CONTENTS

1. SPECIFICATIONS............................................................................................................ 1

1-1. Specications of the sewing machine head ..................................................................... 1

1-2. Specications of the control box....................................................................................... 1

2. SET UP............................................................................................................................. 2

2-1. Drawing of table................................................................................................................... 2

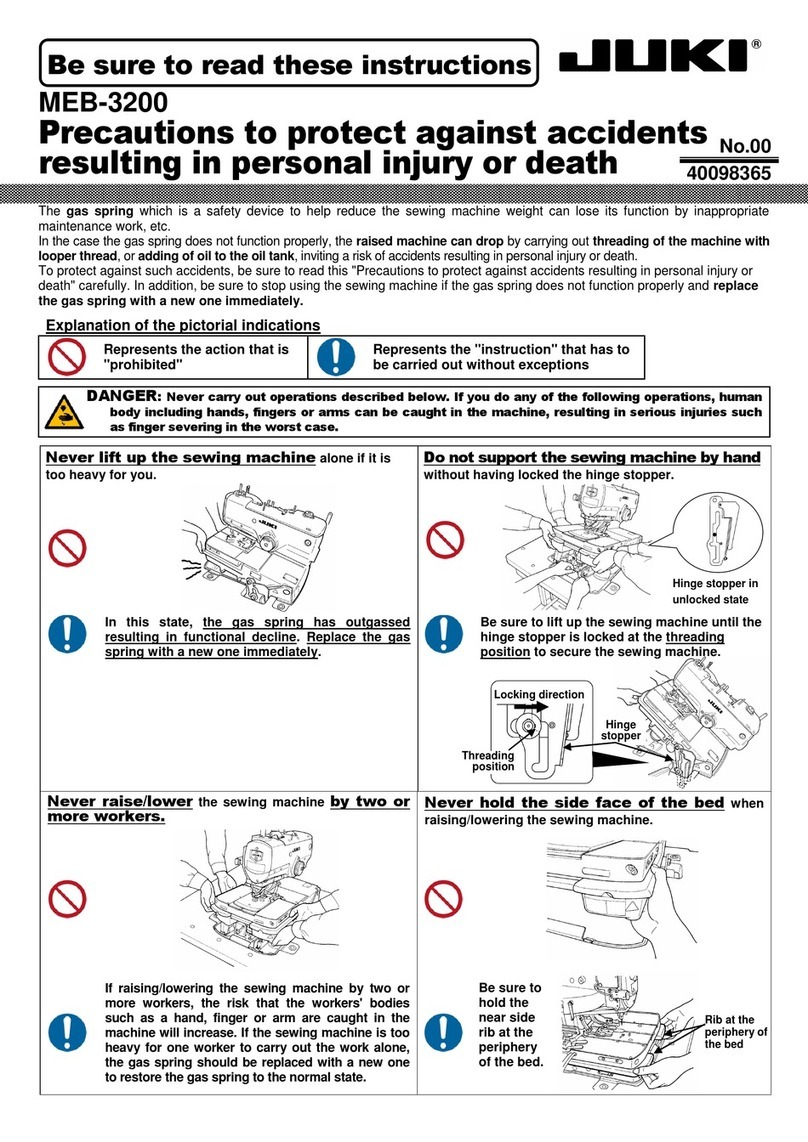

2-2. Cautions when setting up the sewing machine................................................................ 3

