KD-S6250/KD-S580

1-10

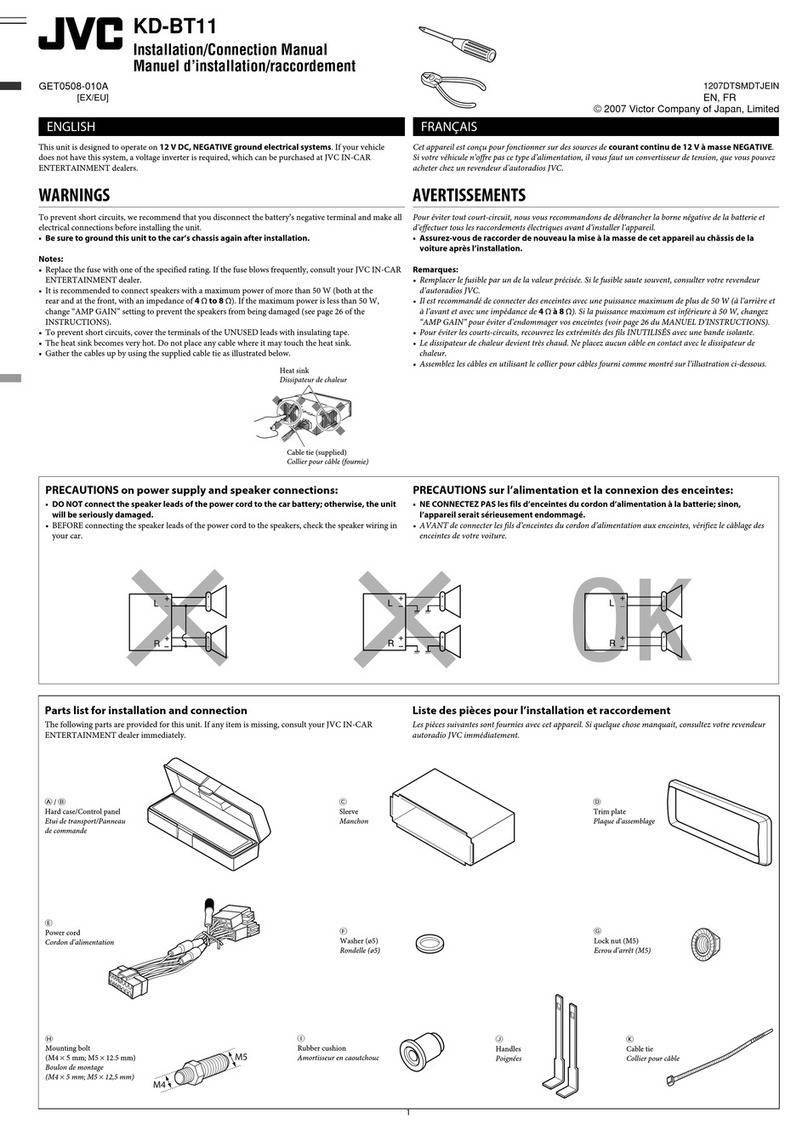

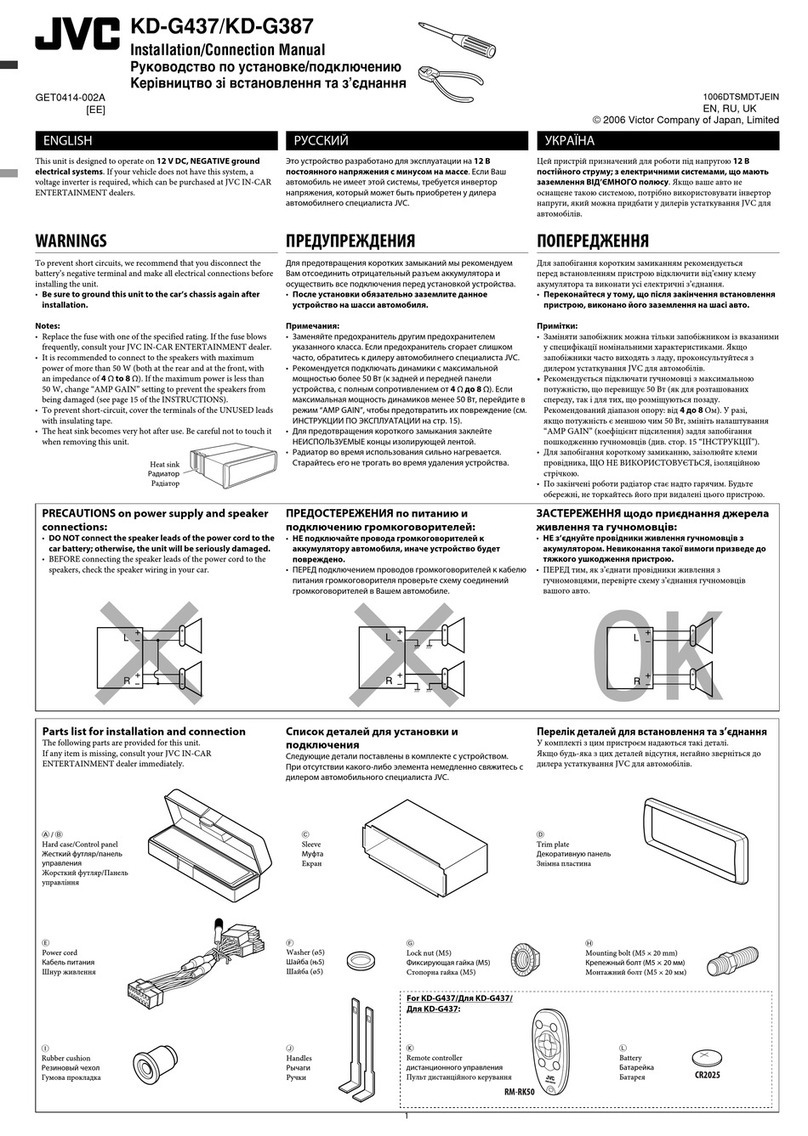

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism ass’y.

Remove the two screws K and the feed motor ass’y.

1.

Removing the feed motor ass’y

(See Fig.10)

