TD

-

W

717

TNC

/

J

TD

-

W

718

BKA

/

B

/

E

/

EN

/

G

/

U

/

UT

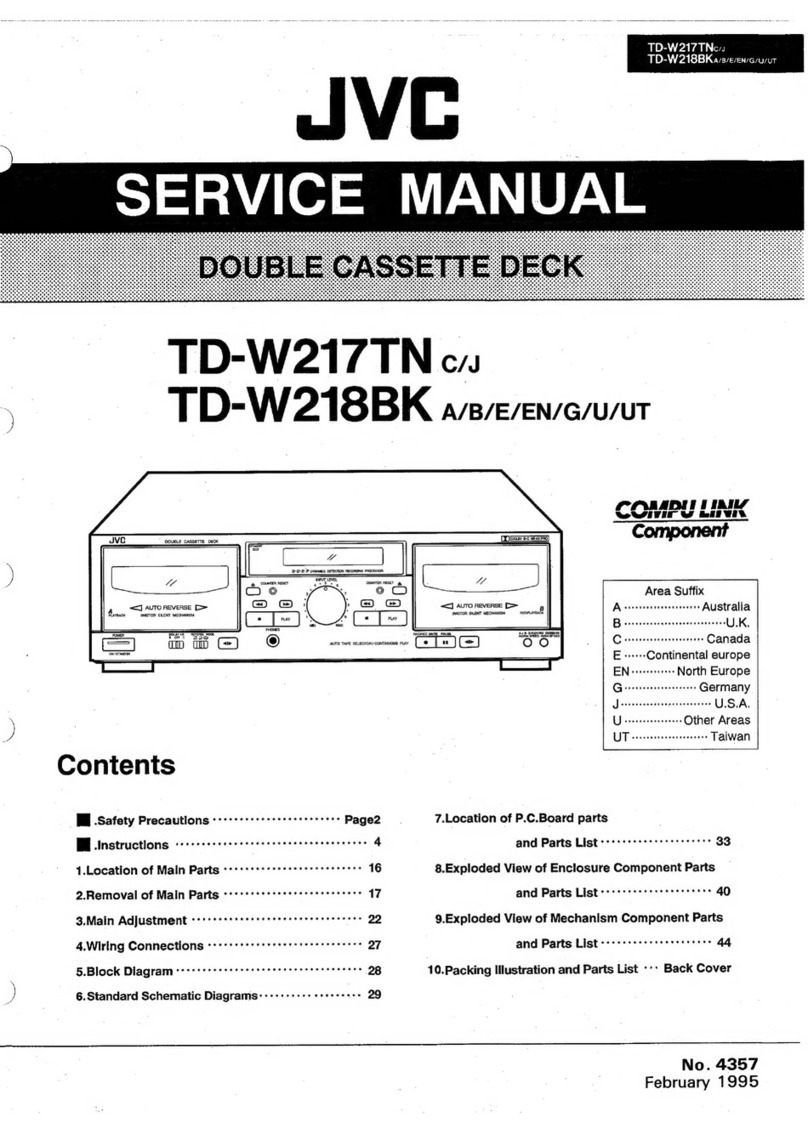

JVC

SERVICE

MANUAL

:

*

>>

:

*

:

*

:

*

:

*

:

*

:

*

:

*

:

*

::

*

:

*

::

*

x

*

^

^

*

•

•

•

«

«

«

•

»

•••••

•

•

•

(

••

(

•••••••••••

•••

»

•••

••••••

«

•

••

»

*

•

»

•

••

1

»

•

•

»

.

»

•

•

••

«

•

•

•

•

•

•

••

«

•••

••

•

••••••

* *

•

•••••

•

••

•

•

•

•

•

•

«

«

aaaaaaaaaaaaaaa

*

»

*

a

*

«

aaa

*

aaaa

«

aaaaaaaaaaaaaaaaaaafaaaaa

«

«

a

«

aaaaaa

a

a a

•

a

tail

aaaa

a t

•

a a

a

a

a a

*

i

aaaaiaaaaaaaataaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaiiiaiaiiiiaaaaaaaaaaaaaaaaii

a a a

a

a

aaa a

a

a

aaaaa

aaaaaaaaaaa

•

•

•

•

••

•

•

••

a

«

aaa

«

aaaaaa

» «

a

» »

*

« « »

a

«

*

« «

aaaaaaaaaaaaaaaaaaaaaaaaaaaa

*

»

*

aaaaa

aa

a

•

a

a

a

a a

aaaaaaa

«

•

a

a

•

a a

a

a a

a

•

•

••

•

aaa

< <

»

