Inhalt

10 Configuration .....................................................................9

10.1 General .............................................................................................. 9

10.2 Important information ......................................................................... 9

10.3 Basic settings ................................................................................... 10

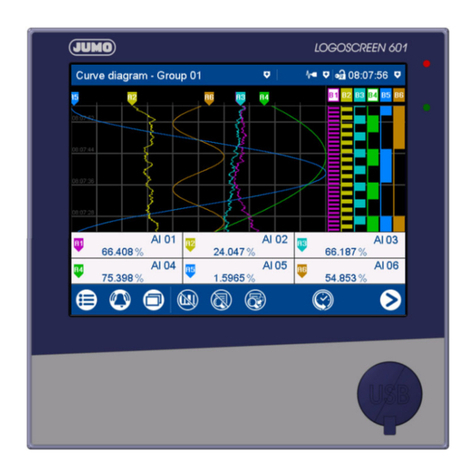

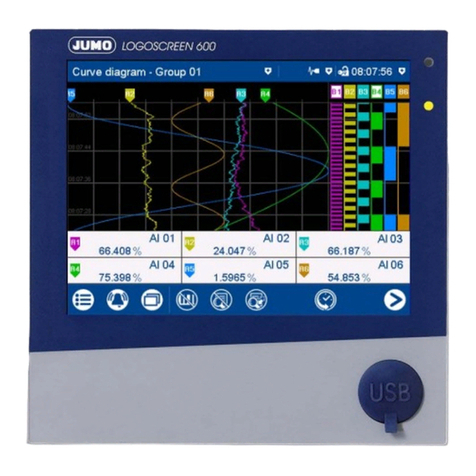

10.4 Display .............................................................................................11

10.4.1 General ............................................................................................ 11

10.4.2 Screen ............................................................................................. 12

10.4.3 Colors .............................................................................................. 12

10.5 Operating loop ................................................................................. 13

10.5.1 General screens .............................................................................. 13

10.5.2 Detailed screens .............................................................................. 14

10.6 Analog inputs ................................................................................... 15

10.6.1 Base unit temperature inputs ........................................................... 15

10.6.2 Universal inputs of base unit and optional boards ........................... 17

10.6.3 Calibration timer ............................................................................... 19

10.6.4 pH/Redox/NH3analysis inputs ......................................................... 21

10.6.5 Calibration timer ............................................................................... 22

10.6.6 CR/Ci analysis inputs (conductive/inductive conductivity) ............... 23

10.6.7 Calibration timer ............................................................................... 24

10.6.8 CR/Ci measuring ranges ................................................................. 24

10.7 Analog outputs of base unit and optional boards ............................. 28

10.8 Digital inputs of base unit and optional boards ................................ 29

10.9 Digital outputs of base unit and optional boards .............................. 30

10.10 Digital sensors ................................................................................. 31

10.10.1 General ............................................................................................ 31

10.10.2 Configuration ................................................................................... 32

10.10.3 Sensor alarms .................................................................................. 38

10.10.4 CIP/SIP definition (JUMO digiLine pH only) .................................... 41

10.10.5 Calibration timer ............................................................................... 41

10.11 Input alarm functions ....................................................................... 42

10.11.1 Alarms for analog signals and digital sensors ................................. 42

10.11.2 Digital signal alarms ......................................................................... 45