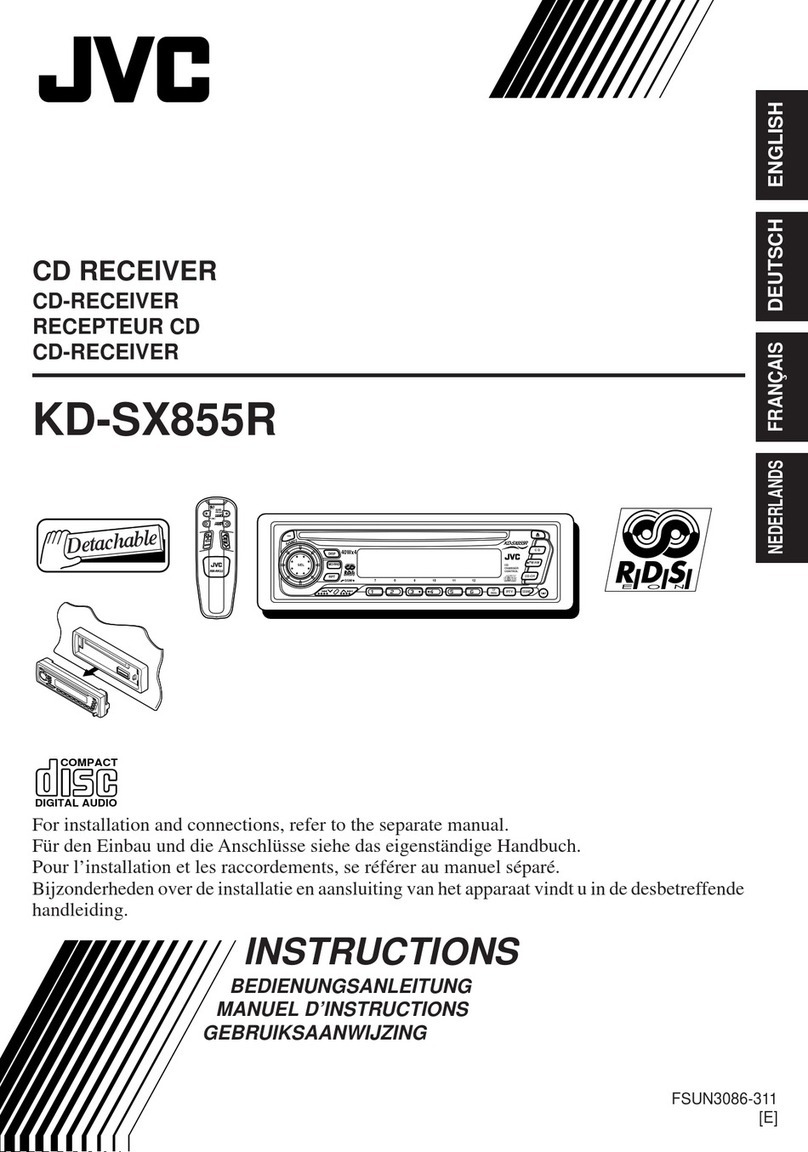

*Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism ass’y and the

feed motor ass’y.

Detach the FD gear part of the pickup unit upward.

Then remove the pickup unit while pulling out the

part n of the FD screw.

1.

Remove the screw L attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

2.

Removing the pickup unit

(See Fig.10 and 11)

When reattaching the pickuap unit,

reattach the part o of the pickup unit,

then the part n of the FD screw.

ATTENTION:

