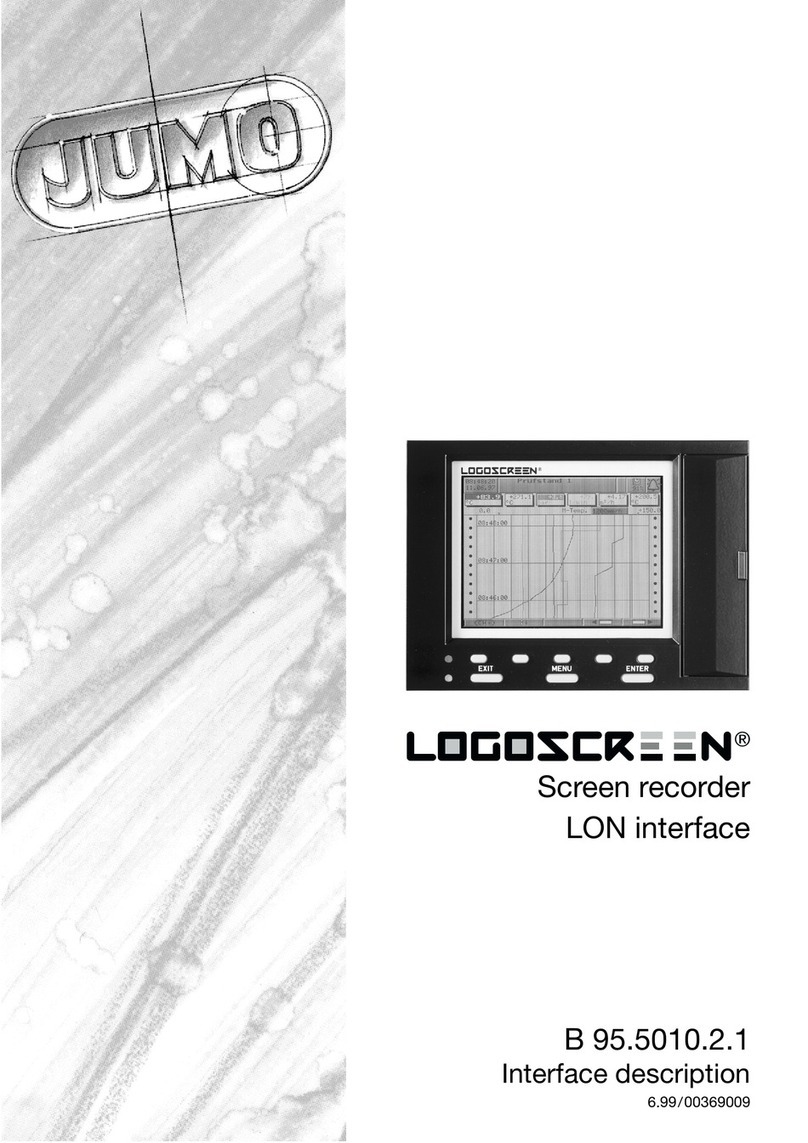

2 Identifying the instrument version

10

2.2 Type designation

Paperless recorder for secure acquisition of FDA-compliant meas. data

(1) Basic version

955011/00 paperless recorder, no analog inputs

955011/01 paperless recorder, no analog inputs, incl. PC

software package and interface cable/adapter

955011/10 paperless recorder with 6 analog inputs

955011/20 paperless recorder with 6 analog inputs, incl. PC

software package and interface cable/adapter

955011/11 paperless recorder with 12 analog inputs

955011/21 paperless recorder with 12 analog inputs incl. PC

software package and interface cable/adapter

(2) Inputs 1 — 6 (configurable)

x x 000 not assigned

x x x x 888 factory-set

(3) Inputs 7 — 12 (configurable)

x x x x 000 not assigned

x x 888 factory-set

(4) Interface

x x x x x x 51 RS232C (standard)

x x x x x x 54 RS422/485

x x x x x x 66 RS232C and LON

x x x x x x 67 RS422/485 and LON

x x x x x x 68 RS232C and PROFIBUS-DP

x x x x x x 69 RS422/485 and PROFIBUS-DP

(5) Internal memory

x x x x x x 0032 32MB backup memory

x x x x x x 0064 64MB backup memory

x x x x x x 0128 128MB backup memory

(6) External memory

x x x x x x 0000 no external memory

x x x x x x 0032 32MB CompactFlash memory card

x x x x x x 0064 64MB CompactFlash memory card

x x x x x x 0128 128MB CompactFlash memory card

(7) Supply

x x x x x x 23 110 — 240V AC +10/-15%, 48 — 63Hz

xxxxxx 25 20—30VAC/DC,48—63Hz

(8) Extra codes

x x x x x x 008 Ethernet connection

x x x x x x 020 lithium battery for memory buffering (ex-factory)

xxxxxx 021 storage capacitor (instead of extra code 020)

x x x x x x 061 UL approval

x x x x x x 258 7 logic inputs, 1 open-collector output,

4 relay outputs, voltage output 24V DC 50mA

xxxxxx 350 universal carrying case TG-352

x x x x x x 444 stainless steel front with membrane keys

(1) (2) (3) (4) (5) (6) (7) (8)

Order code - , - - - - / ,...

Order example 955011/10 - 888 , 000 - 51 - 0032 - 0032 - 23 / 0201

1. List extra codes in sequence, separated by commas.

2. The UL approval (061) only applies to the panel-mounting unit.