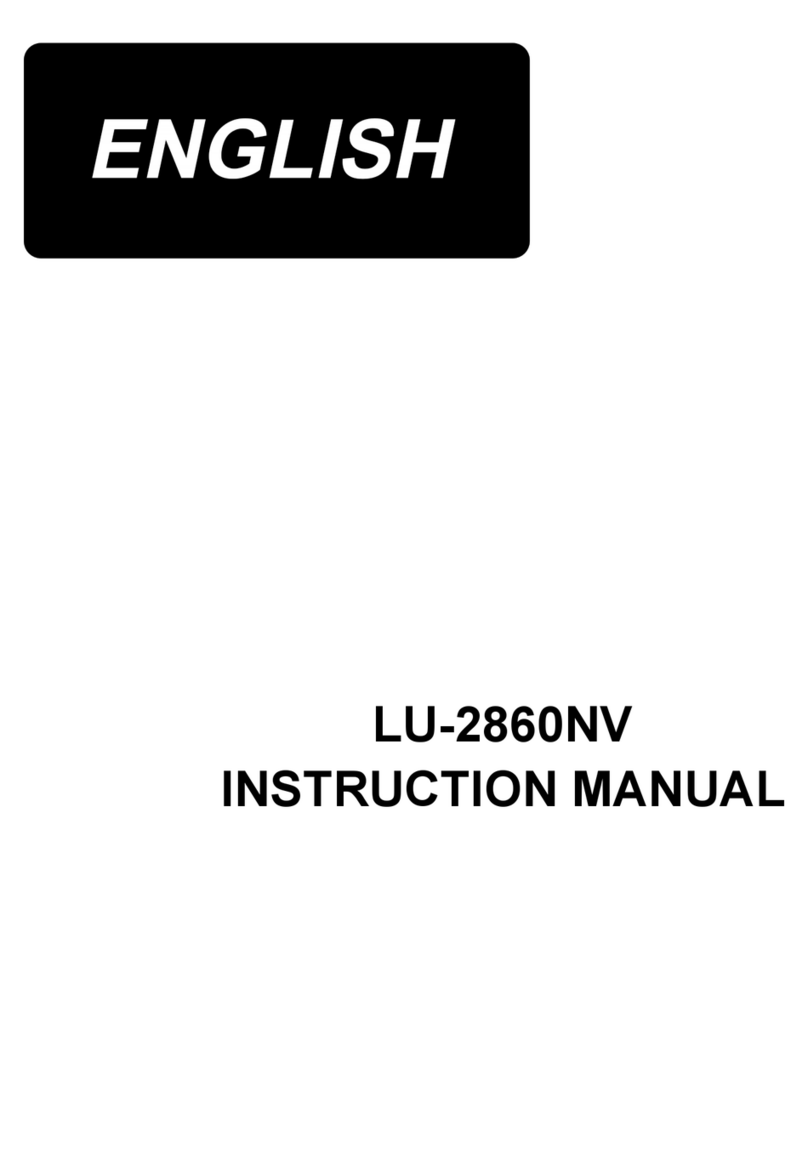

2-2-1. How to carry the sewing machine ............................................................................................3

2-2-2. Caution when placing the sewing machine............................................................................. 3

2-3. Installation............................................................................................................................ 3

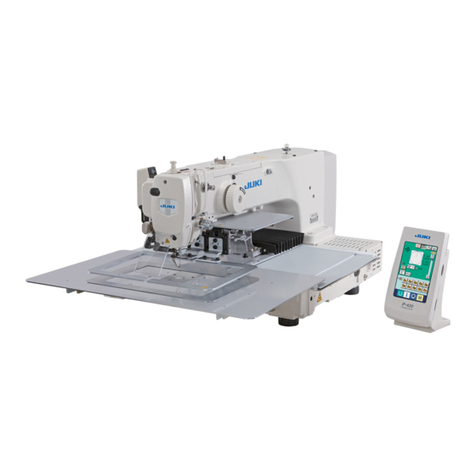

2-4. Installing the pedal sensor ................................................................................................. 4

2-5. Connecting the connector .................................................................................................. 5

