Contents

1 Introduction 5

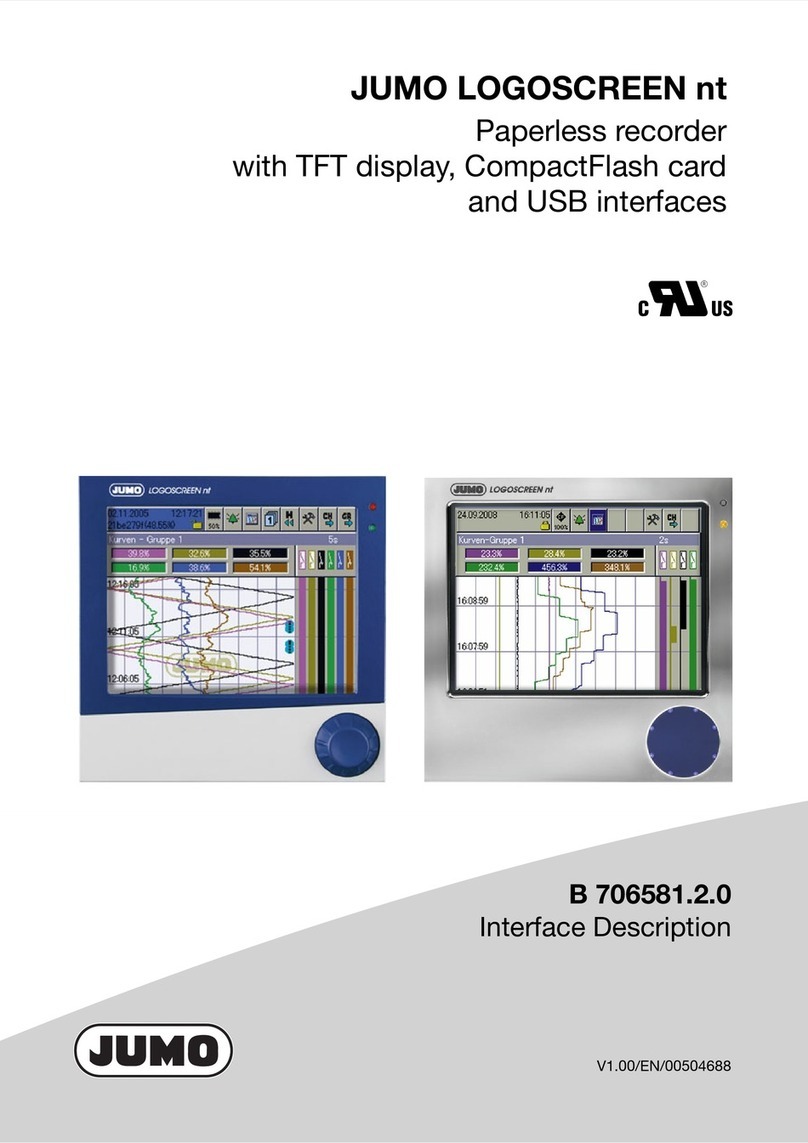

1.1 Preface .......................................................................................................... 5

1.2 Arrangement of the documentation ........................................................... 6

1.2.1 Structure of these Operating Instructions ...................................................... 6

1.3 Typographical conventions ......................................................................... 7

1.3.1 Warning signs ................................................................................................. 7

1.3.2 Note signs ...................................................................................................... 7

1.3.3 Representation ............................................................................................... 8

2 Instrument description 9

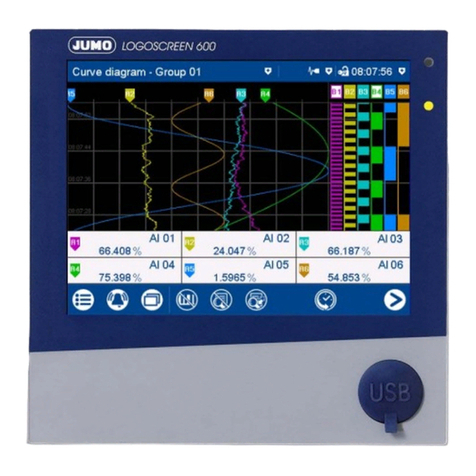

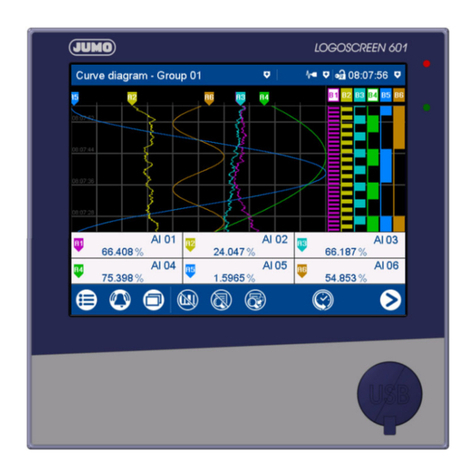

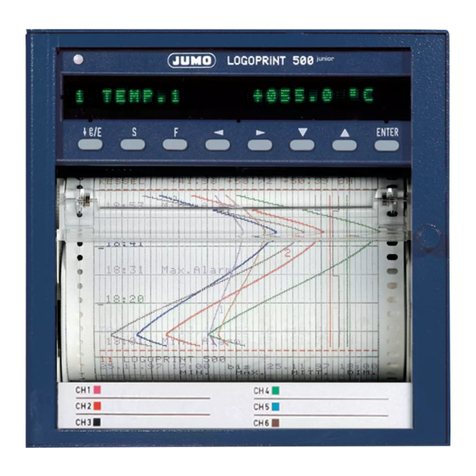

2.1 Display and controls .................................................................................... 9

2.2 Operating principle and graphic elements .............................................. 10

2.3 Analog inputs .............................................................................................. 12

2.4 Event traces ................................................................................................ 13

2.5 Counters / Integrators / Timers ................................................................ 14

2.5.1 Reporting periods of counts ........................................................................ 16

2.5.2 Resetting the counters / integrators / timers ............................................... 16

2.5.3 Behavior on instrument reconfiguration ....................................................... 17

2.6 Math / logic module ................................................................................... 18

2.7 Operating modes ........................................................................................ 21

2.8 Data storage ............................................................................................... 22

3 Operation and visualization 23

3.1 Basic menu ................................................................................................. 24

3.2 Visualization ................................................................................................ 25

3.2.1 Diagram representation with digital display (small measurement) ............... 26

3.2.2 Diagram representation with scaling ............................................................ 27

3.2.3 Diagram representation with bargraph ......................................................... 27

3.2.4 Large digital display (large measurement) .................................................... 28

3.2.5 Curve representation (header switched off) ................................................. 28

3.2.6 Evaluating the stored measurement data .................................................... 29

3.2.7 Counters / integrators / operating time ........................................................ 32

3.3 Parameter setting ....................................................................................... 33

3.4 Configuration .............................................................................................. 35