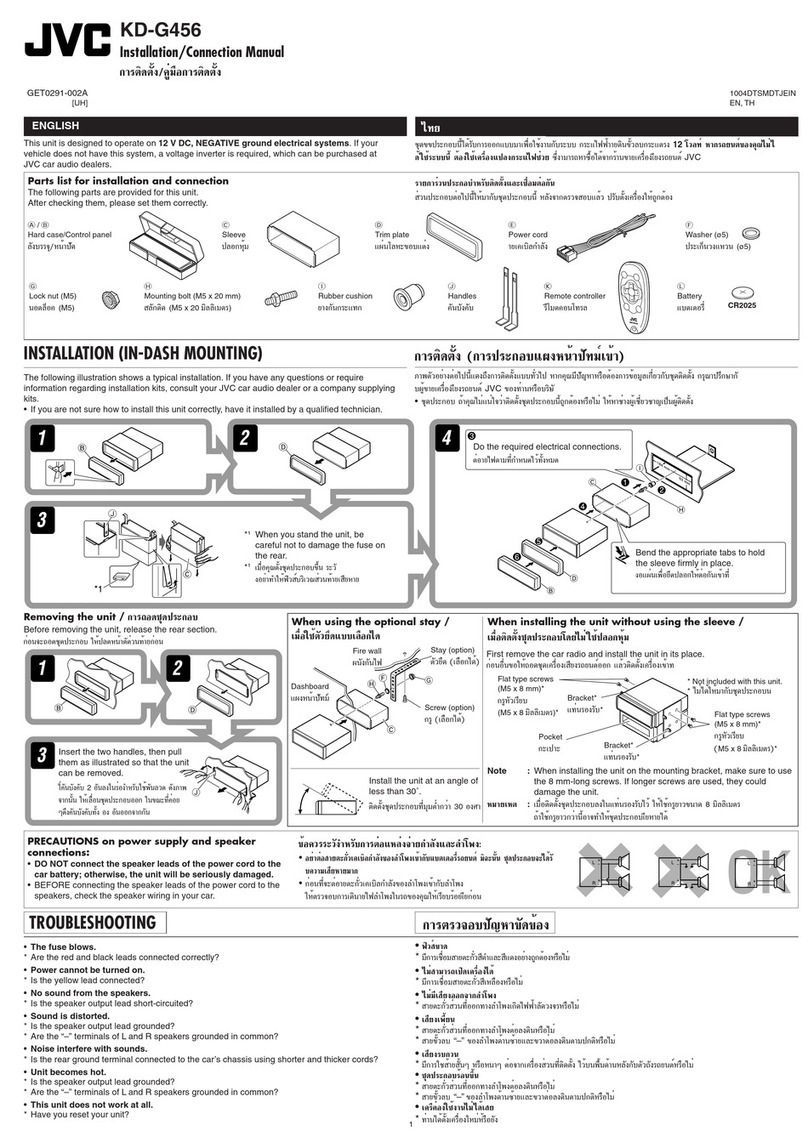

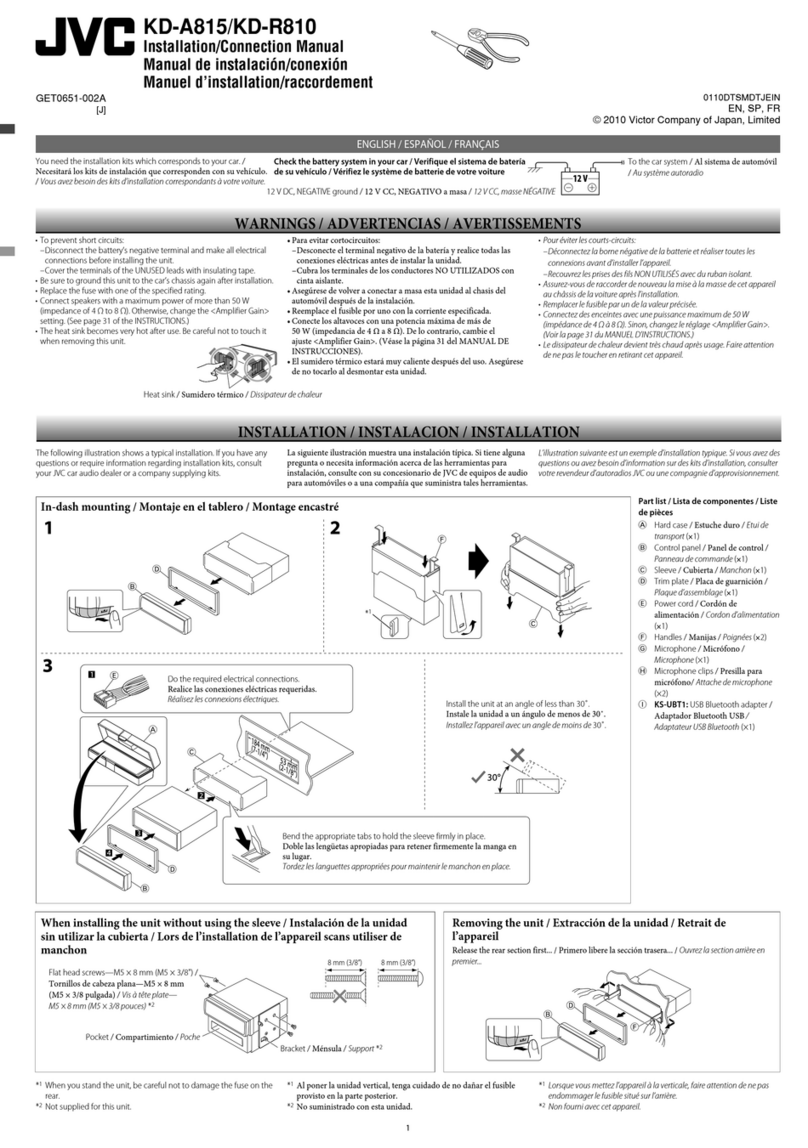

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism ass’y and the

feed motor ass’y.

Turn up the CD mechanism ass’y and remove the

two springs p on both sides of the clamper arms.

Open the clamper arm upward.

Turn the turn table, and remove the two screws M

and the spindle motor.

1.

2.

Removing the spindle motor

(See Fig.12 and 13)

Fig.10

Fig.11

Fig.12

Fig.13

Spindle motor

pp

Pickup unit

Part n

FD screw

Feed motor ass’y

FD gear Pickup unit

Part O

K

Nut push spring plate

Pickup mount nut

Pickup unit

FD screw

L

M

M