CONTENTS

1. SPECIFICATION ............................................................................................................ 1

2. OUTLINE .......................................................................................................................... 1

(1) Features ........................................................................................................................1

3. NAME OF EACH COMPONENT................................................................................ 2

(1) DDL-9000B/SC-920 ......................................................................................................2

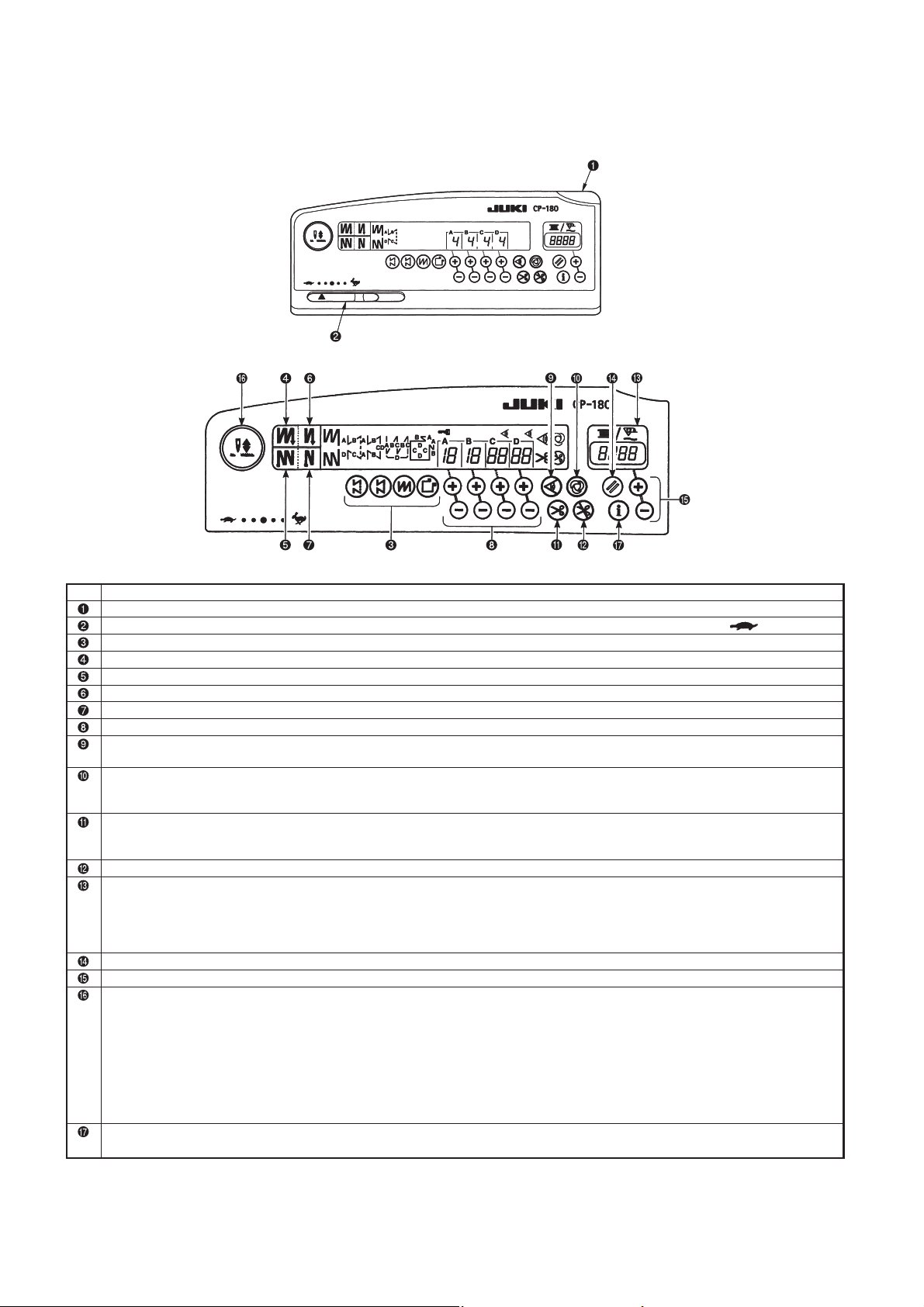

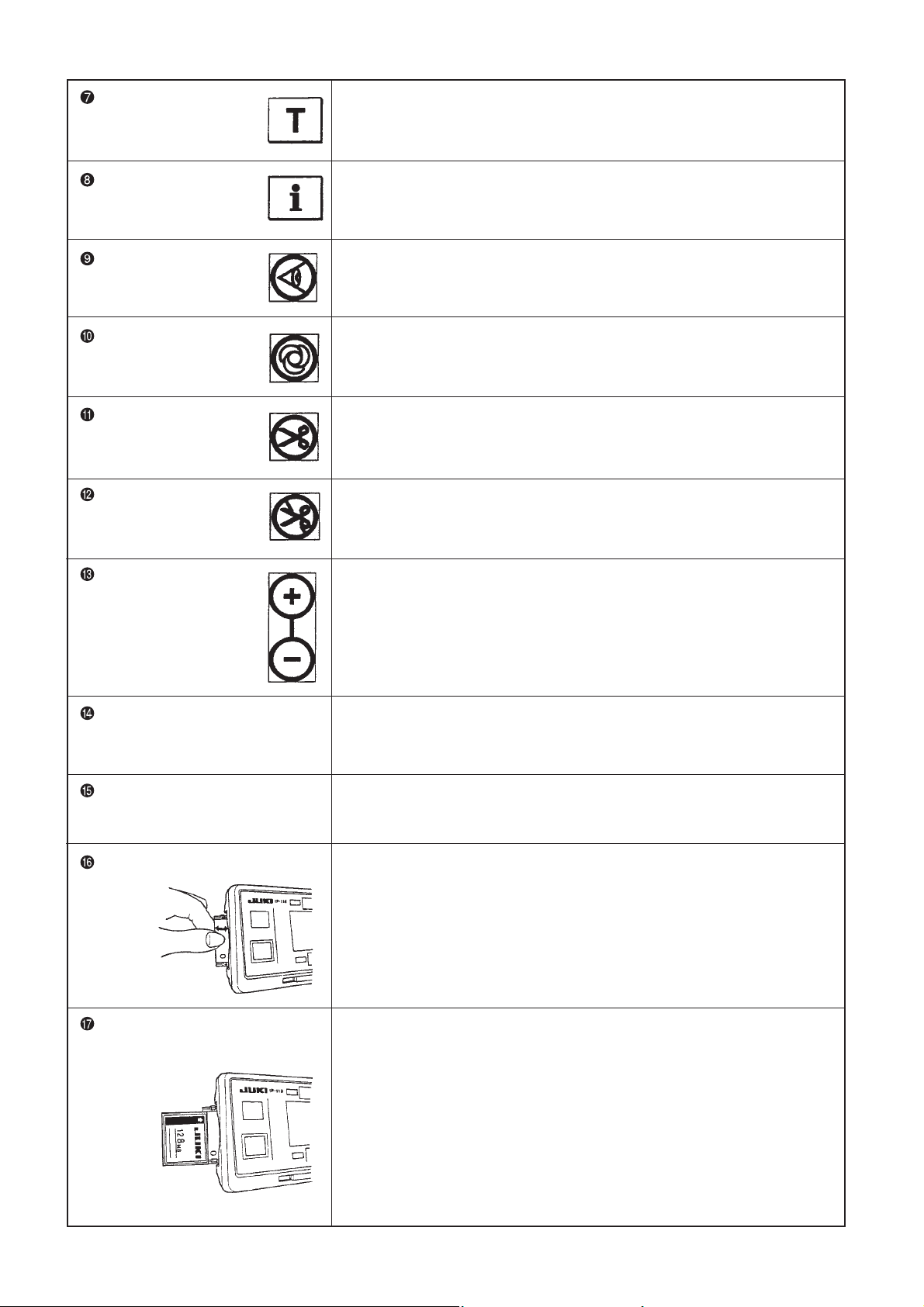

4. EXPLANATION OF OPERATION PANEL .............................................................. 4

(1) List of operation panels of CP-180..............................................................................4

(2) List of operation panel of IP-110F ..............................................................................5

(3) Operation of the connection panel..............................................................................7

1) Connecting procedure of CP-18/180 or IP-110F.................................................................. 7

(4) Explanation of operation panel CP-180 ......................................................................8

(5) Example of application ..............................................................................................12

(6) Explanation of operation panel IP-110F....................................................................15

1) Information.................................................................................................................. 17

2) Error code list (Error display in panel) ............................................................................ 26

3) Warning list ................................................................................................................ 29

5. CONTROL BOX (SC-920).......................................................................................... 30

(1) Connecting the cords ................................................................................................30

(2) Operating procedure ..................................................................................................31

(3) Explanation of the operation panel (CP-18)..............................................................32

(4) Operating procedure of the sewing pattern ............................................................33

(6) Setting for functions ..................................................................................................36

(5) One-touch setting ......................................................................................................35

(7) Setting procedure of the machine head....................................................................37

(8) Machine head list ........................................................................................................38

(9) Adjusting the machine head (Direct-drive motor type sewing machine only)......39

(10) Function setting list..................................................................................................40

(11) Detailed explanation of selection of functions ......................................................44

1) Reverse stitching pattern ................................................................................................ 8

2) Constant-dimension stitching pattern .............................................................................. 9

3) Overlapped stitching pattern ........................................................................................ 10

4) Rectangular stitching pattern ........................................................................................ 11

1) Reverse stitching pattern .............................................................................................. 33

2) Constant-dimension stitching pattern ............................................................................ 34

6. CONNECTING PROCEDURE OF JUKI OPTIONAL DEVICE ........................ 54

(1) Connection of the material end sensor (ED) ............................................................54

(2) Connection of the pedal of standing-work machine (PK) ......................................54

(3) Setting of the auto lifter function ..............................................................................54