KS-FX915R/KS-FX815

1-7

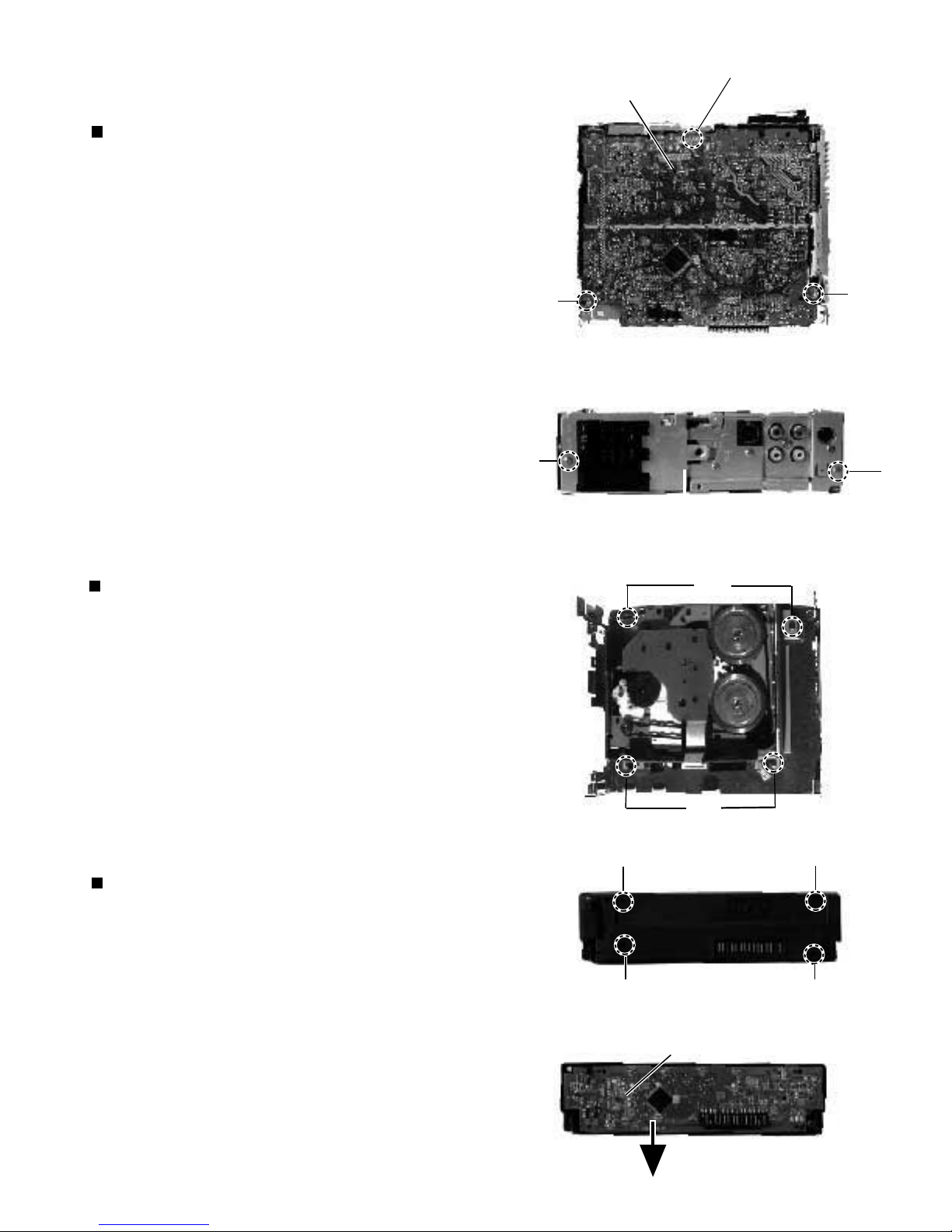

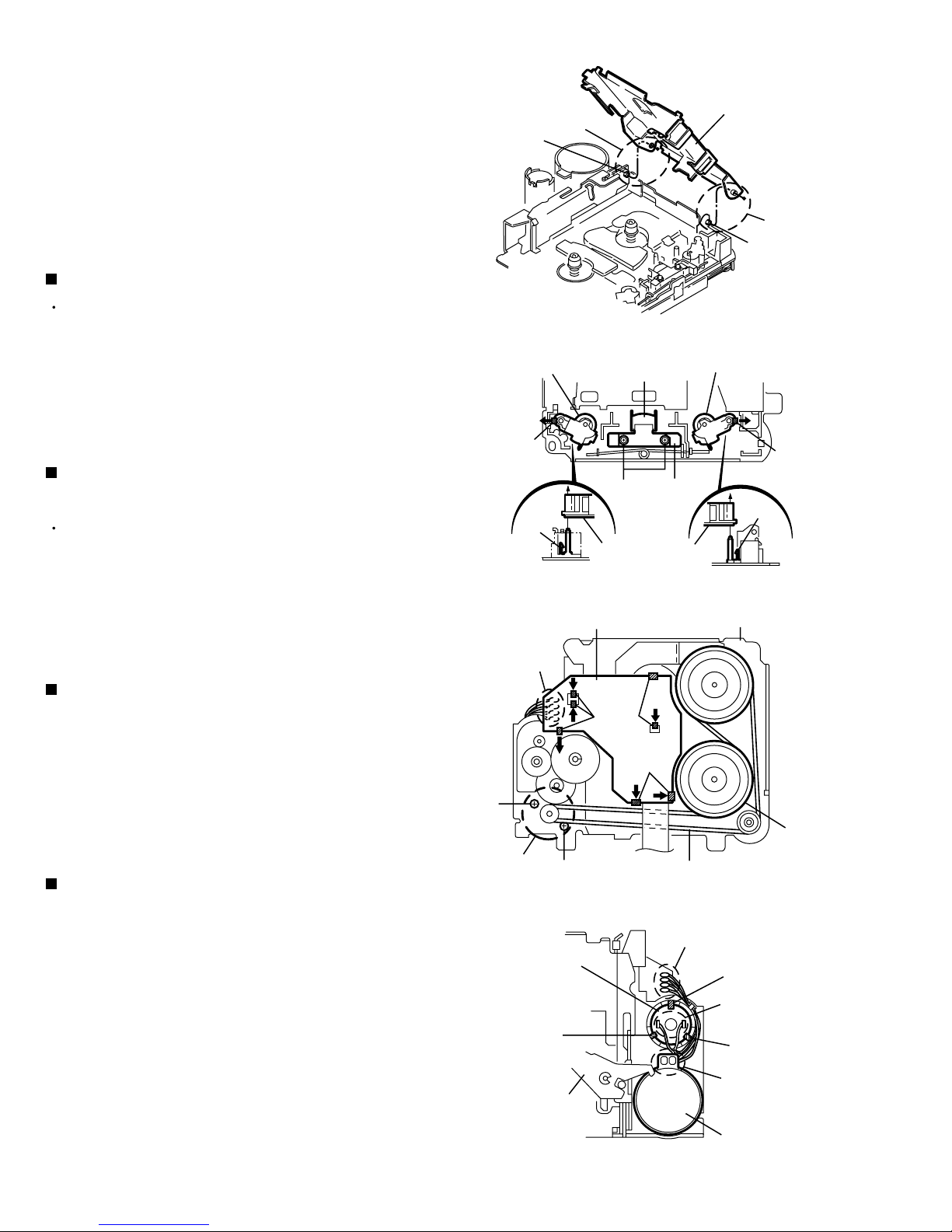

Unsolder the soldering bon the head relay board.

Remove the screw Cattaching the head relay board.

Remove the head relay board in the direction of the

arrow while releasing the two joints c.

1.

2.

3.

Removing the head relay board

(See Fig.4)

