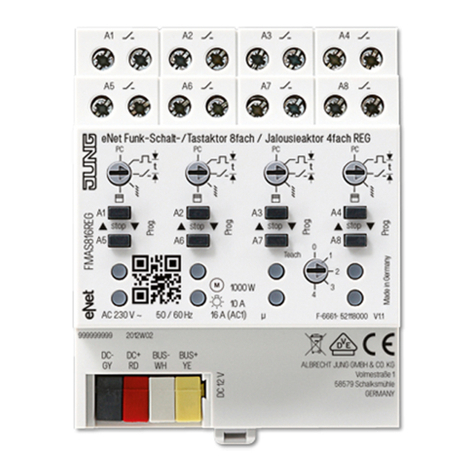

LB management

KNX RF push-button

3 Function

System information

This device is a product of the KNX system and complies with the KNX directives. Detailed tech-

nical knowledge obtained in KNX training courses is a prerequisite to proper understanding.

The function of this device depends upon the software. Detailed information on loadable soft-

ware and attainable functionality as well as the software itself can be obtained from the manu-

facturer´s product database.

The device can be updated. Firmware can be easily updated with the Jung ETS Service App

(additional software).

The device is KNX Data Secure capable. KNX Data Secure offers protection against manipula-

tion in building automation and can be configured in the ETS project. Detailed specialist know-

ledge is required. A device certificate, which is attached to the device, is required for safe com-

missioning. During mounting, the certificate must be removed from the device and stored se-

curely.

The range of a radio system depends on various external circumstances. The range can be op-

timised by the choice of installation location. The product documentation for this device contains

application basics for the KNX radio system.

Planning, installation and commissioning of the device are carried out with the aid of the ETS,

version 5.7.5 and above.

Intended use

– Operation of loads, e.g. light on/off, dimming of brightness and colour temperature, Vene-

tian blinds up/down, value transmitter 1 byte, 2 bytes, 3 bytes and 6 bytes, brightness val-

ues, temperatures, calling up and saving of light scenes

– Room temperature control

– Operation in cabled KNX systems via radio media coupler (see chapter Accessories)

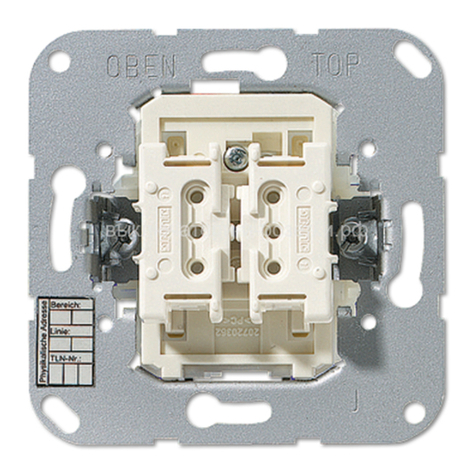

– Operation of switching, dimming, DALI, Venetian blind or room temperature insert or 3-

wire extension from the LB-Management

Product characteristics

– Activation of blind/shutters, with Venetian blind insert

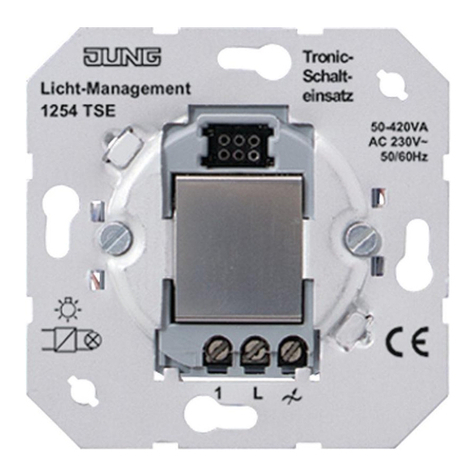

– Switching and dimming of lighting, with switching or dimming insert

– Colour temperature control of lighting, with DALI insert TW

– Room temperature control, with RTC insert

– Control via the extension terminal on the LB insert (installation push-button, extension 2-

wire, extension 3-wire)

– Push-button sensor functions switching, dimming, Venetian blind, value transmitter, scene

extension, 2-channel operation and controller extension adjustable

– Operating concept (rocker or button) adjustable for every operating area

– Button assessment (single-area operation or dual-area operation) adjustable

– One or two functions per operating area

– Controller extension with adjustable operating mode selection, forced operating mode

switch over, presence function and setpoint shift

– Status LED – optionally red, green, blue – adjustable per rocker

– LED functions orientation lighting and night reduction can be set separately

– Brightness of LED adjustable and switchable while in operation

– Disable or function switch-over of all or of individual button functions possible with dis-

abling function

– Temperature measurements optionally with device internal sensor and external sensor

connected via communication object (only with suitable inserts)

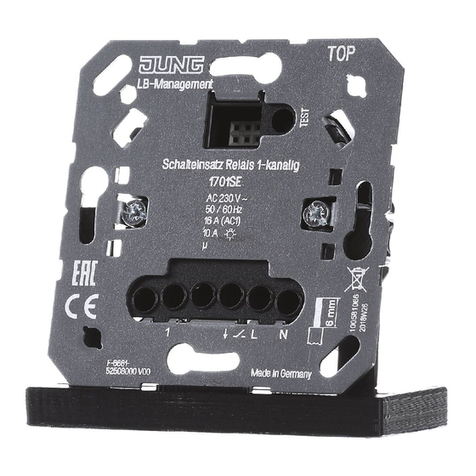

Temperature measurements are only possible in combination with the following inserts:

- Relay switch insert 1-channel

3 / 12

32403803 03.11.2021

J0082403803