«

a a

*

*

a

* *

aaaaaaaaaaaaaaaaa

*

aaaaaaaaaaaaaaaaaaaaaaaaaa

<

aaaaaaaaB

*

a

*

aaa

•

a

a

a

a

a

a

a a

a

a

aaaa

a

a a

•

a

aaa

a a

»

•••••••

• •

%

•

• •

» »

•

•

»

••••

» »

••••

••••

••••••••••

•

• • • •

» »

a

a

a

aa

a

a

a a

»

a

a

a

a

a

a

a

aaa

-

a

a

aa

a a

a

a

a

a

a a

a

a

aaaa

TD

-

W

717

TN

C

/

J

TD

-

W

718

BK

A

/

B

/

E

/

EN

/

G

/

U

/

UT

rminii

iiwj

/

Component

JVC

/

/

O

/

/

o

o

/

/

o

wwr

LEVEL

a

0

-

0

0

’

^

MU

.

C

.

cif

3

-

Vi

CCM

*

J

CH

.

OWTWIWT

A

A

cowrew

»

rjgTco

>

yocw

.

)

O

"

O

CD

FWE

AMORPHOUS

MEAD

COUPU

CALIBRATION

-

<

]

AUTO

REVERSE

E

>

RUE

AMORPHOUS

HEAD

COUPU

CALIBRATION

£

<

J

AUTO

REVERSE

O

REGPLAYBACX

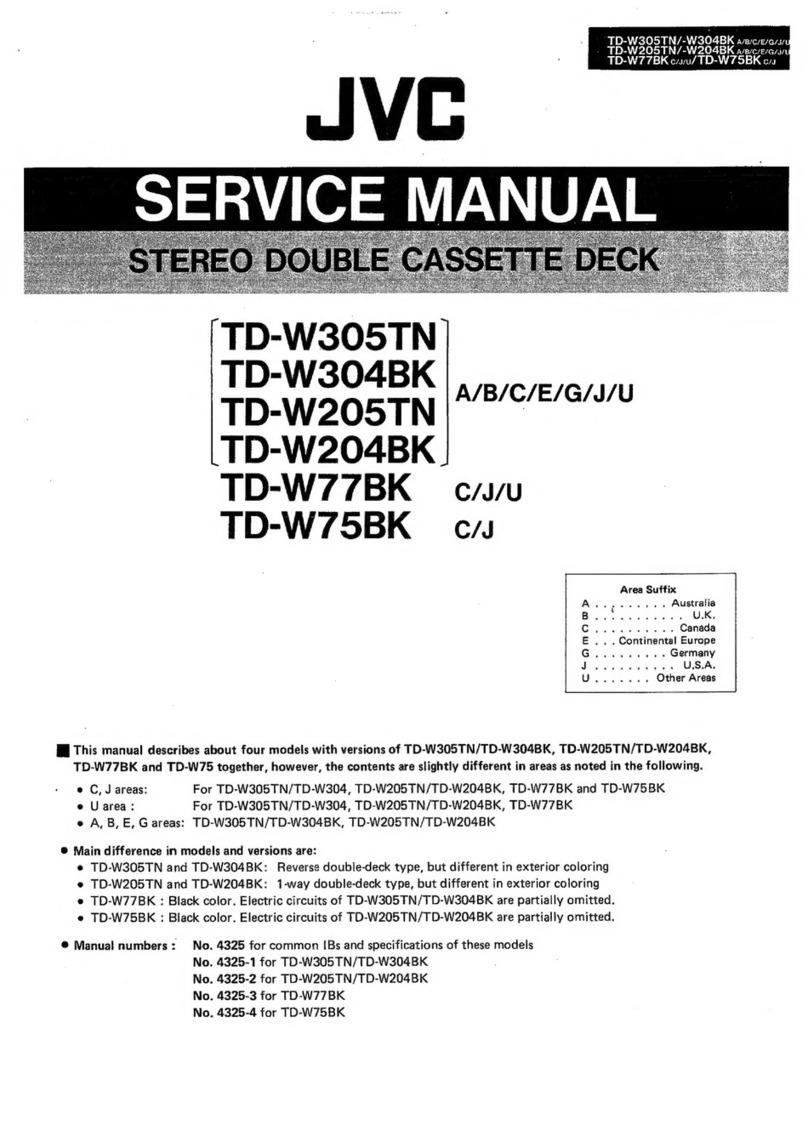

Area

Suffix

(

HD

UU

3

C

§

CA

*

—

I

wcmA

»

SAa

^

(

T

^

l

Australia

U

.