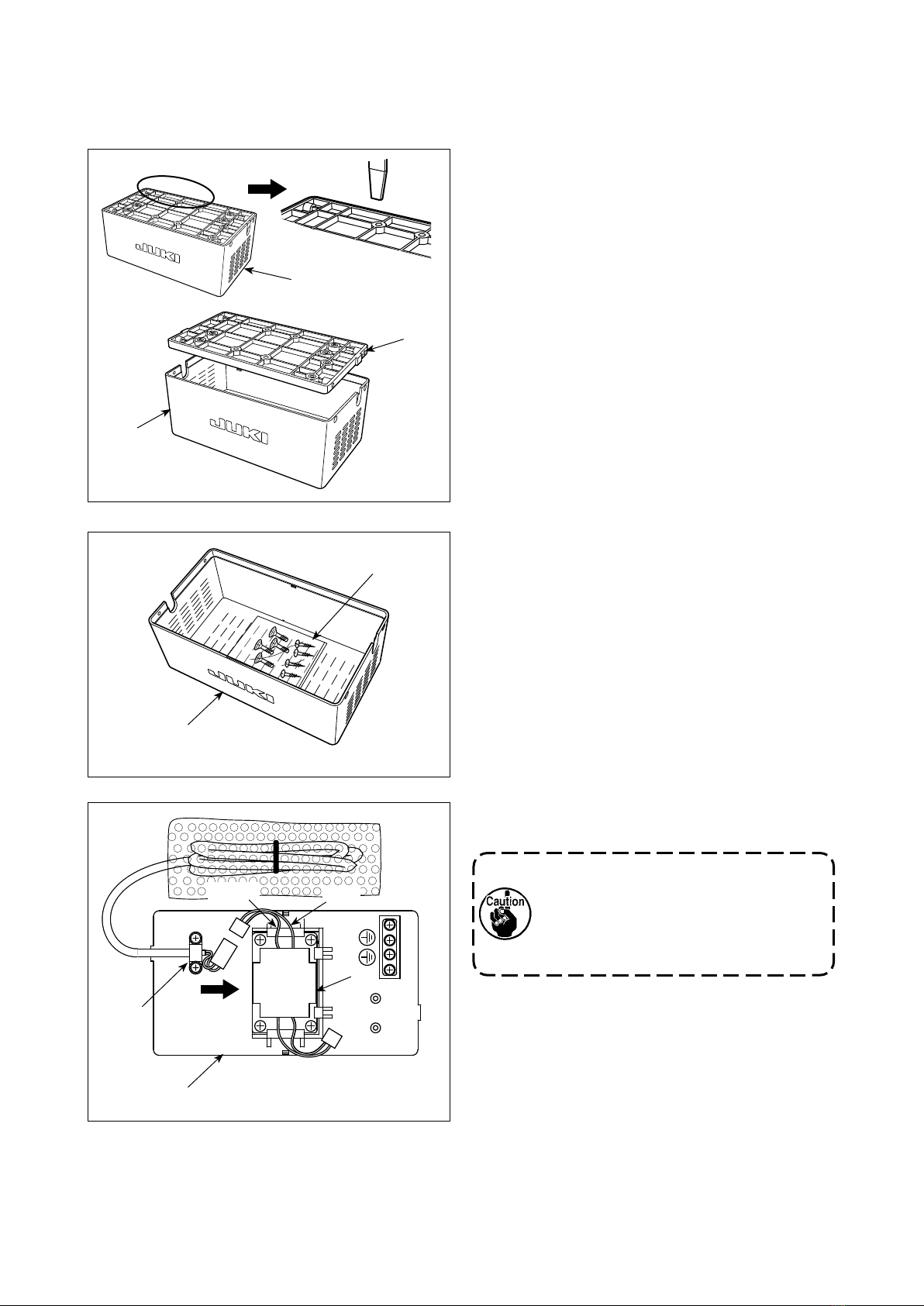

2-6. Installing the reactor box [Only for the EU type models] ................................................ 6