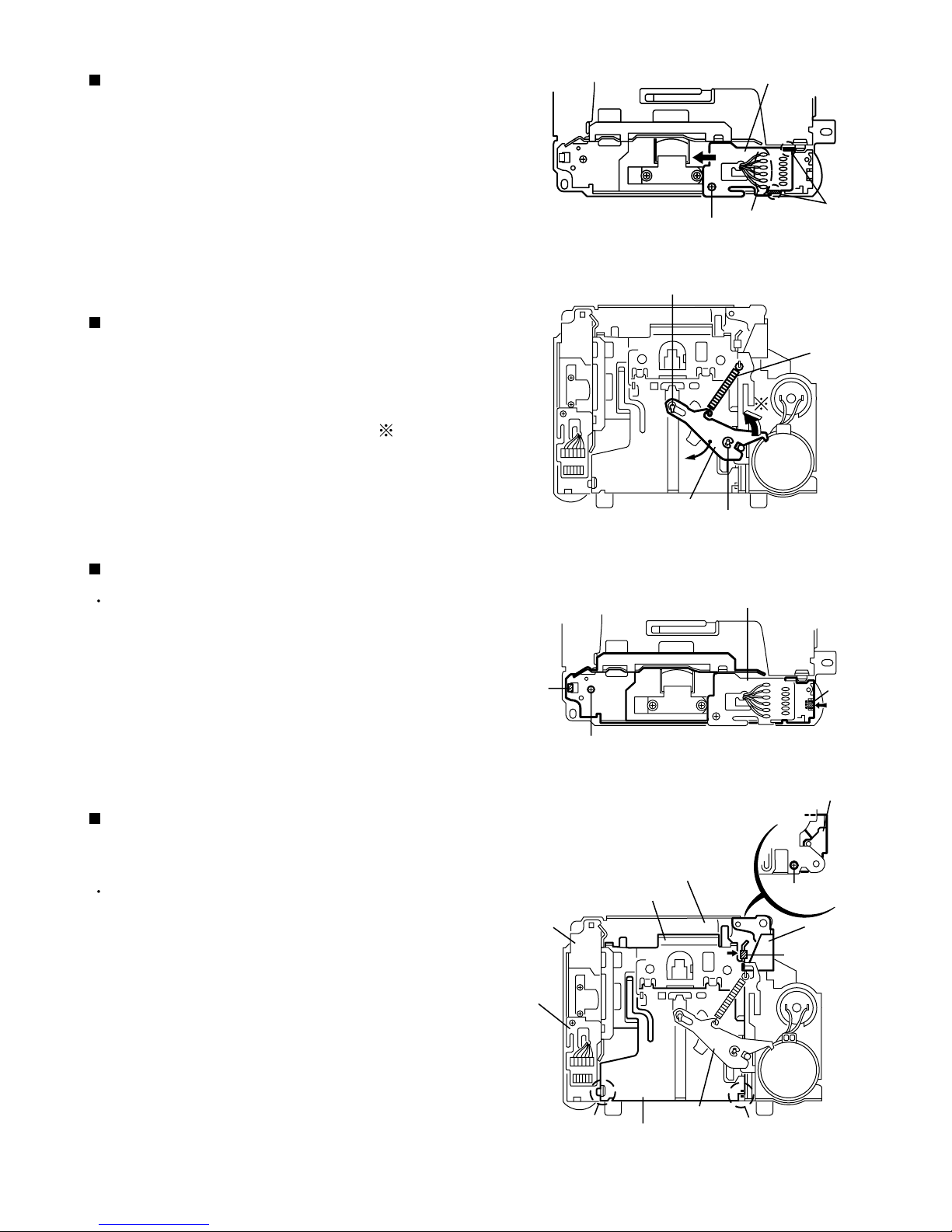

Remove the E washer attaching the load arm using

a pincette or something like that and remove the

spring d.

Move the part of the load arm marked upwards to

release it from the axis of rotation. Then rotate the

load arm in the direction of the arrow to remove it

from the cach.

1.

2.

Removing the load arm (See Fig.5)

Prior to performing the following procedure, remove

the head relay board.

Remove the screw Dattaching the sub chassis.

Push the tab ein the direction of the arrow to detach

the one side of the sub chassis. Then release the

sub chassis from the tab f.

1.

2.

Removing the sub chassis (See Fig.6)

Prior to performing the following procedure, remove

the head relay board, the load arm and the sub

chassis.

Remove the screw Eattaching the reinforce bracket.

Remove the reinforce bracket.

Push the tab gfixing the cassette holder in the

direction of the arrow and open the cassette holder

and the holder arm upward until they stop at an

angle of 45 degrees. Move the two joints hto the

side and remove the cassette holder and the holder

arm from the shaft.

1.

2.

3.