K

.

•

Canada

E

Continental

europe

North

Europe

Germany

U

.

S

.

A

.

•

Other

Areas

Taiwan

PlAV

A

PLAY

MR

news

uva

RTW

ccwna

.

•

o

a

o

•

icxixvn

—

—

MC

fHO

«

POWER

•

LAWtWF

HWfCWTI

PAUM

Dourrf

*

IVMOW

)

CAJMMO

NCQKeCHUT

*

PAUSC

B

I

»

I

If

«

»

1

O

O O

O

3

)

oO

l

*

I

1

ill

l

c

aviTAMtxy

5

aZ

3

EN

G

J

-

U

/

UT

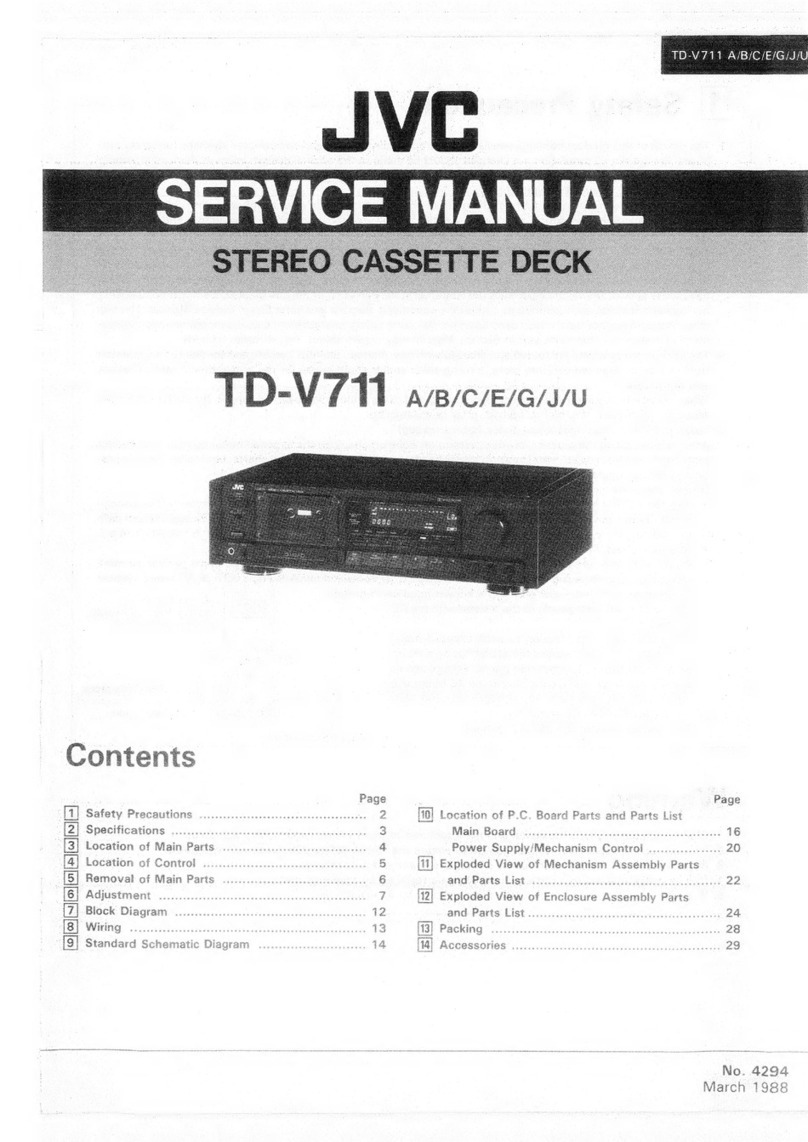

Contents

.

Safety

Precautions

I

.

Features

/

Specifications

H

.

Instructions

1

.

Location

of

Main

Parts

*

••

2

.

Remova

!

of

Main

Parts

*

•

•

3

.

Maln

Adjustment

4

.

Wlring

Connections

—

5

.

Block

Diagram

25

6

.

Standard

Schematic

Diagrams

Page

2

7

.

Location

of

P

.

C

.

Board

parts

4

30

and

Parts

List

5

8

.

Exploded

View

of

Enclosure

Component

Parts

and

Parts

List

12

40

13

9

.

Exploded

View

of

Mechanism

Component

Parts

18

42

23

and

Parts

List

\

43

24

10

-

Packing

lllusration

and

Parts

List

/

No

.

4358

June

1995