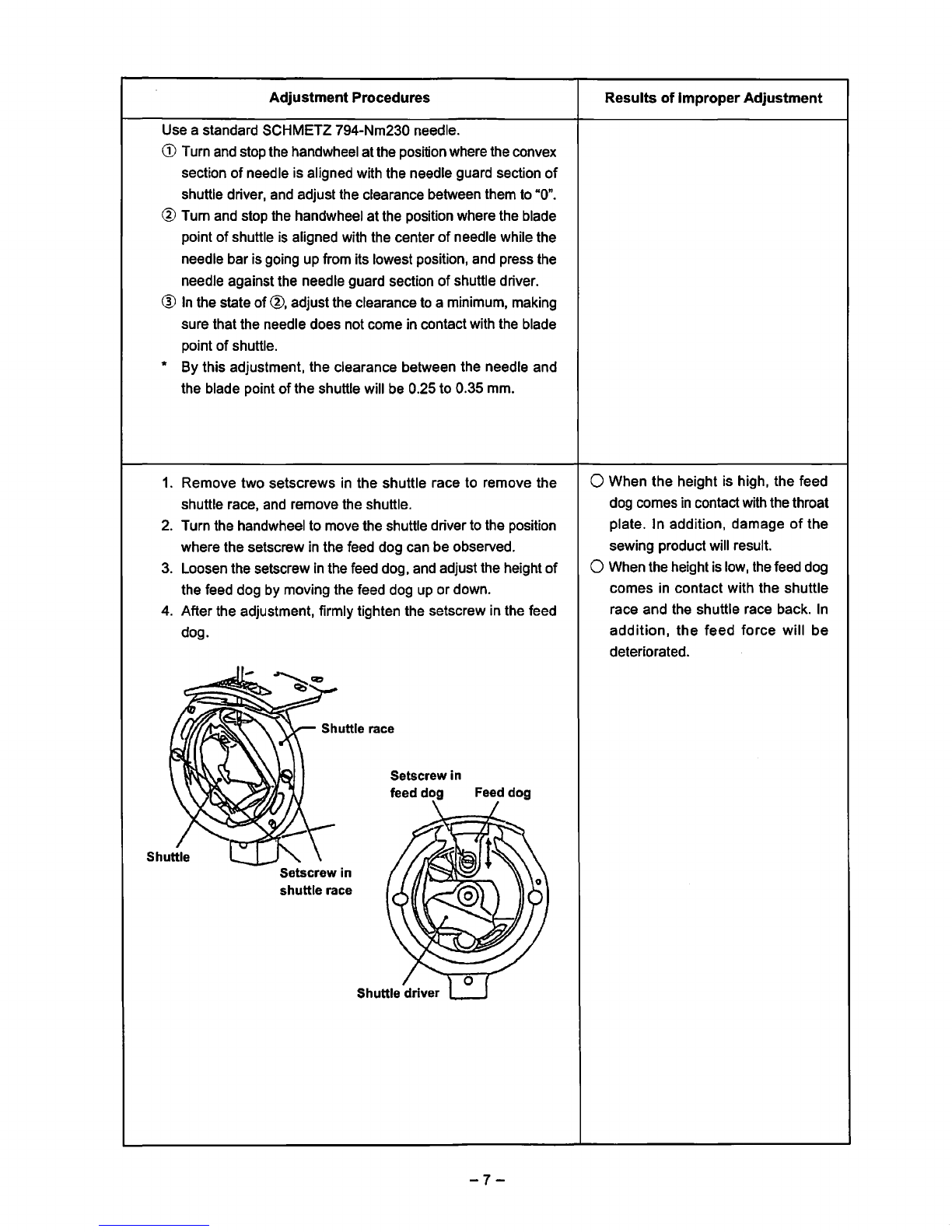

Clearance between the needle and the shuttle driver.................................................. 4

