Contents

Page

1 Introduction ............................................................................... 5

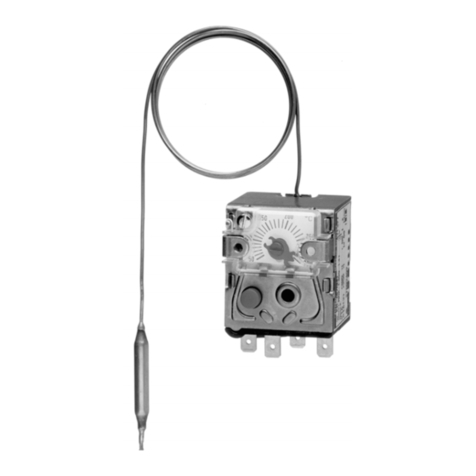

1.1 Typographical conventions ...................................................................... 5

1.1.1 Warning signs ............................................................................................. 5

1.1.2 Note signs ................................................................................................... 5

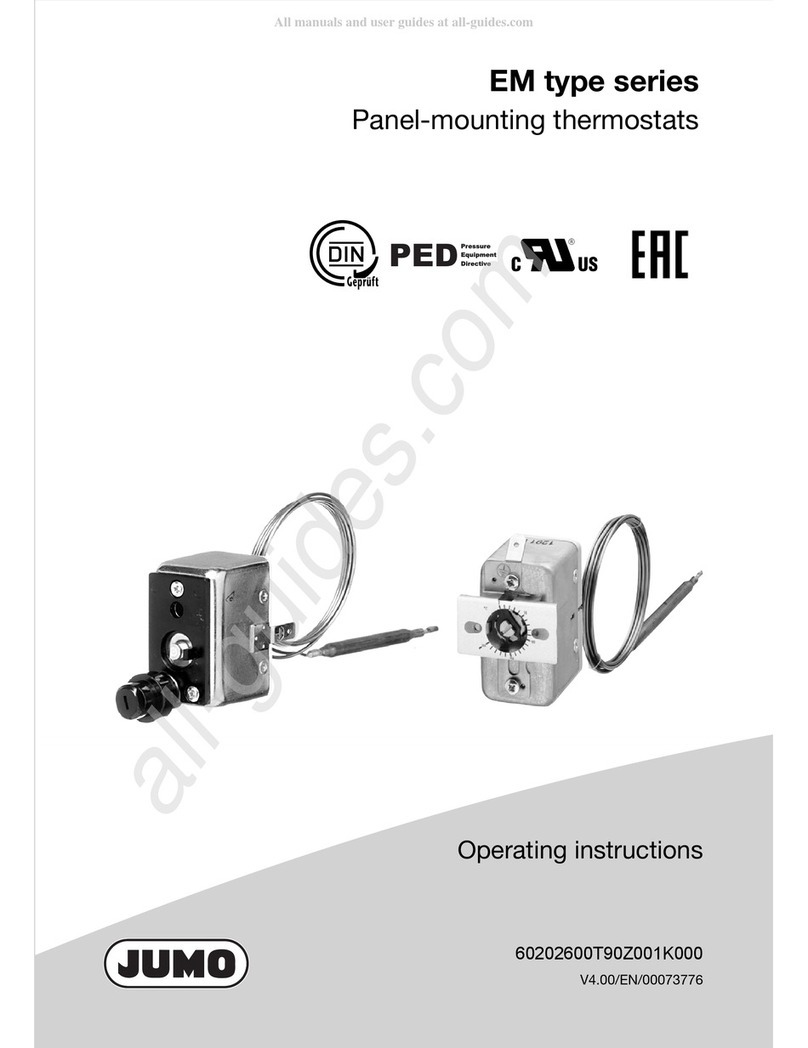

1.2 Application ................................................................................................. 6

1.3 Marking ...................................................................................................... 6

1.4 Safety notes ............................................................................................... 6

2 Instrument identification .......................................................... 7

2.1 Nameplate (example) ................................................................................ 7

2.2 Type designation ....................................................................................... 7

3 Mounting .................................................................................... 8

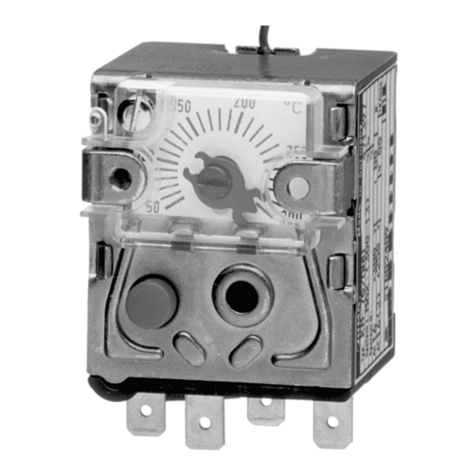

3.1 Dimensions ................................................................................................ 8

3.2 Opening the case .................................................................................... 10

3.3 Fixing the surface-mounting thermostat .............................................. 10

3.3.1 Code s (rigid stem) .................................................................................... 10

3.3.2 Code f (with capillary) ................................................................................ 10

3.4 Capillary / temperature probe / sheath ................................................. 11

3.4.1 General ...................................................................................................... 11

3.4.2 Approved process connections ................................................................ 11

3.5 Permissible pressure at the sheath ....................................................... 12

3.5.1 Sheaths 20 and 30 .................................................................................... 12

3.6 Mounting the probe ................................................................................ 13

4 Installation ............................................................................... 14

4.1 Regulations and notes ............................................................................ 14

4.2 Electrical connection .............................................................................. 15

4.2.1 Closing the case ....................................................................................... 16