Contents

1 About this Manual

1.1 Preface ...................................................................................................................... 3

1.2 Arrangement of the documentation ......................................................................... 4

1.3 Typographical conventions ...................................................................................... 5

1.3.1 Warnings ................................................................................................................... 5

1.3.2 Notes ........................................................................................................................ 5

1.3.3 Presentation .............................................................................................................. 6

2 Identifying the instrument version

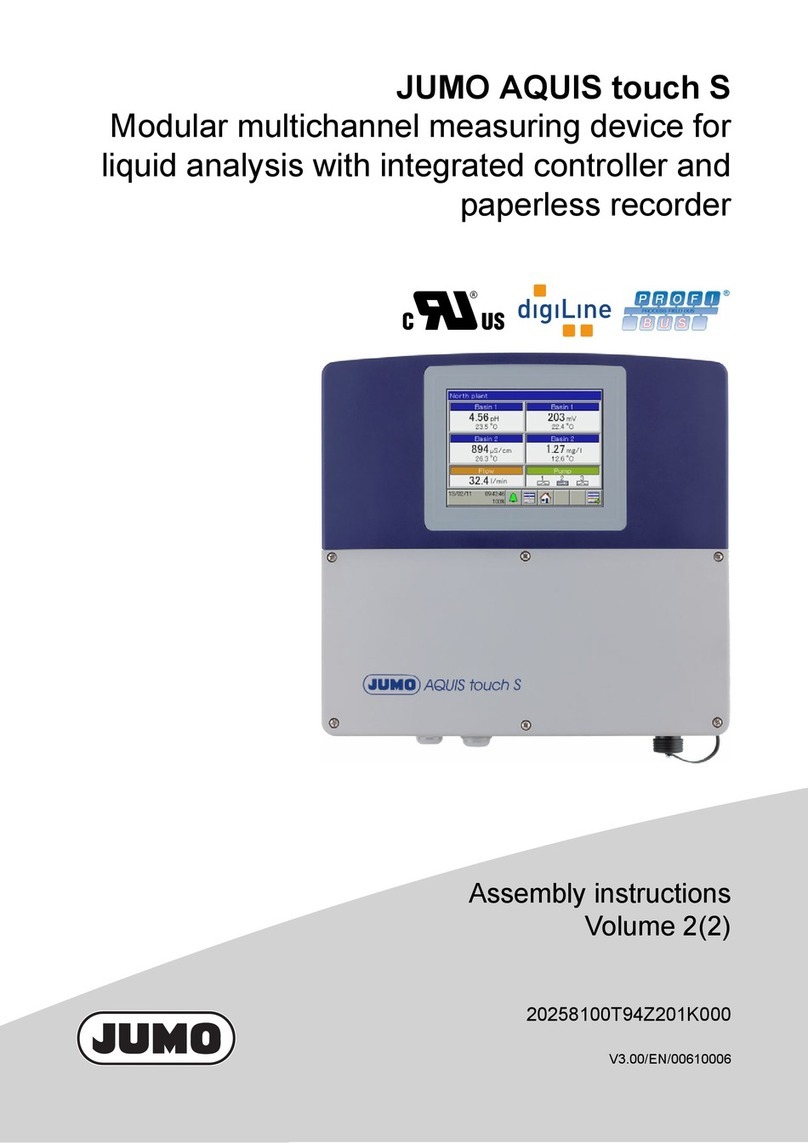

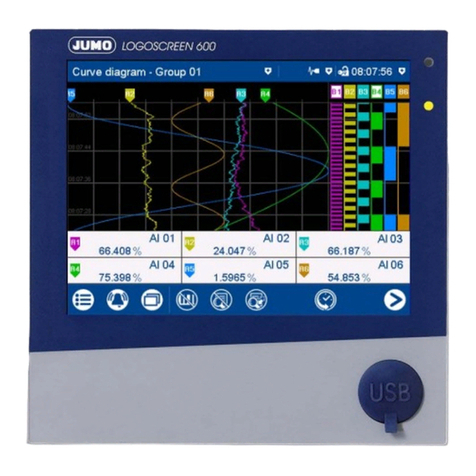

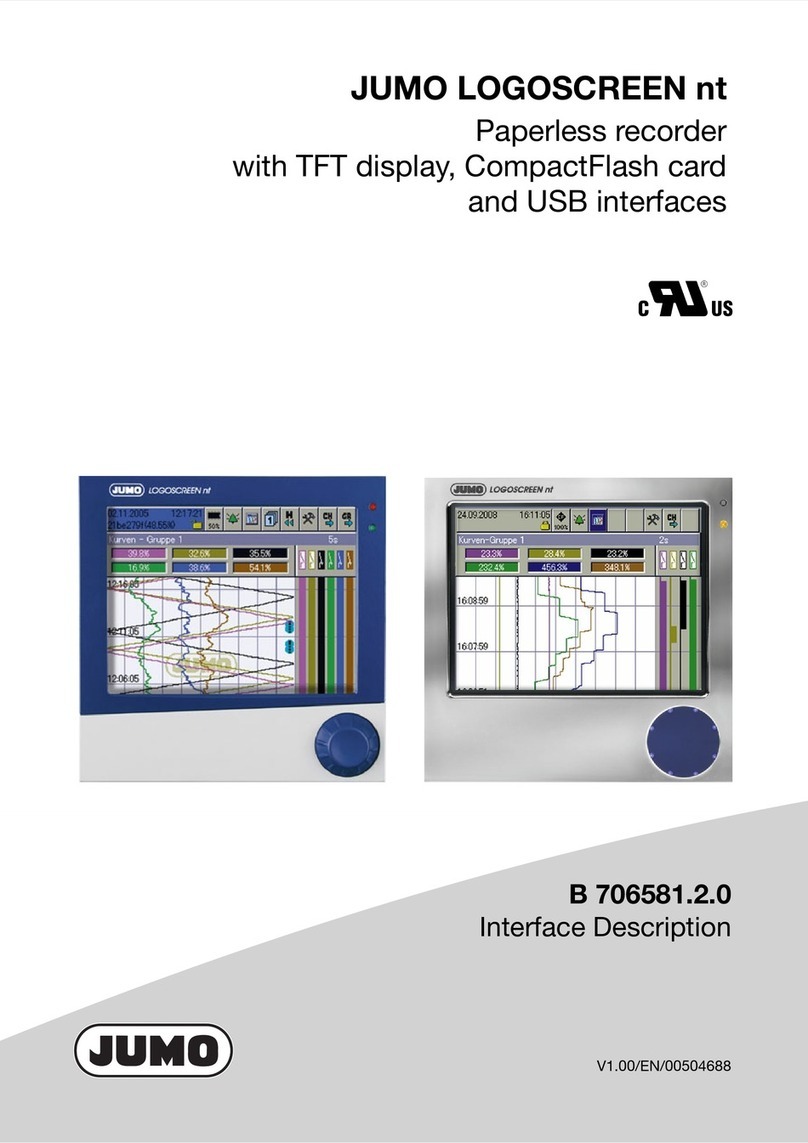

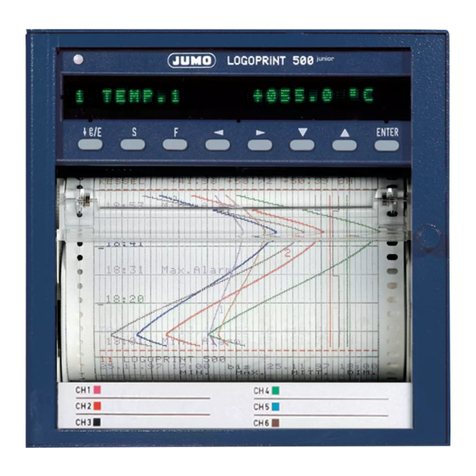

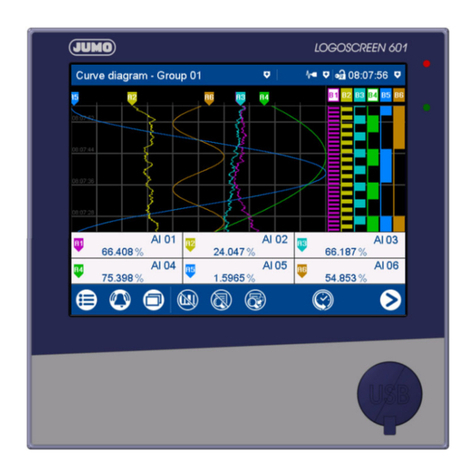

2.1 Instrument description .............................................................................................. 7

2.2 Type designation ...................................................................................................... 8

3 Installation

3.1 Location and climatic conditions ........................................................................... 11

3.2 Fitting in position .................................................................................................... 12

4 Electrical connection

4.1 Notes on installation ............................................................................................... 13