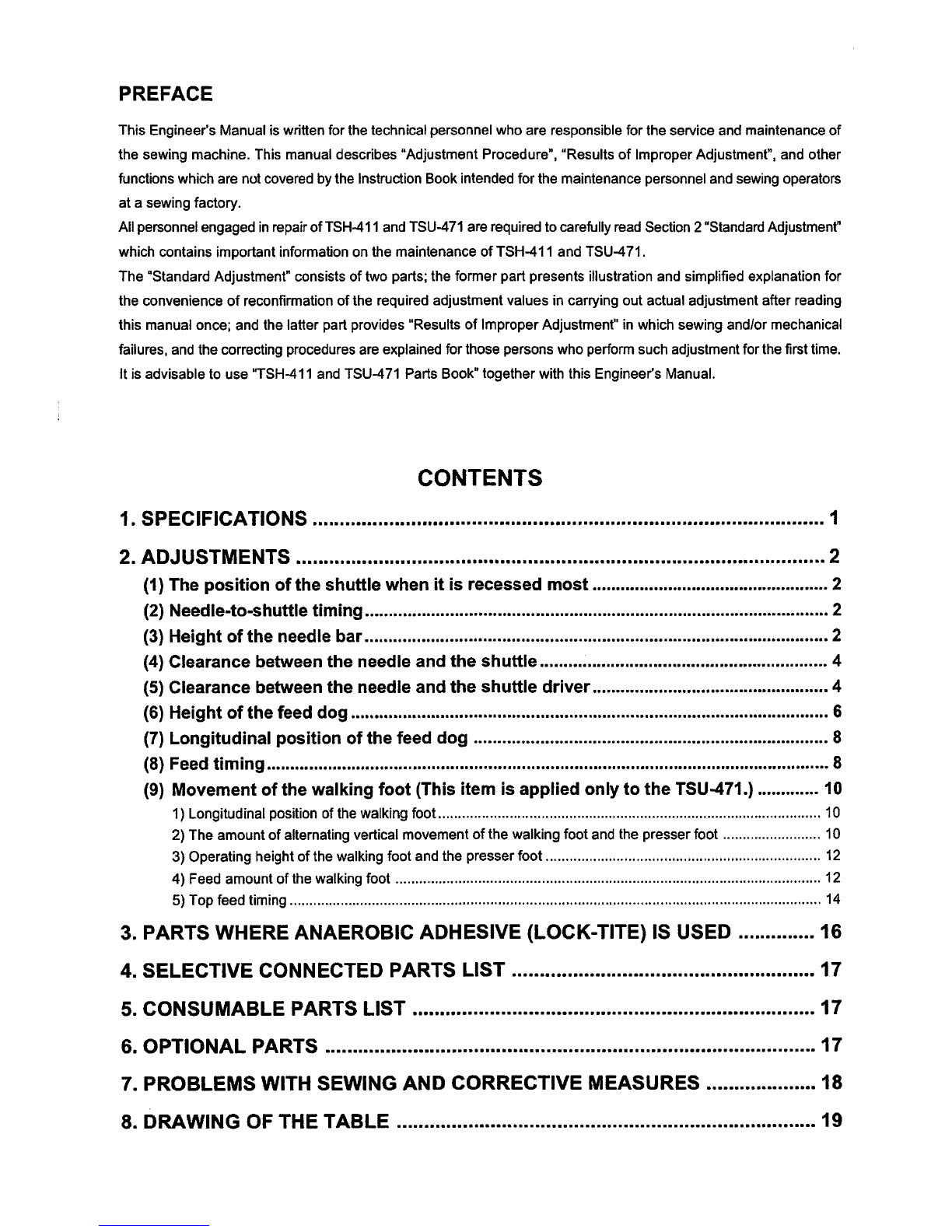

(6) Height

of

the feed dog•...•••.•••..•..........••......•.•...................................................•.............. 6

(7)

Longitudinal position

of

the feed dog ......•.................................................................... 8

(8)

Feed

timing

..................................................•....................................................................8

(9)

Movement

of

the walking

foot

(This item

is

applied only

to

the

TSU-471.) .............

10

1) Longitudinal position

of

the walking foot................................................................................................. 10

2) The amount

of

alternating vertical movement

of

the walking foot and the presserfoot ......................... 10

3) Operating height

of

the walking foot and the presser foot ...................................................................... 12

4) Feed amount

of

the walking foot ............................................................................................................ 12

5) Top feed timing ....................................................................................................................................... 14

3. PARTS WHERE ANAEROBIC ADHESIVE (LOCK-TITE) IS USED .............. 16

4. SELECTIVE CONNECTED PARTS LIST ....................................................... 17

5.

CONSUMABLE PARTS LIST •.•••..•...........................................••..••••••••.•........ 17

6. OPTIONAL PARTS .......••.•••••••••..••.......•.•••.••......•••...••.•.....•••••.••••••......•..........• 17

7. PROBLEMS WITH SEWING AND CORRECTIVE MEASURES .................... 18

8. DRAWING OF THE TABLE .....•.••.•......................................................•.••••..... 19

From the library of: Superior Sewing Machine & Supply LLC