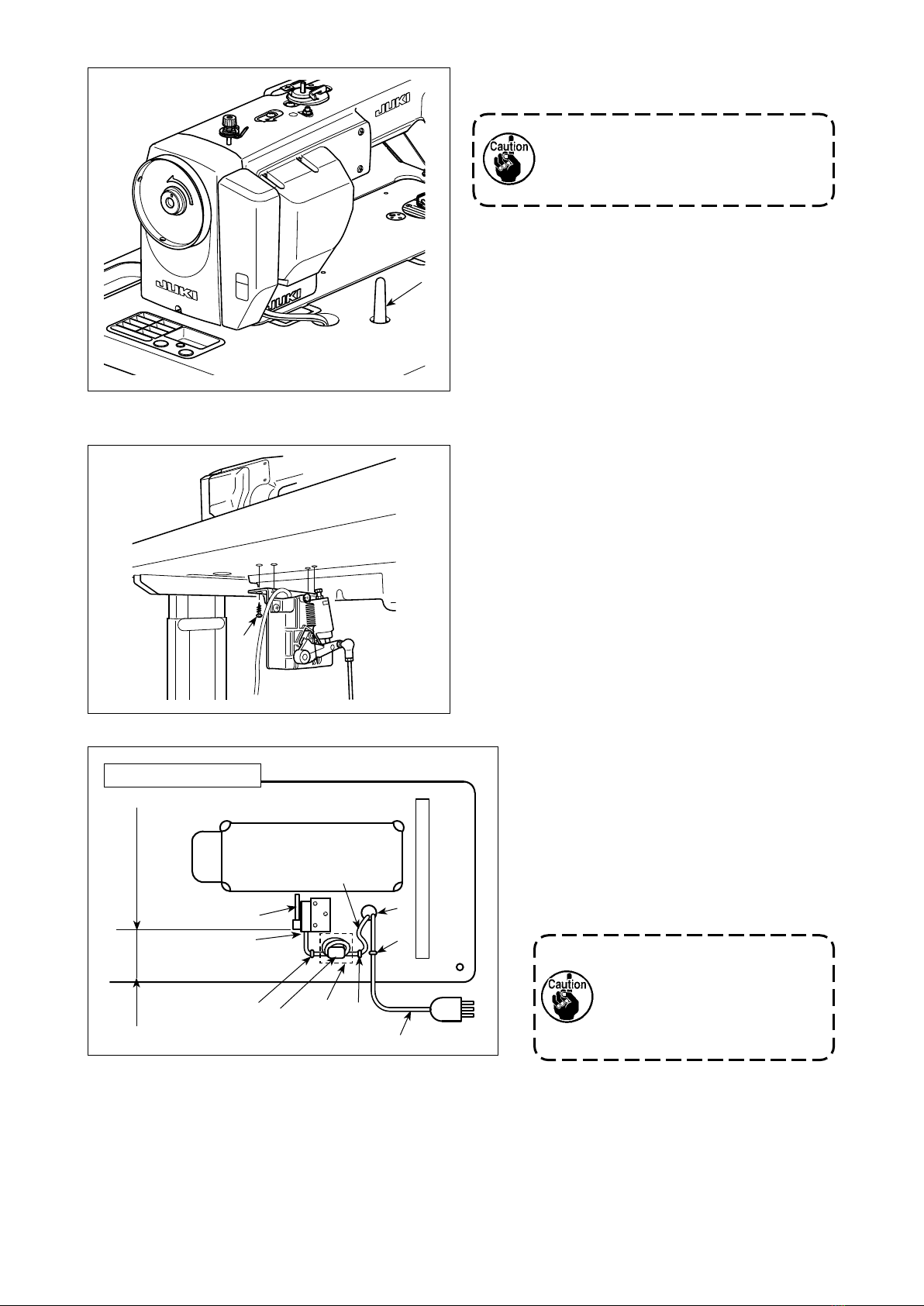

2-7. Installing the power switch................................................................................................. 9

2-7-1. 3-phase 200 to 240V, Single phase 100 to 120V...................................................................... 9

2-8. Installing the thread stand................................................................................................ 11

2-9. Attaching the connecting rod........................................................................................... 11

2-10. Adjustment of the pedal.................................................................................................... 12

2-10-1. Installing the connecting rod................................................................................................ 12

2-10-2. Adjusting the pedal angle ..................................................................................................... 12

2-11. Pedal operation.................................................................................................................. 12

2-12. Power switch...................................................................................................................... 13

2-13. Lubrication ......................................................................................................................... 15

3. PREPARATION BEFORE SEWING .............................................................................. 16

3-1. Attaching the needle ......................................................................................................... 16

3-2. Removing/tting the bobbin case.................................................................................... 16

3-3. Winding the bobbin thread ............................................................................................... 17

3-4. Threading the machine head............................................................................................ 18

3-5. Thread tension................................................................................................................... 18

3-5-1. Adjusting the needle thread tension......................................................................................18

3-5-2. Adjusting the bobbin thread tension ..................................................................................... 18

3-6. Presser foot pressure ....................................................................................................... 19

3-7. Adjusting the stitch length ............................................................................................... 19

3-8. Changing the sewing speed ............................................................................................. 20

3-9. LED hand light ................................................................................................................... 21

3-10. Reverse feed stitching ...................................................................................................... 21

3-11. Adjusting the amount of oil (oil splashes) in the hook .................................................. 22

3-11-1. Adjusting the amount of oil in the hook...............................................................................22

3-11-2. How to conrm the amount of oil (oil splashes)................................................................. 23

3-11-3. Sample showing the appropriate amount of oil.................................................................. 23

3-12. Adjusting the thread take-up spring and the thread take-up stroke............................. 24

4. FOR THE OPERATOR................................................................................................... 25

4-1. How to set the machine head and to initialize data (the factory-set state at the time

of shipment)....................................................................................................................... 25

i