4.2 Connection diagram ............................................................................................... 14

5 Startingup

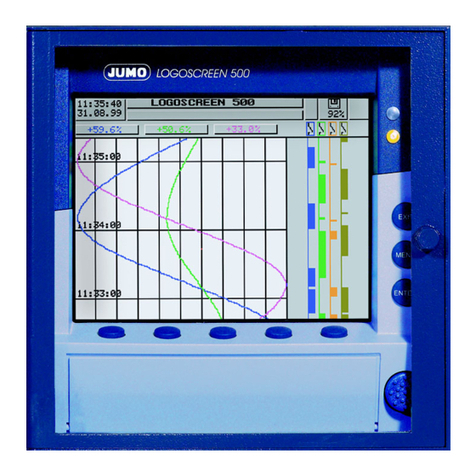

5.1 Display and controls ............................................................................................... 15

5.2 Opening and closing the door ............................................................................... 15

5.3 Marking the channel label ...................................................................................... 15

5.4 Fitting the fibre pens ............................................................................................... 16

6 Preparation

6.1 Operating modes and status .................................................................................. 17

6.2 Operating principle ................................................................................................. 18

7 Text printing

7.1 Printing priorities ..................................................................................................... 23

7.2 Time ........................................................................................................................ 24

7.3 Change of chart speed ........................................................................................... 25

7.4 Recording start and end ......................................................................................... 26

7.5 Print test .................................................................................................................. 27

7.6 Service print ............................................................................................................ 28