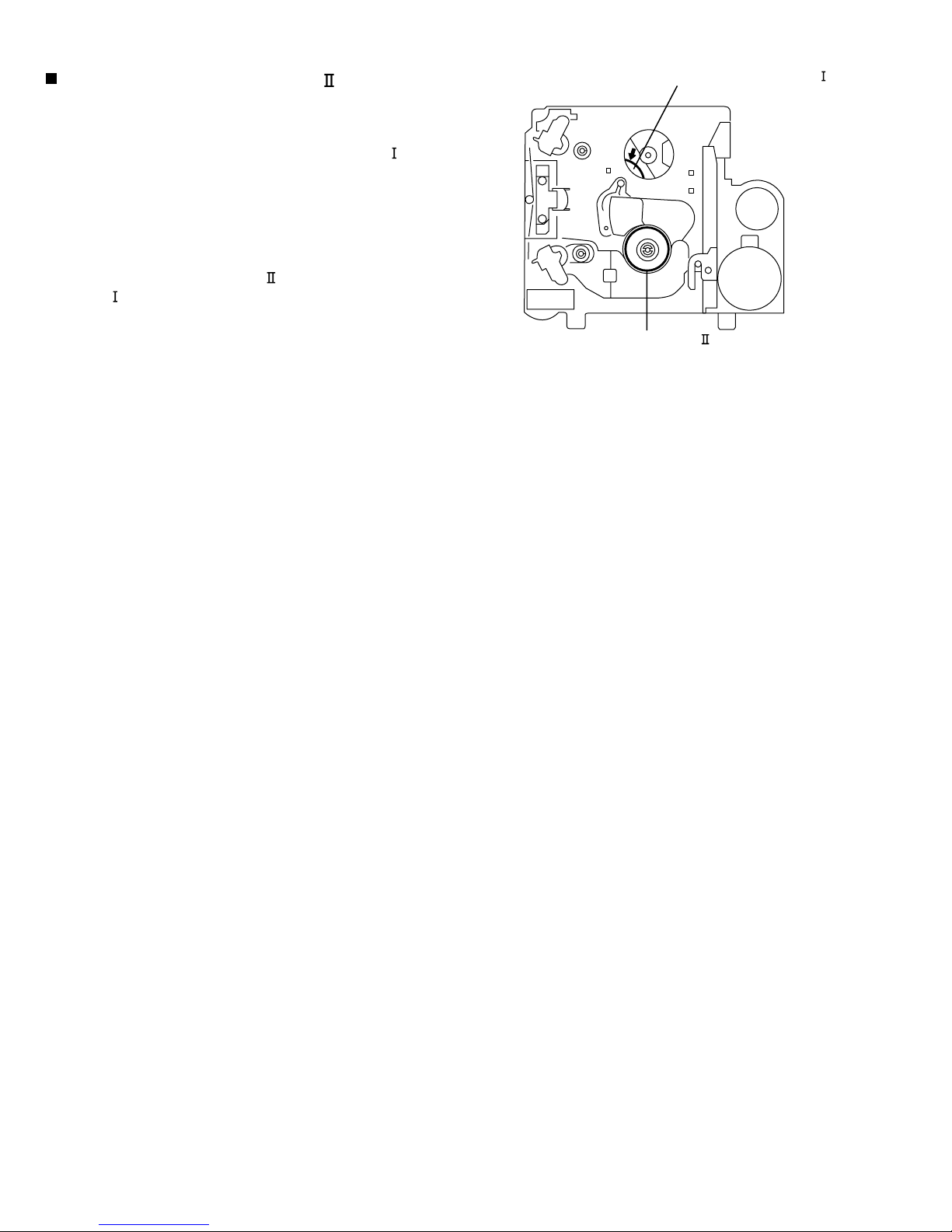

Removing the cassette holder and the

holder arm in the eject mode

(See Fig.7 and 8)

Fig.4 CSoldering b Joint c

Fig.6

Tab f

D

Tab e

Cach

Head relay board

Head relay board

Fig.7

Reinforce bracket

Reinforce

bracket

E

Cassette holder

Sub chassis

Head relay

board

Joint h

Holder arm

Load arm

Joint h

tab g

Fig.5

Spring d

Load arm E washer

Cassette mecha chassis